Dynamic Mechanical Analysis (DMA) is a subset of thermal analysis techniques for characterising viscoelastic properties as a function of temperature or frequency. DMA can investigate and quantify physical properties such as a glass transition, damping properties, relaxation properties and decomposition under specific environmental conditions or phase changes such as melt, curing or crystallisation.

Dynamic Mechanical Analysis (DMA) is a subset of thermal analysis techniques for characterising viscoelastic properties as a function of temperature or frequency. DMA can investigate and quantify physical properties such as a glass transition, damping properties, relaxation properties and decomposition under specific environmental conditions or phase changes such as melt, curing or crystallisation.

For materials which will be subjected to a very large range of temperatures, frequencies, or amplitudes, we can use time temperature superposition technique (TTS) to construct a ‘master curve’ that helps us understand the material’s response under extreme conditions which might not be possible to measure under typical circumstances.

To discuss our full capabilities in dynamic mechanical analysis, please feel welcome to contact us

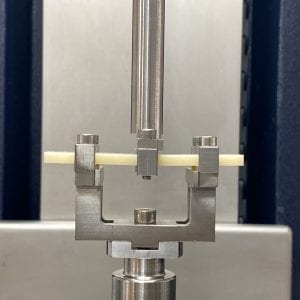

DMA is frequently used to characterise polymers in the form of bars, films or rods. Our geometries including disposable plates, cantilevers and film tension grips enable us to subject materials to shear, tension and compression. For extensional properties please contact us.

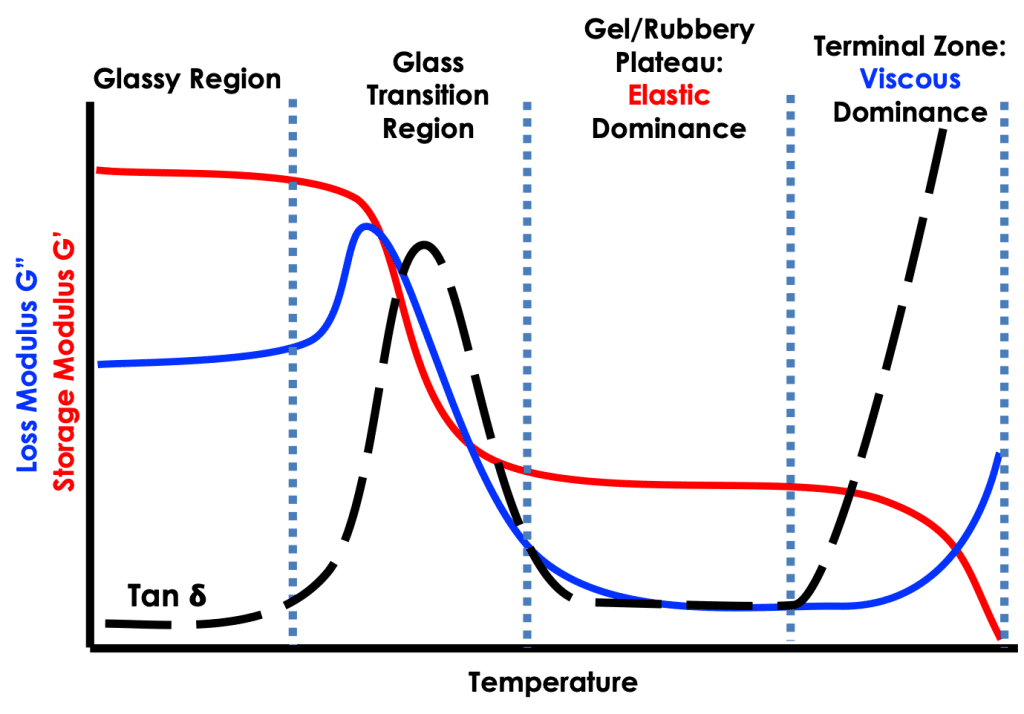

An idealised DMA plot against temperature

Under low temperatures in the glassy state, the material is a disordered an in a non-crystalline state and will be rigid and brittle. As temperature increases, the material engers the glass transition region (Tg) where the material becomes softer and more flexible – typically marked by a drop in storage modulus, increase in loss modulus and increase in tan delta. The glass transition region is not a full phase tranistion and more of a kinetic phenomenon, or sometimes referred to as a ‘second-order transition’.

Under low temperatures in the glassy state, the material is a disordered an in a non-crystalline state and will be rigid and brittle. As temperature increases, the material engers the glass transition region (Tg) where the material becomes softer and more flexible – typically marked by a drop in storage modulus, increase in loss modulus and increase in tan delta. The glass transition region is not a full phase tranistion and more of a kinetic phenomenon, or sometimes referred to as a ‘second-order transition’.

The rubbery plateau describes a region above the glass transition but below the melt, typically seen where polymer entanglement or crosslinking occurs. In the rubbery plateau, the material can exhibit large elastic deformations with relatively low stresses. Further increases in temperature may cause a phase transition or melt (Tm) where the material behaves more as a viscous liquid.