The rheology of thermosensitive injectable polymer hydrogels is an important area of interest for medical professionals looking to improve API delivery to target tissues. The Sol-Gel transition of a polymer hydrogel must occur at body temperature under physiological pH and salt content, and being able to test whether this occurs ex-vivo greatly helps accelerate the development and design of the polymer hydrogel.

The rheology of thermosensitive injectable polymer hydrogels is an important area of interest for medical professionals looking to improve API delivery to target tissues. The Sol-Gel transition of a polymer hydrogel must occur at body temperature under physiological pH and salt content, and being able to test whether this occurs ex-vivo greatly helps accelerate the development and design of the polymer hydrogel.

In addition to designing a carrier material that will gel under specific conditions, the material must also resist high shear conditions such as when being syringed through a small gauge needle. Contact the rheology lab to arrange a virtual tour of the lab and discuss which of our capabilities and expertise you can rely on to accelerate your thermosensitive injectable polymer hydrogel development.

Contact our lab to arrange a short discussion about how we can help.

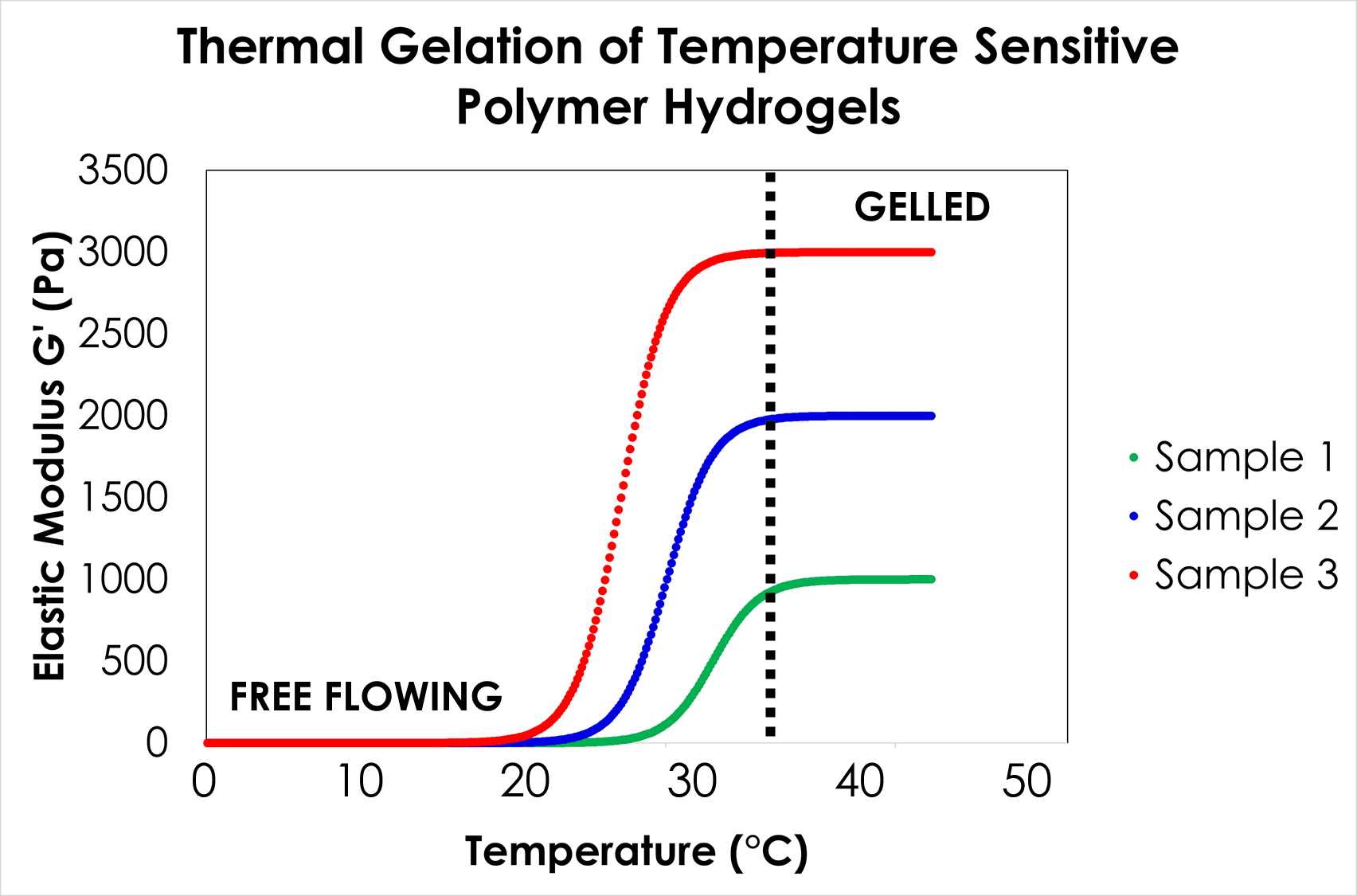

Materials that can reversibly gel upon the application of increased temperature have exciting uses in therapy since they can be easily manipulated and delivered to a target tissue, then due to surrounding heat transfer from the body, will gel. This gelation causes the material to resist clearance from the body, prolonging its presence at the target site and altering the release kinetics of the API. Many thermosensitive polymers such as poly(N-isopropyl acrylamide) (PNIPAM) gel at physiologically relevant temperatures (in this case 32°C).

