Effective sun protection requires more than just high SPF; it requires a formulation that can be easily sprayed and retained on the skin whilst being stable at rest in the bottle. We utilised our comprehensive suite of rheological and interfacial characterisation techniques to fully understand the behaviour of four leading commercial sun cream sprays.

Effective sun protection requires more than just high SPF; it requires a formulation that can be easily sprayed and retained on the skin whilst being stable at rest in the bottle. We utilised our comprehensive suite of rheological and interfacial characterisation techniques to fully understand the behaviour of four leading commercial sun cream sprays.

Our data revealed distinct performance differences:

- Boots Soltan emerged as a clear outlier in dynamic surface tension, suggesting better sprayability and wetting.

- Nivea demonstrated the highest structural integrity through a higher yield point and viscosity, favouring stability but potentially compromising sprayability.

- Amazon showed the lowest yield point, indicating ease of flow, but potentially lower emulsion stability.

By combining bulk rheology with bubble pressure tensiometry, we provide a holistic view of formulation performance, from stability in the bottle to being sprayed on the skin.

Introduction to Characterising Sun Cream Spray Formulations

Driven by a demand for convenience, consumers are increasingly turning to pump-spray sunscreens. Unlike traditional creams, the spray sunscreen delivery method presents a unique rheological compromise. The formulation requires sufficient viscosity at rest to prevent phase separation on the shelf, yet it must reduce in viscosity under the high shear of a nozzle to effectively spray into a fine mist. This is a property known as non-Newtonian shear-thinning behaviour.

In addition to this, surface tension, specifically at short surface ages, is an extremely important property governing spray and wetting behaviour. While optical and force tensiometers are commonly used for these products, they require a droplet to stabilise for around a second before taking initial measurements. This is not well-suited for applications such as spraying, which occur on millisecond timescales. To capture relevant insights at these timescales, we utilise bubble pressure tensiometry.

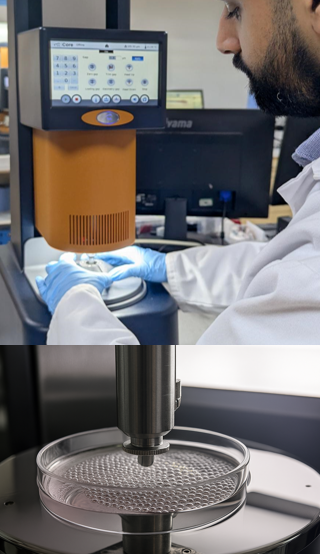

For this study, we employed four of our complementary techniques to characterise these formulations:

- Controlled Rate Viscosity Profile – We measure viscosity across a range of shear rates so we can assess flow behaviour all the way from at rest in the bottle to pumping and spraying out of the bottle.

- Thixotropy – We assess a sample’s breakdown and recovery under shear.

- Oscillation Stress Sweep – We gently ‘wobble’ the sample to gain insights into viscoelasticity and the yield point.

- Bubble Pressure Tensiometry – We measure dynamic surface tension at timescales of milliseconds to give insights relevant for droplet formation and wetting onto the skin.

