The use of dynamic surface rheometry to monitor the air-curing of nail varnishes can show differences in behaviour during and after film formation. This technique can be used as a tool to benchmark materials against each other and provide additional scientific evidence to reinforce claims. In all the tests completed, nail varnish A, the ‘traditional’ air-cured nail varnish, shows properties that were potentially less desirable compared to the other products tested e.g. may be more prone to chipping. Nail varnish B, marketed as long-wearing, showed properties that suggested that the product would provide a longer-wearing product compared to the other samples tested.

The use of dynamic surface rheometry to monitor the air-curing of nail varnishes can show differences in behaviour during and after film formation. This technique can be used as a tool to benchmark materials against each other and provide additional scientific evidence to reinforce claims. In all the tests completed, nail varnish A, the ‘traditional’ air-cured nail varnish, shows properties that were potentially less desirable compared to the other products tested e.g. may be more prone to chipping. Nail varnish B, marketed as long-wearing, showed properties that suggested that the product would provide a longer-wearing product compared to the other samples tested.

Nail varnish is arguably one of the staples of a make-up bag, and the annual market for nail varnishes is worth over USD 14 billion and growing. However, although these beauty items may be commonplace, their fluid and chemical compositions are extremely complex. For example, colour, smell, evaporation rate, texture, thixotropy, viscosity, nail adhesion, tackiness and longevity upon curing all require attention.

Contact us to arrange a lab tour and discuss rheological techniques with our experts

Broadly speaking, nail varnishes can be classified according to solvent choice (aqueous or non-aqueous) and film-forming method (UV or air-curing). The first nail varnish formulations contained non-aqueous, volatile solvents that contained a suspension of a film-forming polymer, often nitrocellulose. After application of the bulk varnish to the nail using a brush, the solvent evaporated and the nitrocellulose polymer was left behind, leaving a residual thin film on the nail that usually contained a pigment.

As nail varnish technology has progressed new products have come to the market that claim short curing times, often within 60 seconds, or are marketed as vegan. In addition there is a significant push towards nail varnishes that are more environmentally friendly and use aqueous or ‘green’ solvents, as well as nail varnishes that cure under UV irradiation rather than in air. UV-cured nail varnishes are often perceived as being more long-lasting and chip-resistant than air-cured products and are gaining popularity.

In terms of customer perception, cure time, quality of coverage, chip resistance and ease of application are all important and may impact upon whether a customer will repeat-purchase or recommend a particular product.

