A lithium-ion battery is generally composed of two electrodes that are spatially separated, a separator between the electrode (usually a microporous membrane), and an electrolyte. The electrode contains a solid matrix that contains an active material, additives for conductivity improvement (often carbon black) and a binder.

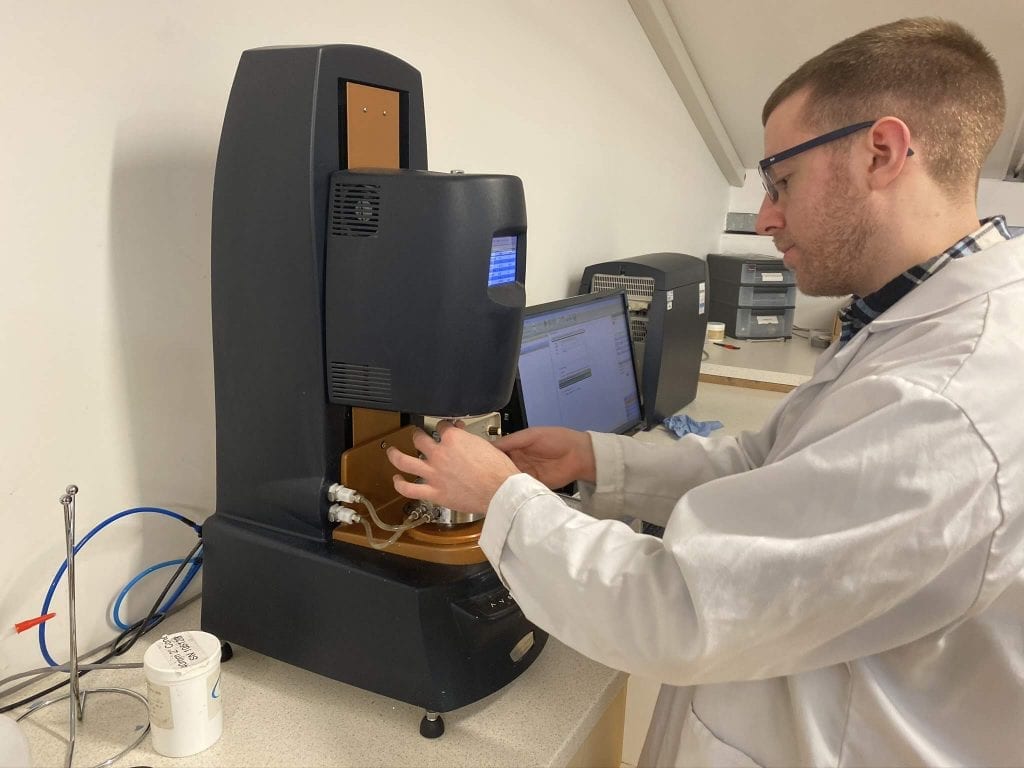

The solid matrix in the electrode is usually applied as a slurry, which is a mixture of heavy solid particles in suspension. The need to extensively process this material and apply it as a thin coating, often in layers, requires a specific rheological profile. Viscosity and shear thinning properties help with mixing, yield stress and zero-shear viscosity aid with stability. A whole host of rheological properties such as surface tension and extensional viscosity, as well as viscosity and yield stress, come into play when using slurries as a thin film electrode coating and have a significant impact on battery performance.

Contact us to discuss approaches for characterising your battery electrode slurries.

The Rheology of an Electrode Slurry is Intrinsically Tied to It’s Handling Properties

Electrode slurries are a mix of solid, conductive particles along with active materials, polymer binders and a solvent medium. The performance of the cell is highly dependent upon the electrochemical properties of the active materials as well as the distribution of the components within the electrode slurry, the connectivity between the components and the adhesion of the electrode with the current collector.

Preparation of the slurry

Generally speaking, the slurry is prepared by mixing any solid components, wetting the mixture with an appropriate solvent and finally forming the suspension, which has to be degassed before use to remove gas voids and avoid coating defects. Once prepared, the slurry film is applied to the substrate and dried by evaporation.

