The handling properties and performance of fabric coatings are highly influenced by rheology. The choice of coating application method, processing temperatures, speeds and cure/setting conditions can be determined with a detailed rheological characterisation. An understanding of key properties such as viscosity across a range of shear conditions and temperatures, time dependent effects, yield stress and moduli can help inform decision makers in identifying optimal process variables.

Many of these properties require measurement under conditions often beyond the capabilities of a viscometer or other simple characterisation techniques. We specialise in high-powered physical measurement techniques, in controlled conditions. We help our customers exploit rheology where they may not have the equipment, expertise or time to explore these themselves.

If you’d like to arrange a short discussion about the best approaches to characterise your fabric coating, contact us now.

Why measure the rheology of your fabric coating?

Rheology is an often crucial but unnoticed property that influences stability, processability and performance in fabric coatings. The thickness and uniformity of coat, as well as its permeation into the substrate is directly a result of the rheological properties your fabric coating. A full characterisation of rheology can help predict many handling behaviours and identify optimal formulations and process variables, as well as identify the cause of complex issues.

Rheology is an often crucial but unnoticed property that influences stability, processability and performance in fabric coatings. The thickness and uniformity of coat, as well as its permeation into the substrate is directly a result of the rheological properties your fabric coating. A full characterisation of rheology can help predict many handling behaviours and identify optimal formulations and process variables, as well as identify the cause of complex issues.

However, complex non-Newtonian behaviour is a common feature found in colloids, gels, or materials made with high levels of surfactant or polymers. As development into newer and more complex fabric coatings, with highly specialised properties continues, the likelihood of encountering this behaviour grows, presenting new challenges to the formulator and process engineer.

The influence of viscosity in fabric coatings

In the context of fabric coatings, viscosity affects a myriad of vital areas including how much of your coating is delivered to your substrate, whether it’s delivered uniformly, how much it will splash under high speed, the thickness of the coat, how fast it will spread due to the effects of gravity and a whole bunch of other areas in processing, product performance and stability.

In the context of fabric coatings, viscosity affects a myriad of vital areas including how much of your coating is delivered to your substrate, whether it’s delivered uniformly, how much it will splash under high speed, the thickness of the coat, how fast it will spread due to the effects of gravity and a whole bunch of other areas in processing, product performance and stability.

High viscosity coatings need more powerful pumps to get moving and flow slowly under the effects of gravity. Low viscosity coatings are much easier to handle but don’t provide as thick a coat, thus may need re-application to achieve desired thicknesses.

Liquid coatings will fit into two classifications which describe their behaviour under shear; Newtonian or Non-Newtonian. Newtonian liquids maintain a constant viscosity independent of the shear applied. Most pump calculations will presume your material is Newtonian in behaviour, which can cause issues when you attempt to vary processing speed. Non-Newtonian liquids change their viscosity with increasing shear. This ‘double-life’ of a Non-Newtonian liquid can present some desirable properties with control of applied shear.

Shear thinning is the most common non-Newtonian rheological behaviour observed, where viscosity decreases as a function of increasing shear rate/shear stress. This is ideal for coating behaviour, where you want the material to be easy to spread and handle, but to thicken up and stay in place once deposited onto the substrate. Without a careful understanding of how much your viscosity changes due to increasing shear, it is possible to inadvertently deliver more coating than intended when processing speeds are increased.

Shear thickening much more rare, and describes when the viscosity of the fluid increases with increasing applied shear. This behaviour is vital in the development of fabric treatments for body armour, where flexibility is needed during day-to-day product use and inflexiblity necessary to prevent damage from bludgeoning or penetration/piercing by stabbing or bullets. It does however impose strict limits on process speeds without significant investment into high powered production lines.

Viscoelasticity in textile coatings

Viscoelasticity has been shown to play an important role in the fabric coating process. Viscoelasticity is the phenomenon where a liquid exhibits a degree of elastic, energy-storing “bounce-back-ability” in addition to the simple energy-dissipating flow we would obtain with a normal liquid. This behaviour is seen clearly in novelty products such as silly putty and slime but is also prevalent in some thickened coating formulations.