Dynamic Surface Rheometry

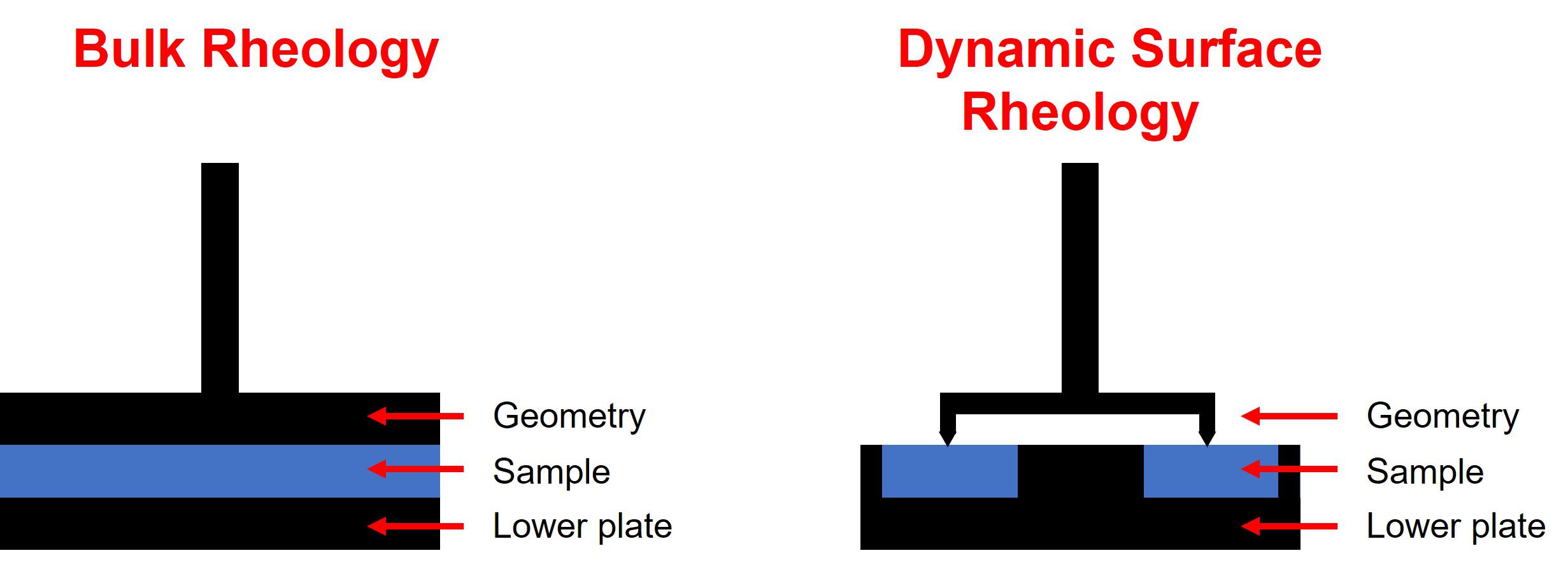

‘Traditional’ rheology involves placing a sample between two plates, and measuring who the whole sample moves. This is also referred to as ‘bulk rheology’. Dynamic surface rheometry involves loading the sample into a trough and then placing a ring geometry on the surface of the sample. This means that the sample is not fully enclosed and is open to the atmosphere therefore formation of films due to curing or drying can be investigated.

Measuring film-forming properties

To this end, we used our dynamic surface rheometry attachment to compare and contrast the drying behaviour of four nail varnishes. All nail varnishes were air-cured rather than UV-cured.

- Nail varnish A: ‘traditional’ nail varnish

- Nail varnish B: long-lasting wear nail varnish

- Nail varnish C: rapidly drying nail varnish

- Nail varnish D: vegan nail varnish

- Nail varnish E: gel nail varnish

All nail varnish samples were loaded into the base-geometry such that the minimum volume of nail varnish to fill the well was used. The dynamic surface rheometry attachment was then lowered so it was just in contact with the surface. In all cases the base-plate was heated to 25 °C and the samples were open to the air i.e. covers were not used.

The first experiment was a time sweep, where the oscillation stress was kept constant and the nail varnish was allowed to cure for 3600 seconds (1 hour). After this time, an oscillatory stress sweep was undertaken to determine the yield stress for the film formed.