Learn more about how we can support your product development

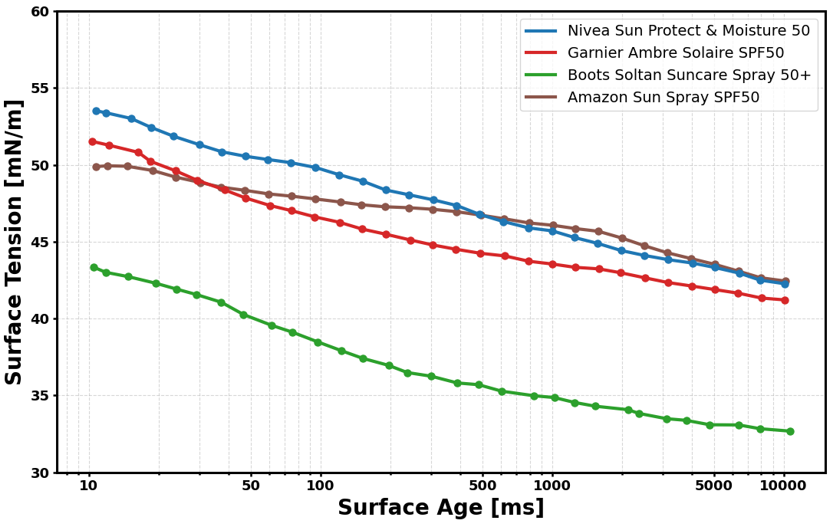

Suncream Spray Dynamic Surface Tension Measurements

Optical and force tensiometer methods are most commonly used with sunscreen samples. However, for formulations that undergo fast timescale processes such as spraying, methods must be adapted. This is due to optical tensiometry taking around a second to equilibrate and take the first measurement. This misses the millisecond timescales that really matter for spraying processes. It is desired for dynamic surface tension to reduce as quickly as possible as soon as a new interface is created. This signifies how fast surface-active molecules diffuse and adsorb at these newly created interfaces to stabilise a droplet and impart better wetting characteristics.

With this sample set, due to viscosity constraints, the formulations required dilution to 25% concentration, preventing absolute quantification of the neat commercial product. As such, this data serves as a comparative benchmark for surface-active molecule adsorption kinetics, providing insights unavailable through static optical methods. These dilutions were prepared in a beaker and homogenised through magnetic stirring.

The data shows that Boots Soltan is a distinct outlier, exhibiting a much lower surface tension and a more significant surface tension reduction rate. This suggests that, with respect to surface tension, the Boots formulation is better optimised for sprayability and effective wetting on the skin compared to the other formulations tested.

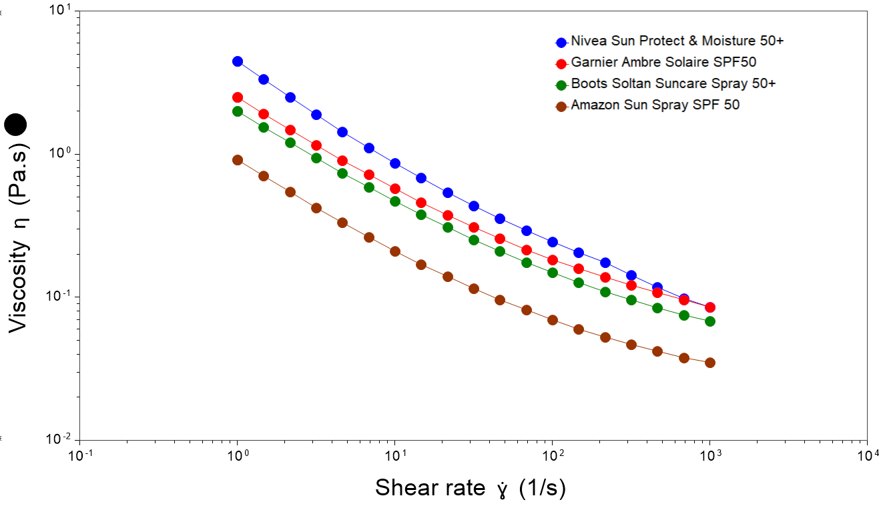

Suncream Spray Viscosity Measurements

All formulations tested in this study exhibited non-Newtonian shear-thinning behaviour. This means that their viscosity decreases as the shear rate applied increases. This is particularly important in this application, where viscosity is desired to be significantly lower when being sprayed to facilitate droplet formation, compared to when it is at rest in the bottle, where high viscosity is desired for stability. Of this sample set, Nivea exhibited the highest viscosity, while Amazon exhibited the lowest viscosity.

