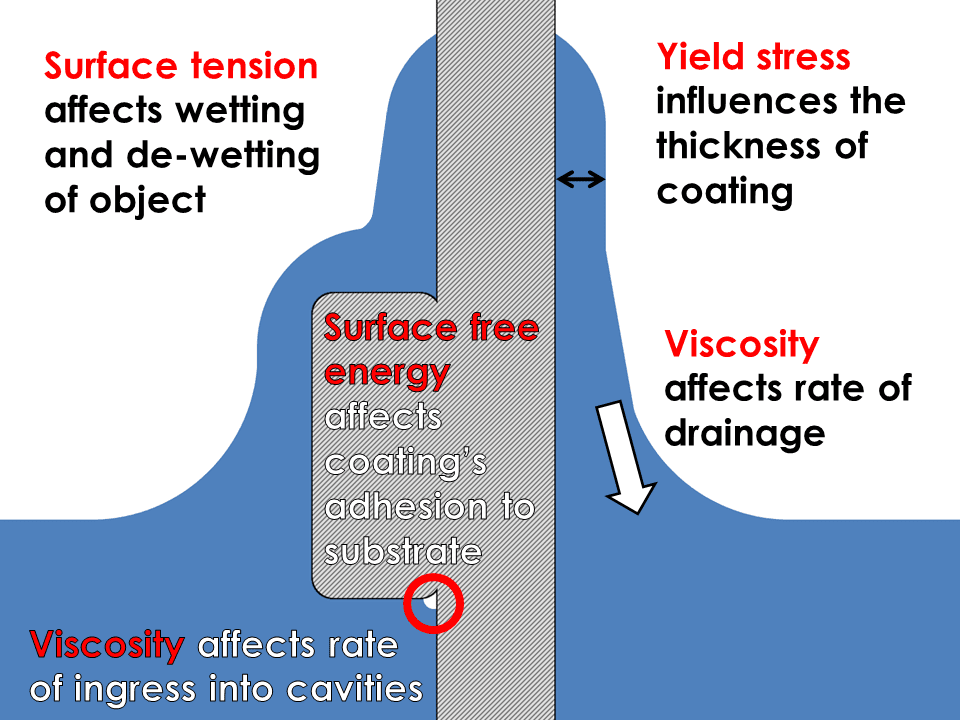

Rheology and surface tension influence the performance of a dip coating/immersion process in a number of ways. Coating thickness, rate of drainage, ability to ingress into cavities, avoidance of coverage gaps, film thickness and other common coating process issues can all be predicted with an understanding of a product’s physical handling behaviour under defined conditions. Simple viscometry methods, and drop shape analysis techniques which don’t consider the dynamic nature of surface tension, can overlook important nuances of an issue and potentially misrepresent their true cause.

Contact us to discuss your dip coating issues and which rheological and surface analysis techniques can help.

Dip coating (or saturation / immersion coating) is one of the simplest methods to modify the surface of a material and is well suited to objects with complex geometries. Indeed, it’s one of our favourite ways to get ketchup onto our french fries, and is also used to keep vital tools and components protected in the workshop, kitchen and bedroom… Results from dip coating are limited primarily by the wetting and rheological properties of the coating. In general, viscosity determines the ease of coating, initial coating thickness and rate of drainage. Contact angle determines the ‘wettability’ of the coating onto the substrate and yield stress is one of the key factors when controlling the thickness of the coating.

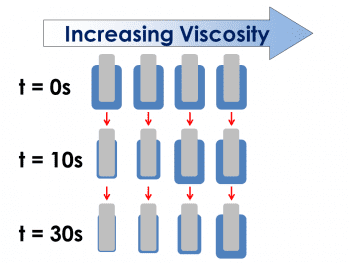

Viscosity – Initial thickness and speed of drainage

A high viscosity slows the rate of sloughing off/dripping from the substrate but also slows the rate of ingress into crevices during dip coating, thus setting a rate limiting step to speed of submersion/withdrawal. Materials with a low viscosity flow much more easily. For objects with complex geometries, it is important to allow the coating sufficient time to flow into cavities, around corners and travel through tunnels. If the rate of immersion or withdrawal is too fast, this can manifest in a number of issues such as bubbles which then pop to create gaps, or an uneven coat.