Quantifying temperature-driven changes in thermosensitive injectables

The thickening of a material due to temperature can be quantified by looking at changes in viscosity as the temperature is swept or held at a target value. However, viscosity profiling is not the best method for looking at structural changes since the shear applied during a viscosity test may damage or even destroy the very structure that is being formed.

In oscillatory rheology testing, the sample is ‘wobbled’ very gently back and forth and either stress or strain is measured. The test itself is minimally disruptive and provides more relevant information for structural changes. For gelled materials, it is more relevant to describe its physical properties in terms of structural strength, rigidity and deformation in response to increasing stress/strain.

In an oscillation temperature sweep we can plot structural changes as a function of increasing or decreasing temperature, and quantify differences between benchmark formulations, helping formulators get a simple overview of how their decisions have affected gelation behaviour and gel structural properties.

Viscosity: syringeability and stability of thermosensitive injectable polymer hydrogels

The ease at which an injectable can be evacuated from a syringe (its “syringeability”) is heavily affected by the viscosity of the material. High viscosity injectables require large gauge needles due to the difficulty in administration but can be significantly more discomforting to the patient.

Unfortunately for the patient, a high viscosity gel is very good at keeping particles (such as APIs) suspended as the particles encounter more resistance when settling/floating out. In an ideal scenario the perfect injectable has a high viscosity under low stress/low strain conditions to inhibit movement of particles, but a low viscosity under high stress/high strain conditions such as during injection, so it is easier to handle. A shear rate sweep of viscosity can help identify whether an injectable meets these requirements. There are also more empirical tests such as our syringeability test run on a texture analyser that directly measures the force required to evacuate a needle at a set rate. You can read more about the syringeability test here. It is possible for us to characterise a material, inject it through a syringe and then test to see whether its properties have changed.

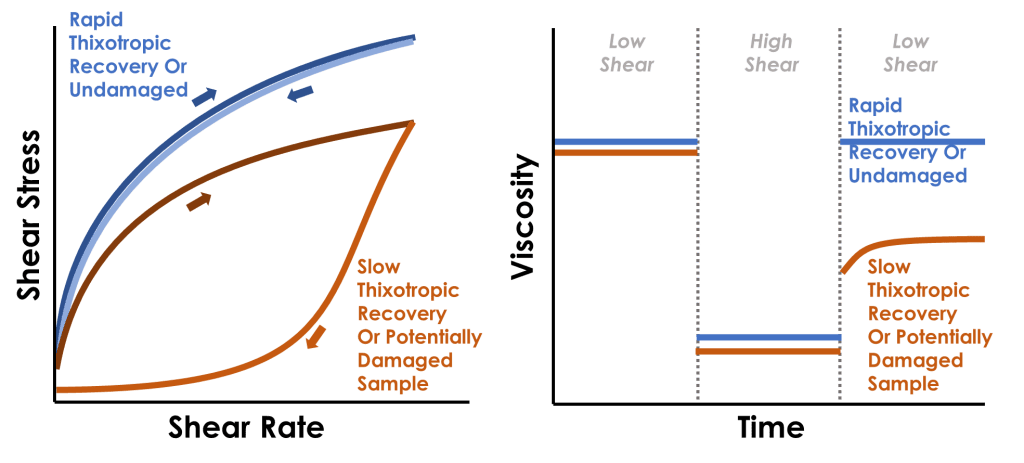

The application of high shear, such as being forced through a small gauge needle, to a polymer hydrogel can irreversibly damage the hydrogel potentially affecting its sol-gel transition and ultimately limiting its effectiveness as a carrier material. A thixotropy test can be used to investigate whether changes in the viscosity of your sample are a result of recoverable slow-acting thixotropic behaviours, or potentially due to non-recoverable damage to your sample due to high shear. Damaged samples will have different rheological properties after shear has been applied.

In a thixotropic loop test, as shown above, a sample is first subjected to a shear rate ramp from a low shear rate to a high shear rate, held at its peak for a period of time, and then slowly swept back down into low shear rates. The sample displaying rapid thixotropic recovery should almost plot a curve that exactly overlays the upsweep indicating no time dependent delay in recovery. The slow thixotropic recovery, or potentially damaged sample will show that the downsweep follows a deviant path. The bigger the deviation, the longer the recovery or potentially worse the damage.

On the right hand side of the image above, we have a three step test, where the sample is subjected to a low shear condition for a set amount of time, then a high shear condition, then back to a low shear condition. In this test its more obvious to see the time based component of recovery, and if the sample ever recovers to its pre-high shear condition.

Expert characterisation – Demonstrating thermosensitivity of injectable polymer hydrogels

Whether you are looking for characterisation of mixed polymer solutions, novel polymers or simply generating claims support data for regulatory submission, we have a variety of tools and methods to reliably describe rheological behaviour in a repeatable, objective and accessible manner. All our testing reports include ongoing support to ensure that the data generated can be exploited fully for any number of use cases, from formulation, processing or quality.