We provide a range of sample analysis, test method development and training services for companies that formulate dermal fillers, OVDs, lubricating eye drops and visco-supplementation products.

The rheology of hyaluronic acid is crucial to its performance in its many applications:

The rheology of dermal fillers is critical, with properties such as rigidity (elastic modulus and viscous modulus), zero-shear viscosity, viscoelastic “relaxability”, cohesivity and viscosity under shear all contributing to their handling, injection, volumizing and residence time.

In ophthalmic viscosurgical gels (OVDs) the rheology determines whether the gel exhibits “dispersive” on “cohesive” characteristics, offering surface protection and film-forming or rigid structuring in use, and easy aspiration upon completion of a surgical procedure.

Ophthalmic lubricants incorporate hyaluronic acid for its excellent lubrication, where the combination of high zero-shear viscosity, low high shear viscosity and viscoleastic behaviour ensure a comfortable cushion of liquid sits between the eyelid and cornea.

In viscosupplementation applications hyaluronic acid’s rheology imbues it with lubricating and film-forming qualities and its viscoelastic responses to the imposition of sudden or maintained stresses.

Get a quote for sample analysis or training and advice

The viscoelastic properties of hyaluronic acid

One of the key attractions of hyaluronic acid for biomedical applications is its viscoelasticity: the ability to demonstrate solid-like (elastic) behaviour under some circumstances and liquid-like (viscous) behaviour under others. Viscoelasticity manifests as two critical attributes in HA products: Timescale dependant viscoelasticity and cushioning.

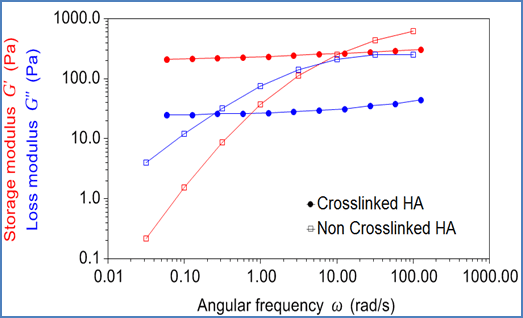

The figure below shows the results of oscillatory frequency sweeps on crosslinked and uncrosslinked HA formulations.

Both products demonstrate elastic-dominance at high oscillation frequencies: G’, the storage modulus is higher than G”, the loss modulus and phase angle is, therefore low (phase angle = arctan G”/G’). “Elastic-dominant” simply means “more-solid than liquid”, the material bounces like jello rather than flows likes honey. However, the uncrosslinked product, typical of an ophthalmic viscosurgical gel or a viscosupplementation injectable, shows a clear trend to a viscous behaviour as the oscillatory frequency decreases (that is, as the timescale of deformation lengthens), whereas the crosslinked product, typical of a dermal filler, maintains a solid like behaviour even down at very low frequencies . The strong timescale dependence seen in the uncrosslinked product enables the product to move easily but provide cushioning and protection against impacts.