A high viscosity slows the rate of sloughing off/dripping from the substrate but also slows the rate of ingress into crevices during dip coating, thus setting a rate limiting step to speed of submersion/withdrawal. Materials with a low viscosity flow much more easily. For objects with complex geometries, it is important to allow the coating sufficient time to flow into cavities, around corners and travel through tunnels. If the rate of immersion or withdrawal is too fast, this can manifest in a number of issues such as bubbles which then pop to create gaps, or an uneven coat.

The behaviour of Newtonian materials is relatively simple and straightforward; their viscosity doesn’t change due to the influence of shear rate. However, the majority of coatings display non-Newtonian shear thinning behaviour, meaning their viscosity decreases with increasing shear rate making prediction and control of the coating more challenging. Determination of viscosity at defined shear rates across a wide range is often not possible with simple viscometers.

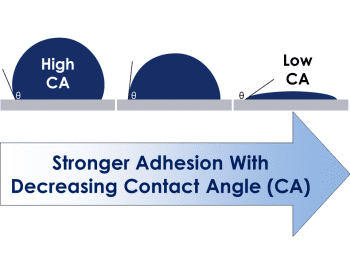

Contact Angle – Preference to wet substrate

Low contact angles between coating and substrate indicate good wetting between the materials, and is generally desirable for a dip coating process. The ingress of coating material into cavitations or crevices of the substrate by capillary action, is directly influenced by surface tension of the coating material and its preference to wet the substrate. Poor wetting can promote the formation of bubbles, or differences in coating thickness, and even gaps. However, this property can be advantageous in precise control of applying coatings exactly where needed – surface pre-treatment can either be used to improve or impair the wetting of coating onto substrate by altering the surface free-energy of the substrate.

A static contact angle measurement provides a measurement of interfacial forces between the liquid, air and substrate once they have reached equilibrium. A dynamic contact angle measurement shows how contact angle changes as a function of either time or tilt/gravity which can be relevant when modelling high-speed processing of highly viscous materials. If a liquid takes a longer time to reach its equilibrium contact angle, this may indicate a limiting factor for withdrawal speed.

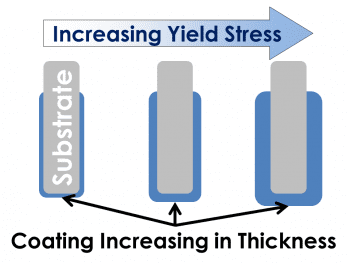

Yield Stress – Stability and Coating Thickness

The final thickness of a dip coat depends on its ability to resist sloughing off, and yield stress is one of the key determining factors. If you’ve ever wondered why mayonnaise is easier to spread than honey, and coincidentally forms a thicker coating at equilibrium, then read on.

The final thickness of a dip coat depends on its ability to resist sloughing off, and yield stress is one of the key determining factors. If you’ve ever wondered why mayonnaise is easier to spread than honey, and coincidentally forms a thicker coating at equilibrium, then read on.

The yield stress of a material is the stress at which it displays significant flow behaviour. I.e. how hard does an elastic/viscoelastic material need to be pushed until it starts behaving like a liquid. In the context of a dip coating, gravity acting upon the mass of the coating applies a constant shear stress causing it to flow. Flow continues until the weight of the coating reaches equilibrium with the yield stress. The challenge of working with a dip coating that has a yield stress, is ensuring that it is low enough that you can encourage flow to areas where you need coverage, but high enough that you achieve a desired coating thickness.

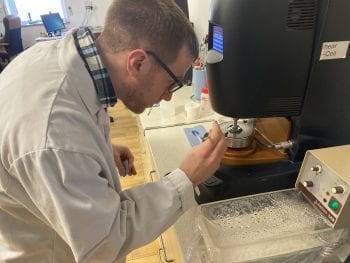

Complex Behaviours Explained In An Accessible Manner – Physical Analyses in Dip Coating Brought to You By the Centre for Industrial Rheology

Complex Behaviours Explained In An Accessible Manner – Physical Analyses in Dip Coating Brought to You By the Centre for Industrial Rheology

Our lab specialises in the characterisation of difficult to measure materials, and making physical analyses practical, simple and accessible. We work with our customers to identify appropriate methods and techniques that best describe the physical behaviours of their products under specific conditions. We can explore temperature dependencies, thixotropic recovery rates, viscoelasticity and a number of other physical behaviours.