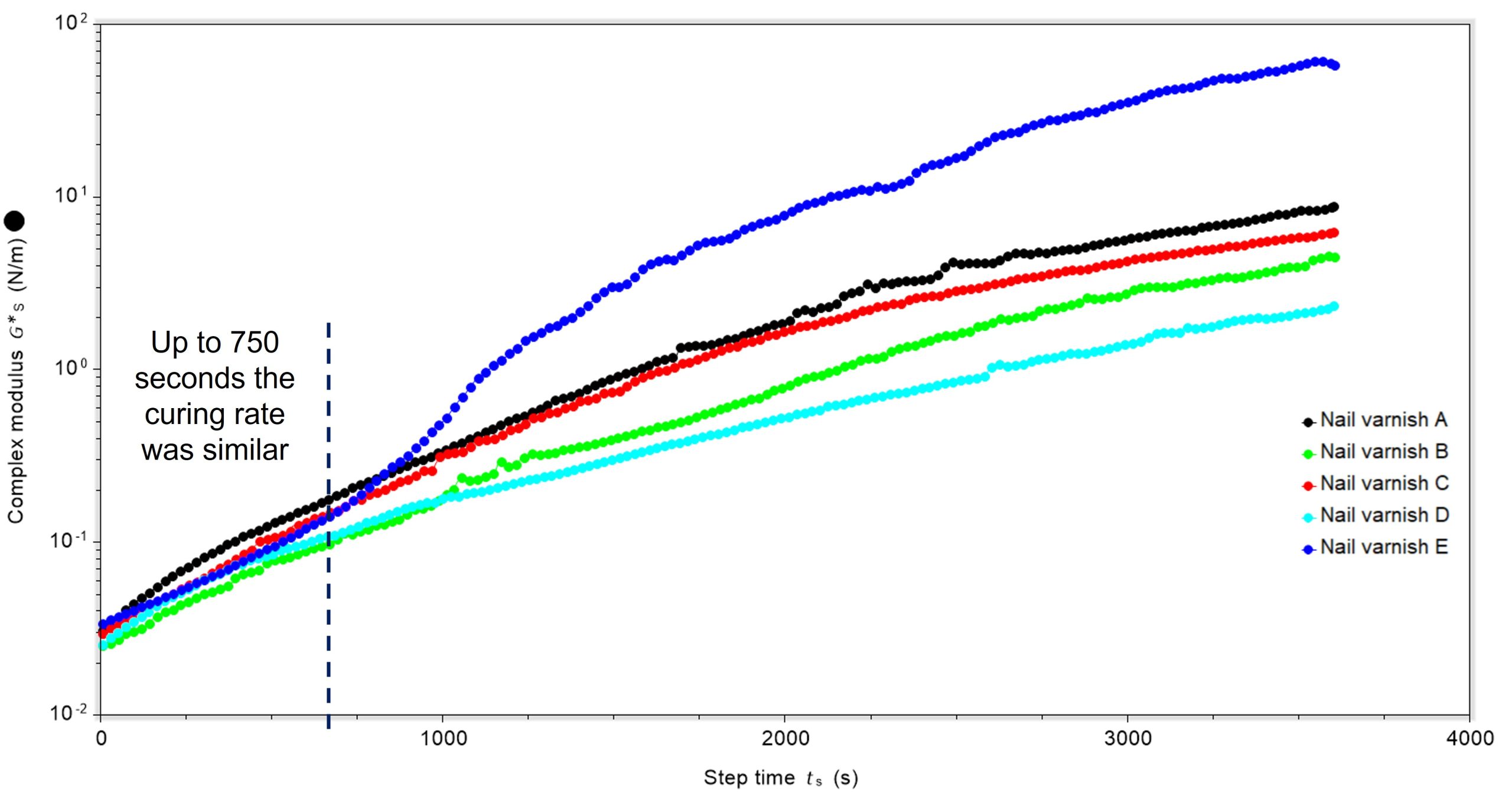

All samples had a similar initial complex modulus, which increased as the film was formed on the surface and the material cured, Figure 1. In addition, the rate of cure for all samples was broadly similar for the first 750 seconds. After this time, nail varnish E (marketed as an air-cured gel) showed a considerable increase in complex modulus, becoming more rigid at a much faster rate than the other samples tested.