Viscoelasticity typically manifests when sudden deformations are imposed, such as in the nip between rollers or as a coating is forced into the weave of a textile by a knife over roller situation. It is in these short-timescale events that the elastic response results in the coating leaving ribbing defects or resists penetration into a fabric. Thickeners such as high molecular weight polymers intended to stabilize a suspension or improve film-forming properties can impart unwanted viscoelasticity into formulations.

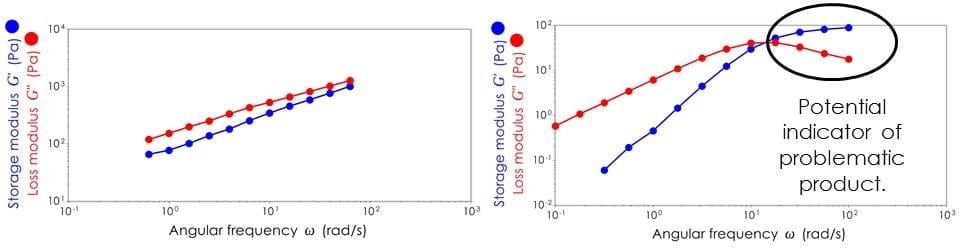

Oscillatory frequency sweeps and Normal stress profiling are two methods that can reveal such behaviours. An oscillatory frequency sweep applies a highly defined ‘wobble’ to a sample, over decreasing time-scales to see whether the sample bounces back like a solid, or flows like a liquid.

In the example above, both samples display viscoelasticity however the sample on the left maintains liquid like behaviour across a range of timescale deformations. The sample on the right undergoes a distinct change in rheological behaviour when the timescale of deformation becomes very short. Instead of displaying liquid like flow behaviour, the sample will ‘bounce-back’ like a solid. This can be potentially quite problematic as you increase processing speeds.

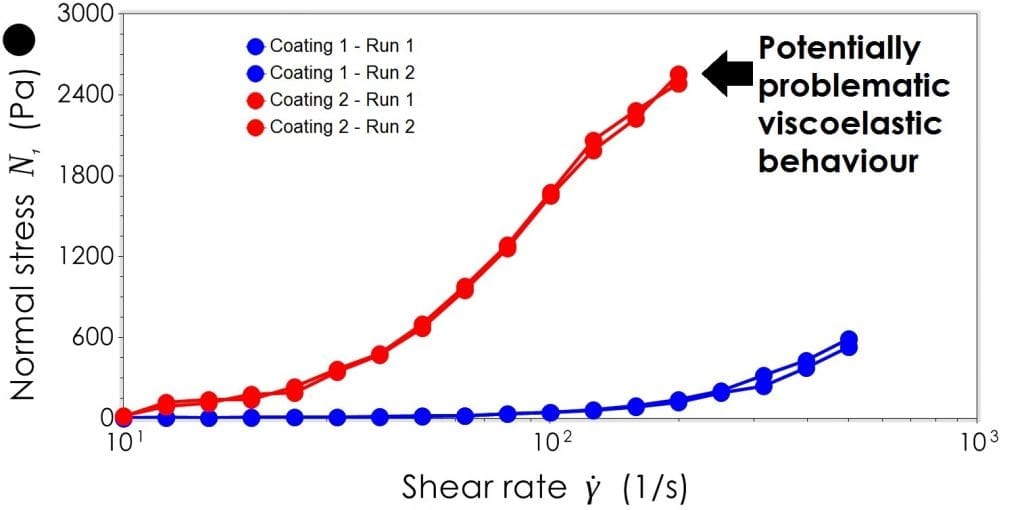

It is also possible to also identify potential viscoelastic effects from a viscosity profile using a high-powered rheometer by looking at Normal stress generation. Normal stress refers to an upwards force that viscoelastic materials generate under shear. The more rapid this growth in Normal stress, the more pronounced the viscoelastic effect. In the example below Coating 1 shows a less prominent growth in Normal stress generation over the same shear rate ranges, compared to Coating 2. Normal stress measurements can identify potentially unwanted viscoelastic properties that are not evident from simple viscosity profiling.

Often there is no single cause to an observed issue and it is important to look at a variety of metrics in context. Our lab has decades of experience testing complex materials, and explaining results in a clear and concise manner, to all levels of scientific familiarity. We offer a complete characterisation, and results consultation service with full, ongoing support.

For a discussion about using rheology to assist with the development and understanding of your fabric coating. Please contact us now.