Table 1 – Viscosity Metrics

| Sample | Viscosity at 1s⁻¹ (mPa·s) | Viscosity at 1000s⁻¹ (mPa·s) |

|---|---|---|

| Amazon Sun Spray SPF 50 | 911 | 34.9 |

| Boots Soltan Suncare Spray 50+ | 2005 | 68.5 |

| Garnier Ambre Solaire SPF50 | 2507 | 85.3 |

| Nivea Sun Protect & Moisture 50+ | 4486 | 85.5 |

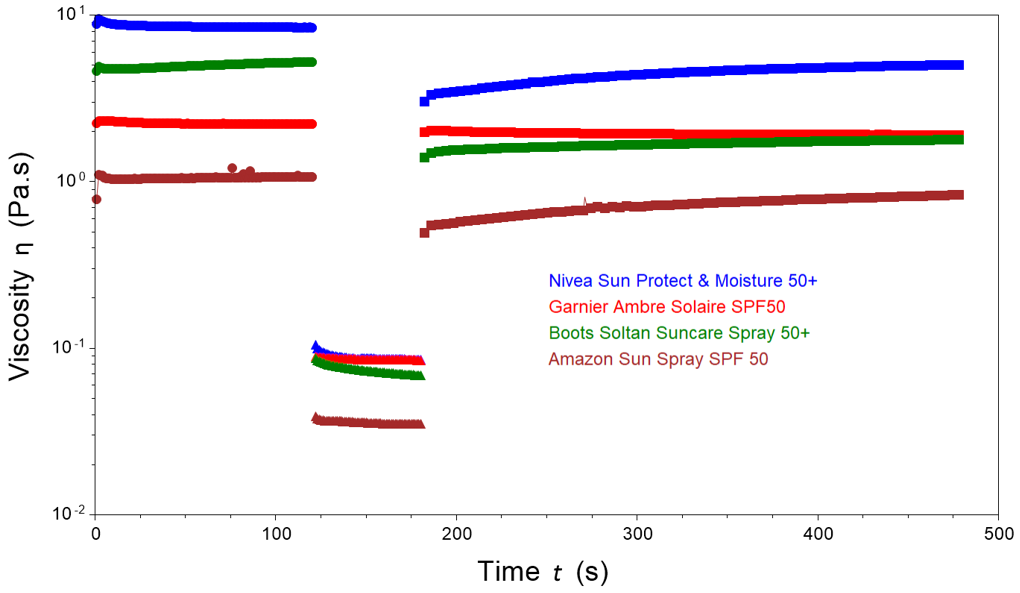

Thixotropy of Suncream Spray Formulations

We evaluated each sample’s thixotropy, a time-dependent property detailing how a material breaks down under stress and how it recovers when that stress is removed. Ideally, a sprayable suncream should exhibit a reversible structural breakdown, dropping in viscosity under high shear to facilitate spraying through the nozzle, then recovering viscosity almost instantly upon skin contact to prevent dripping or running.

We applied a three-step rotational thixotropy test, which comprised an initial low-shear phase, followed by a high-shear phase, and finally a return to low shear. All samples exhibited a significant reduction in viscosity under high shear. Following the removal of the high shear step, all samples demonstrated an instantaneous recovery; however, they did not return to their original baselines. Instead, a small time-dependent increase in viscosity was observed, with none of the samples achieving full recovery within 300 seconds.

Table 2 – Thixotropy Metrics

| Sample | Initial Viscosity (mPa·s) | High-Shear Viscosity (mPa·s) | Recovered Viscosity (mPa·s) | Percentage Reduction after High-Shear (%) |

