Our lab can provide a comprehensive hand sanitiser testing toolkit for characterisation of key quality attributes. Compare the functionality of polymers and thickeners, demonstrate superior sensory properties or gain a fast-track, no human-contact alternative to sensory panel testing.We can also provide testing services for formulation benchmarking or market mapping. Quantify stickiness and tackiness, identify a ‘window’ of acceptable behaviour for your pump dispenser or investigate physical properties which elude simple characterisation methods.

Contact us for an overview of our capabilities and ideas on how we can help you

Testing Toolkit for Hand Sanitisers

Hand sanitisers offer a quick and convenient method for sanitation whereby hand washing may not be possible. Ethanol is often the key ingredient in a hand sanitiser. Ethanol has a low viscosity and low evaporation point, which makes it difficult to handle – either dripping away and getting wasted, or evaporating before it can fully coat the surface of the hands.

Hand sanitisers offer a quick and convenient method for sanitation whereby hand washing may not be possible. Ethanol is often the key ingredient in a hand sanitiser. Ethanol has a low viscosity and low evaporation point, which makes it difficult to handle – either dripping away and getting wasted, or evaporating before it can fully coat the surface of the hands.

Rheology modifiers and gelling agents are added to provide several key benefits:

- Prevent dripping and waste of the product during use

- Keep the alcohol around long enough that it can coat as much skin as possible

- Give the product substance so it can be handled and manipulated

Hand sanitiser rheology modifiers range from carbomers, cellulose, polyquaterniums and acrylates or copolymers. It can be challenging to avoid some unintended and undesirable side effects from their use. Common challenges include pumpability/dispensing issues, controlling how long the hand sanitiser takes to evaporate, a sticky after-feel, residue or stability. In some cases it may be desirable to suspend ‘beads’ for a visual or texture effect. These challenges can all be investigated using in-vitro physical testing techniques.

The best metrics to use when characterising hand sanitisers, starting with viscosity

Viscosity is often the first port of call when trying to measure the physical properties of liquids and semi-solids. We’ve explained the importance of viscosity to hand sanitisers in another article which you can read by clicking on this link.

Viscosity is often the first port of call when trying to measure the physical properties of liquids and semi-solids. We’ve explained the importance of viscosity to hand sanitisers in another article which you can read by clicking on this link.

However, viscosity alone is insufficient to fully describe the handling behaviours of non-Newtonian products, such as hand sanitisers. Yield stress, modulus, extensional properties and lubrication all contribute to the haptic perception of a hand sanitiser. These additional metrics must be considered in addition to viscosity to better understand handling behaviour.

Yield stress can prevent dispensing and evacuation, but gives hand sanitisers ‘body’ and ‘structure’

The yield stress of a material is the stress at which significant flow is achieved. Yield plays a part in preventing hand sanitisers from dripping but also creates a challenge by making a product more challenging to pump. A high yield stress means that a product keeps hold of its shape, and may not readily collapse when adhered to the side of a bottle. Ideally you want a high enough yield stress to achieve the perception of a thick, yet spreadable gel but have it low enough that it does not interfere with dispensing.

The yield stress of a material is the stress at which significant flow is achieved. Yield plays a part in preventing hand sanitisers from dripping but also creates a challenge by making a product more challenging to pump. A high yield stress means that a product keeps hold of its shape, and may not readily collapse when adhered to the side of a bottle. Ideally you want a high enough yield stress to achieve the perception of a thick, yet spreadable gel but have it low enough that it does not interfere with dispensing.

Extensional resistance manifests as stringiness but helps create a lubricating film

Surfactant solutions or products containing high molecular weight linear polymers can be drawn into long filaments will often resist extension and form long filaments when ejected from an orifice. Often seemingly low viscosity formulations can fail at the pumping stage due to excessive viscoelastic behaviour. A product with high extensional resistance will act to keep the bulk of the product as a single mass – which can be useful for designing a product that creates a thin film.

Surfactant solutions or products containing high molecular weight linear polymers can be drawn into long filaments will often resist extension and form long filaments when ejected from an orifice. Often seemingly low viscosity formulations can fail at the pumping stage due to excessive viscoelastic behaviour. A product with high extensional resistance will act to keep the bulk of the product as a single mass – which can be useful for designing a product that creates a thin film.

Slipperiness, sliminess and other lubrication qualities.

In continuous spreading, the applied layer of product becomes thinner until the applying surface contacts the coating surface. Tribological measurements are more useful to describe this thin film lubrication behaviour and can help benchmark the slipperiness of a hand sanitiser. A tribological fingerprint can be useful in identifying the mode of lubrication relevant to late-stage spreading.

Stickiness and tackiness on drying

Stickiness and tack are undesirable characteristics for a hand sanitiser leading to discomfort, and unpleasant attachment of dust and other small particles to newly sanitised hands. Stickiness is often due to residue left behind from the sanitiser evaporating. We can measure stickiness and tackiness enabling objective and quantified comparison of this property.

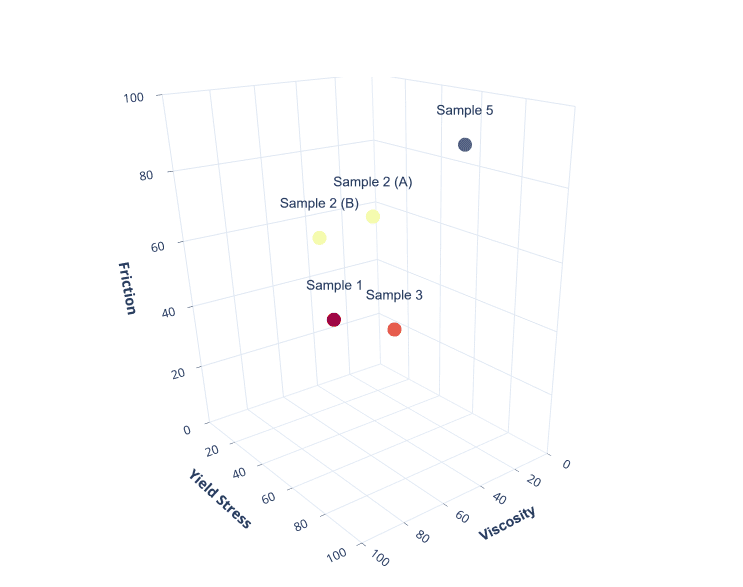

Considering the sum of parts

Physical behaviour of soft materials is often not accurately described with a single metric. It can also be difficult to identify the significance of any one given measurement on the observed phenomena. Our decades of experience working with pharmaceuticals, medical devices and cosmetics means we can quickly assist data interpretation and provide you and your team with the insights necessary to make business vital decisions.