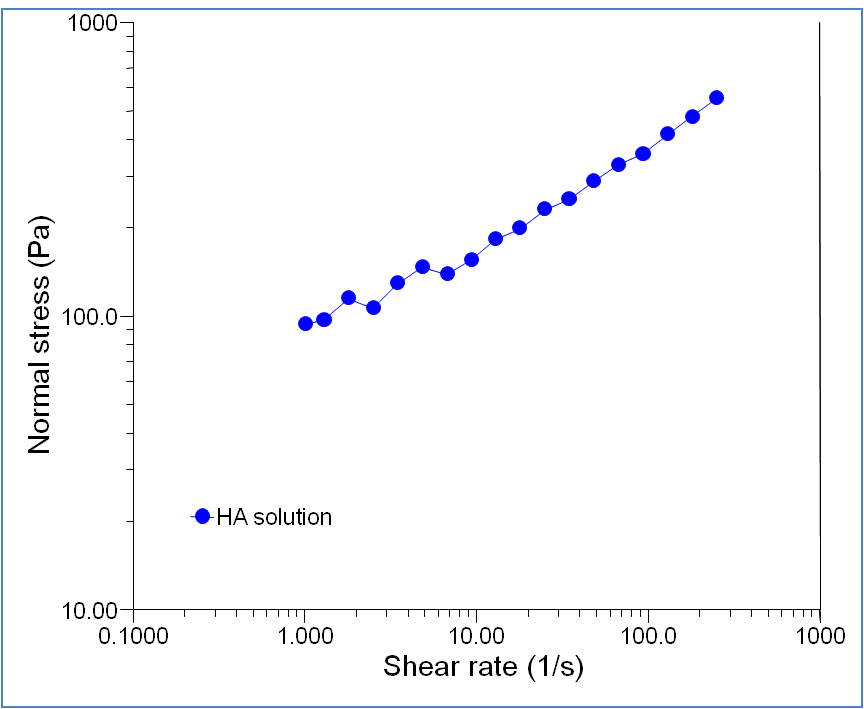

Normal stress measurement and film-forming ability

From a shear rate profile a measurement of a useful property, normal stress generation under shear, can be obtained. Normal stress is a stress generated perpendicular to the direction of shear when an elastic fluid is sheared. The magnitude of normal stress generated often correlates well with the ability of a polymeric solution or gel to film-form. Film-forming ability is a pre-requisite for thick-film lubrication. On a research rheometer normal stress is measured using a force transducer fitted below the measuring plate. An example of the normal stress growth observed with hyaluronic acid is shown below in figure 2:

Measuring the viscosity of hyaluronic acid

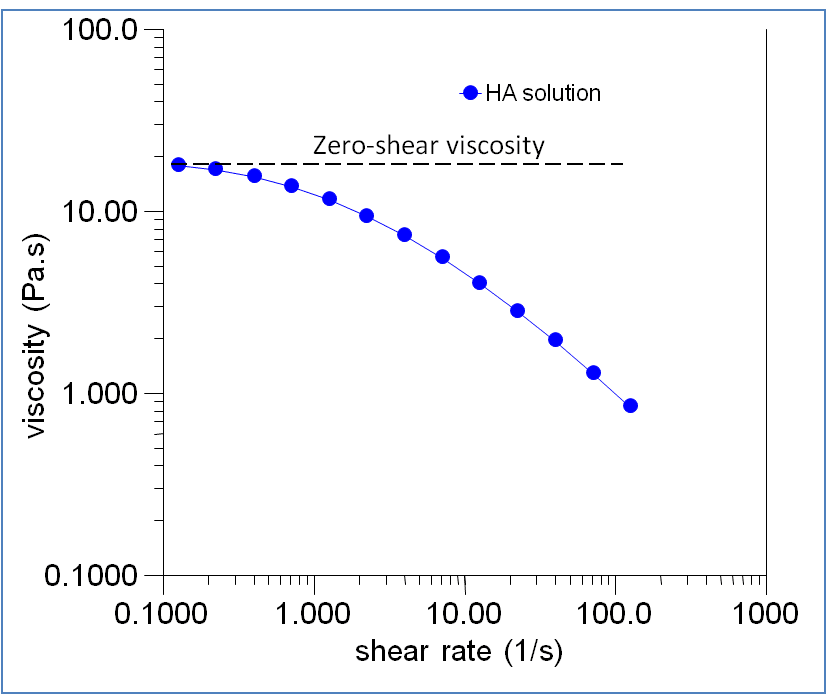

As a polymer in solution, hyaluronic acid shows non-Newtonian viscosity behaviour. Non-Newtonian liquids exhibit viscosity dependence upon the applied shear conditions, the most common type of non-Newtonian behaviour being shear-thinning, where viscosity decreases with increasing shear rate. This characteristic is beneficial as it allows for the product to be moved around and managed with greater ease, such as when pumped and filled in manufacturing processes, spread on the skin by a consumer or injected by a surgeon, but once at rest the product regains its viscosity, helping maintain its position.

While this characteristic is very desirable, it creates problems when attempting to measure the viscosity of hyaluronic acid solutions and gels. A single-point viscosity test such as that typically conducted on a simple viscometer is insufficient to fully characterize the material. Instead of this, a viscosity/shear rate profile (such as that shown in figure 1) is more suitable as a means of measuring this material.

Shear thinning behaviour is clearly demonstrated within the results, with viscosity decreasing by a factor of over 20 times as the shear rate was increased. Interestingly, the sample demonstrated a Newtonian plateau at low shear rates. This plateau viscosity, known as a zero-shear viscosity, is a useful and important material attribute as this signifies the viscosity in an effectively at-rest condition. The magnitude of zero-shear viscosity and extent of the low-shear section of the curve are influenced by both molecular weight and weight distribution and hence can provide an indirect assessment of these factors for batch screening purposes.

If you would like any further information or have any questions regarding the rheological profiling of hyaluronic acid, please contact us.