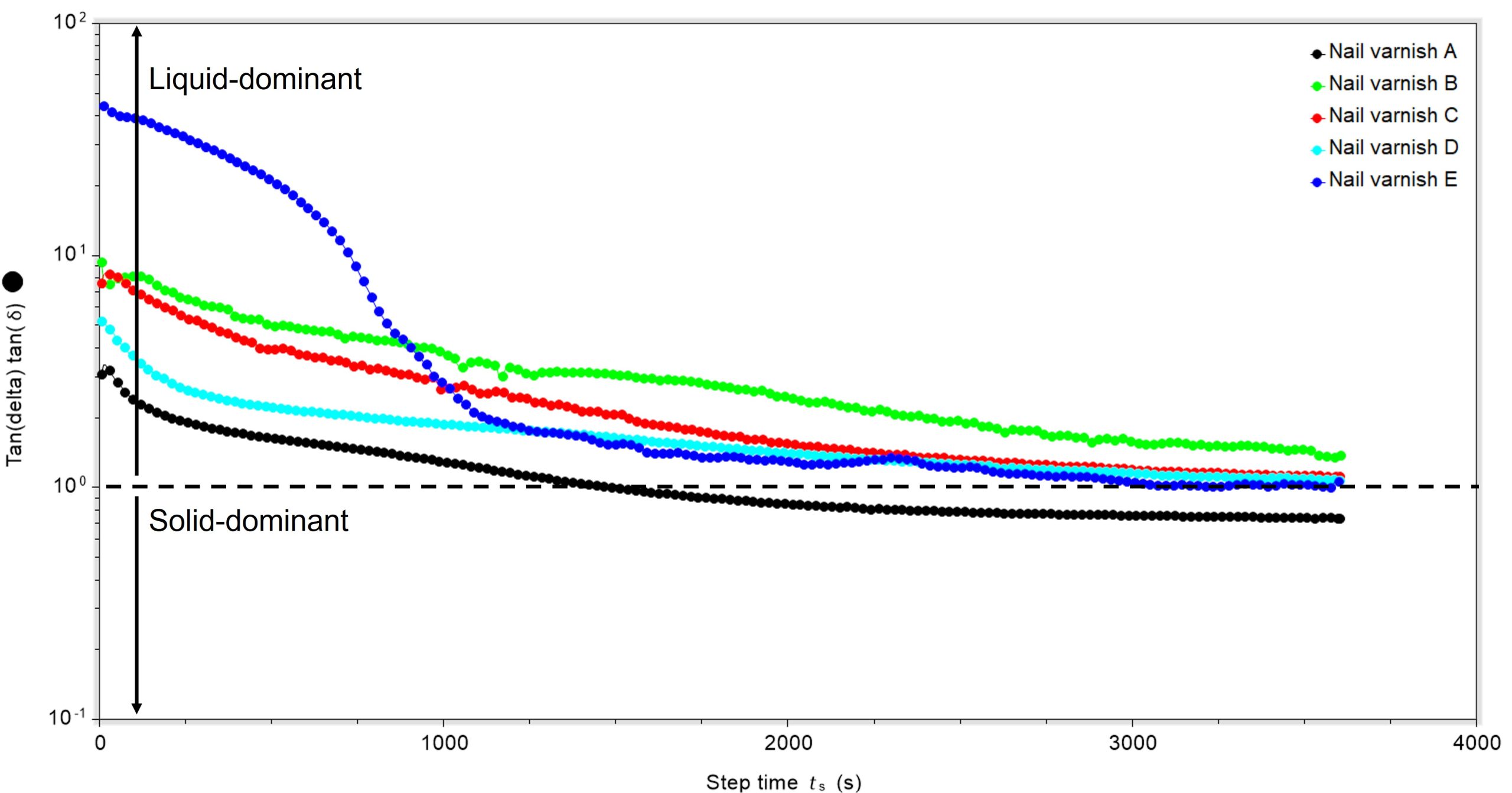

In addition to the complex modulus, considering the tan δ value provides additional information about how solid-like or liquid-like a sample is, or in other words the dominance of elastic or plastic behaviour. Tan δ is calculated by dividing the loss modulus (G’’) by the storage modulus (G’):

Tan δ = G’’/G’

If tan δ has a value of over 1, the behaviour is liquid-dominant and if tan δ has a value of below 1, the behaviour is solid-dominant. When tan δ equals 1 the storage and loss moduli are equivalent, i.e. the point at which the moduli cross. Tan δ can show how a material’s structure changes over time, similar to complex modulus data. However, although complex modulus data shows rigidity changes over time, the tan δ value reveals if this change is leading to a change in solid- or liquid-dominance.

The tan δ data clearly show that initially nail varnish E is the most liquid-dominant compared to the other nail varnishes due to the highest value of tan δ, i.e. any deformation cannot be readily recovered and the material is plastic-dominant, Figure 2. The tan δ plot also reveals that as nail varnish E cures it becomes more elastic (i.e. the solid-like properties increase) due to the decrease in value. However, nail varnish E never becomes solid-dominant and the tan δ value never drops below 1. The same is true for nail varnishes B, C and D, with closer scrutiny showing that for nail varnish B the lowest tan δ value achieved during this experiment was 1.38. This is interesting, as nail varnish B is marketed as being ‘long-lasting’ therefore the higher tan δ value suggests that nail varnish B could flex and deform with the nail bed, which could give it long-lasting properties as it can bend to accommodate external stresse. The only nail varnish tested to form a solid-dominant film was nail varnish A, which had a final tan δ value of 0.74.

Although we talk about solid- and liquid-dominance, it is important to bear in mind that there is still a film formed and whether it is solid- or liquid-dominant is a reflection of the film’s behaviour. This is important, as formation of a film that is solid dominant, and potentially less flexible, may lead to a covering that is more prone to chipping as it cannot deform to facilitate any movement by the nail.