|---|---|---|---|---|

| Amazon Sun Spray SPF 50 | 1070 | 35.1 | 834 | 22.1 |

| Boots Soltan Suncare Spray 50+ | 5240 | 68.6 | 1785 | 65.9 |

| Garnier Ambre Solaire SPF50 | 2226 | 84.8 | 1906 | 14.4 |

| Nivea Sun Protect & Moisture 50+ | 8436 | 85.6 | 5031 | 40.4 |

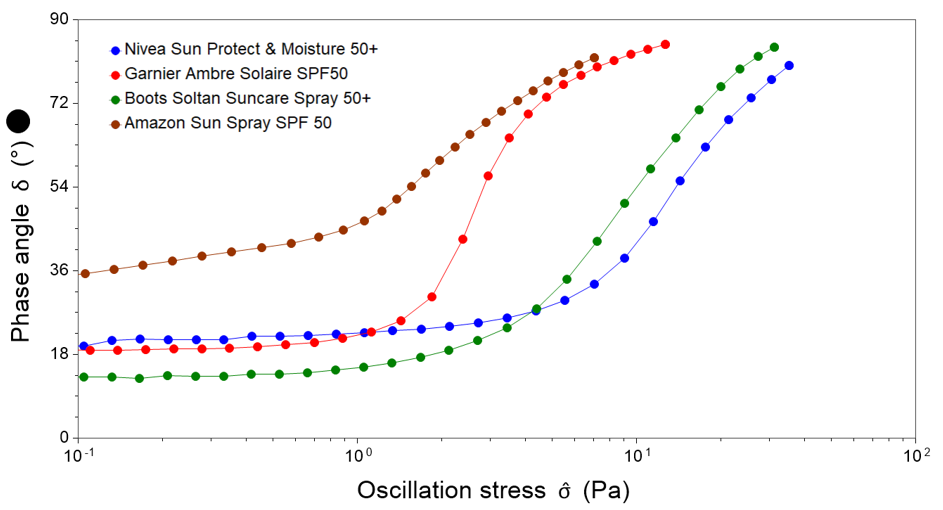

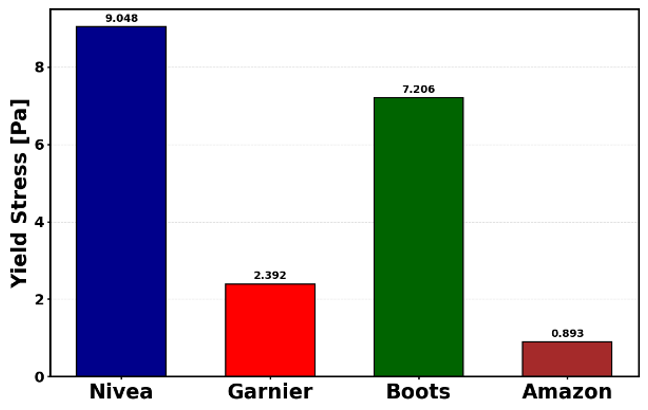

Viscoelasticity of Suncream Spray Formulations

To probe the delicate structure present within these formulations, we utilise oscillatory rheological techniques. By applying a gentle, small-amplitude oscillation, we gain insights into its viscoelastic behaviour. A key metric in this analysis is the phase angle. This metric quantifies the material’s state under oscillatory stress, with a phase angle of 0° indicating a purely elastic solid, while 90° indicates a purely viscous liquid. Additionally, we can extract the yield stress, which is the stress required to make a material flow. For sunscreen formulations, a yield stress is advantageous as it provides the structural rigidity needed to suspend the dispersed oil phase and ensure long-term stability in the bottle.

Interestingly, Boots displayed the lowest phase angle at low stresses, indicating a more elastic structure at rest compared to the others. Nivea exhibited the highest yield point, which suggests better shelf-life stability, especially combined with its higher viscosity at rest. Amazon’s lower yield point and viscosity suggest an easier actuation force for spraying, whilst potentially compromising stability at rest in the bottle.

Summary

This study has highlighted the necessity of employing multiple synergistic techniques to fully characterise spray formulations. While bulk rheology revealed important insights into flow behaviour and stability, the addition of dynamic surface tension data truly differentiated the performance capabilities. The data indicates that Boots Soltan is the standout formulation; it successfully bridges the gap between the high structural rigidity required for emulsion stability and the rapid surface-active molecule diffusion needed for optimal droplet formation and wetting on the skin. If you want to fully characterise and understand the performance of your spray formulations, do not hesitate to contact us.

Related Articles:

Predicting Formulation Stability: Advanced Insights for Suspensions and Emulsions

The Secret Factor Ruining Your Spray – Polymer Induced Normal Stress

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.