Oscillation stress sweep to investigate film strength

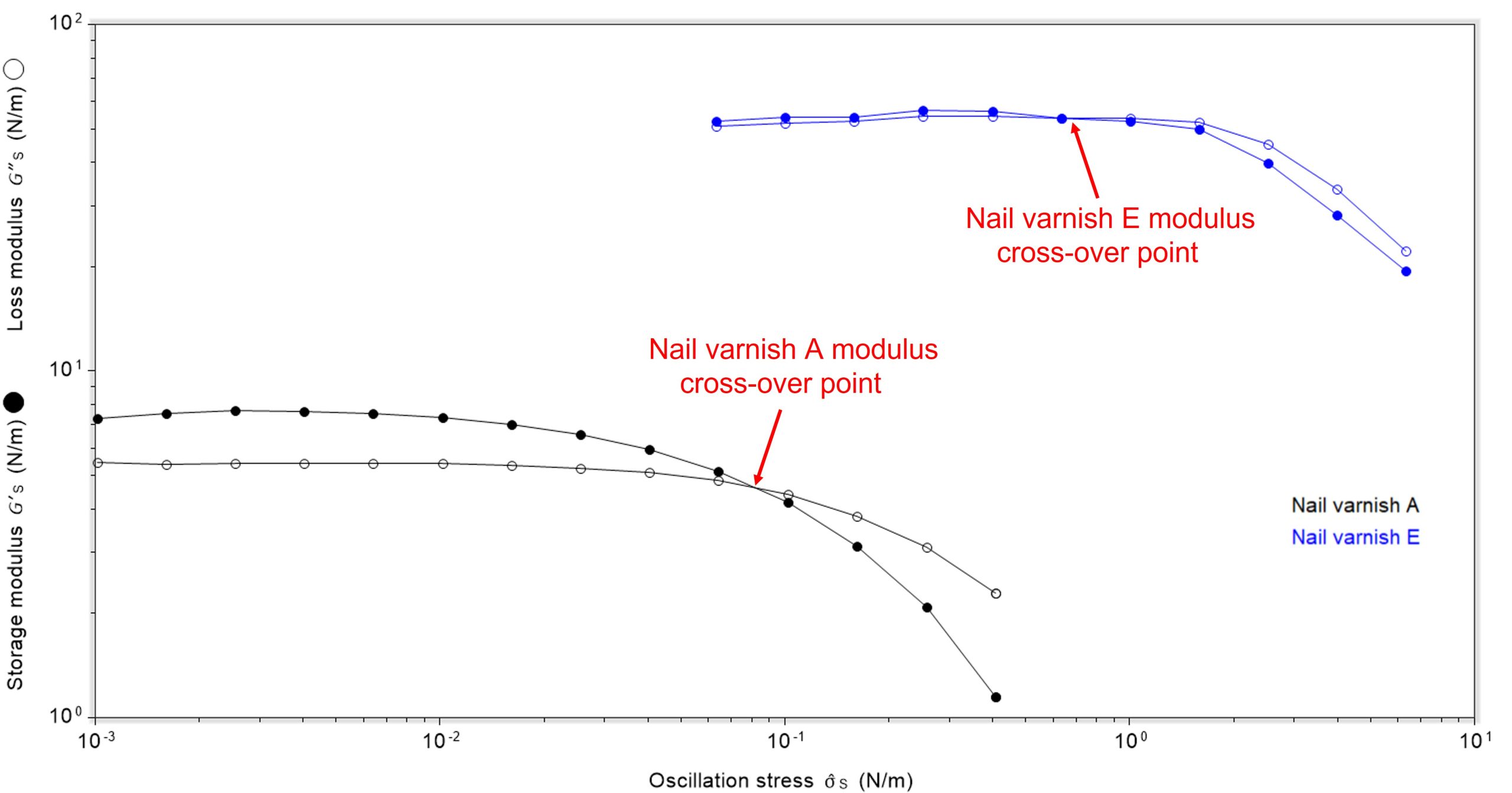

Once the films had been formed, the strength of the film was tested to see if there were any significant differences. To aid clarity, only data for nail varnishes A and E is included as they showed a clear modulus cross-over point, Figure 3. Nail varnish A yielded under lower stress than nail varnish E. This difference in yield stress may lead to differences in behaviour; for example, nail varnish A may be more brittle than nail varnish E so may chip more readily. This also ties-in with the tan δ value in Figure 2, which shows nail varnish A becomes more solid-dominant compared to the other samples.

Summary

The use of a dynamic surface rheometry attachment has allowed for probing into the behaviour of nail varnishes that cure in the air. Key findings include:

- In all cases the complex modulus increases over time and the initial rate of cure are similar between the samples. Changes in cure rate become apparent after 750 seconds.

- In all cases the tan δ value decreased over time. However, tan δ only went below 1, showing solid-dominance, for sample A. All other samples maintained liquid-dominance throughout the experiment.

- The yield stress of the films formed after 3600 seconds gives information about their strength. Nail varnish A required less stress to break the film compared to nail varnish E.

A conclusion that could be drawn is that nail varnish A, the ‘traditional’ air-cured varnish, forms a more rigid film that has a lower yield stress that the other nail varnishes. This may mean that nail varnish A is more prone to chipping or delamination as it cannot move and flex with the nail bed, potentially leading to shorter wear-time overall. In addition, the higher tan δ value to nail varnish B (marketed as long-wearing) suggests that nail varnish B could flex to accommodate external stresses and changes to the nail, which could contribute towards the long-wear properties. Nail varnishes C, D and E were broadly similar in terms of behaviours investigated, and fell between nail varnishes A in B in terms of rheological properties.