During mixing of the solids, it is widely accepted that deagglomeration of carbon black leads to more homogenous mixing and increased carbon black adsorption onto the surface of the active material. Wetting the solid mixture by adding solvent in differing quantities can lead to different states of adhesion and stress, as well as agglomeration of solid particles; these properties can be monitored using powder flow rheology.

Wetting solvent and dilution effects

Changing the wetting solvent and diluting to different concentrations can lead to significant rheological differences in slurry behaviour. For example, having a highly viscous medium for an electrode slurry can impart many benefits to stability, storage and application. It has been noted that gradual dilution of a dense slurry can give a better dispersion state and battery performance, but excessive dispersion can lead to a deterioration in performance. This is suggested to be due to destruction of electrical conductivity paths.

Viscosity

Viscosity can be a complication during mixing, however, as it can be difficult to achieve a uniform dispersion with higher viscosity solutions, which can affect battery performance. For example, the capacity, energy, electrical conductivity and mechanical integrity of the electrode could all be compromised. The use of plasticisers has allowed control of viscosity to some extent, but by profiling the bulk rheology of benchmark formulations, chemists can target specific rheological characteristics and ensure their electrode slurry mixes, disperses and stores as well as expected from a modern, high-quality product.

In addition many materials, including electrode slurries, are shear thinning materials; i.e. the material reduces its viscosity under shear. Fortunately, shear thinning can be an incredibly useful property for an electrode slurry. As force is applied to the mixture, the viscosity lowers and the particles are free to disperse evenly throughout, resulting in a homogenous mixture. Once mixing has concluded, the viscosity of the mixture can increase again to aid in holding the particles in space, helping to maintain homogeneity.

Thixotropy

The time-dependent thickening of material after shearing has stopped is referred to as thixotropy. If the material does not thicken quickly enough, or fails to regain the original structure, the material may drip off the substrate (creep), may sag or slump at the surface, or there may be stringing or tailing from the application nozzle. All these phenomena could lead to reduction in the coating consistency and therefore quality of the electrode.

The Slurry Itself is Rheologically Demanding

This combination of heavy, solid particles in a liquid medium makes handling, processing, and storage of electrode slurries a particularly difficult task. The ideal slurry must:

- Have a low enough viscosity to be mixed well, but a high enough viscosity to slow the settling of solids and maintain homogeneity.

- Yield well during mixing and create a homogenous mixture, but once mixed needs to resist yielding to hold those particles in place.

- Level well to create a thin, even film layer when coated onto the electrode. In addition it needs to maintain that levelling while drying to ensure necessary conductivity. This is particularly important for active materials with low conductivity e.g. LiFePO4.

- Have good adhesion between the electrode coating and current collector with low resistance to the transfer of electrons across the interface between the electrode and current collector.

Storage – Viscosity, Shear Thinning and Yield Stress

Once the mixing is completed and an even dispersion has been achieved, maintaining that dispersion during storage is a separate challenge. Even if the electrode slurry is stored under strict conditions, the dispersion state of the slurry can deteriorate due to agglomeration of particles or reconstruction of microstructure by agitation. This may cause problems during application including surface defects, non-uniform thickness or non-uniform electrode loading, and clogging of pipes and filters. Once again, there are rheological properties that can be targeted within a formulation to aid with stability and maintain an even particle dispersion.

Zero-shear viscosity describes the viscosity of the slurry at rest, such as when it is in storage. While a slurry can display obvious fluid properties, at very low stresses it has the potential to react as a solid. The zero-shear viscosity can aid with stability, preventing the solid particles from settling to the bottom of the solution.

The yield stress of the slurry is the amount of force needed to elicit significant flow. On a large scale, yield stress can be a valuable measurement to aid application and defect reduction. On a micro-scale, however, yield stress can be incredibly valuable property to aid with stability. The weight of the solid particles needs to overcome the yield stress of the liquid part of the slurry in order to fall to the bottom. If the yield stress is high enough, the particles are unable to fall, and will not be able to sediment out.

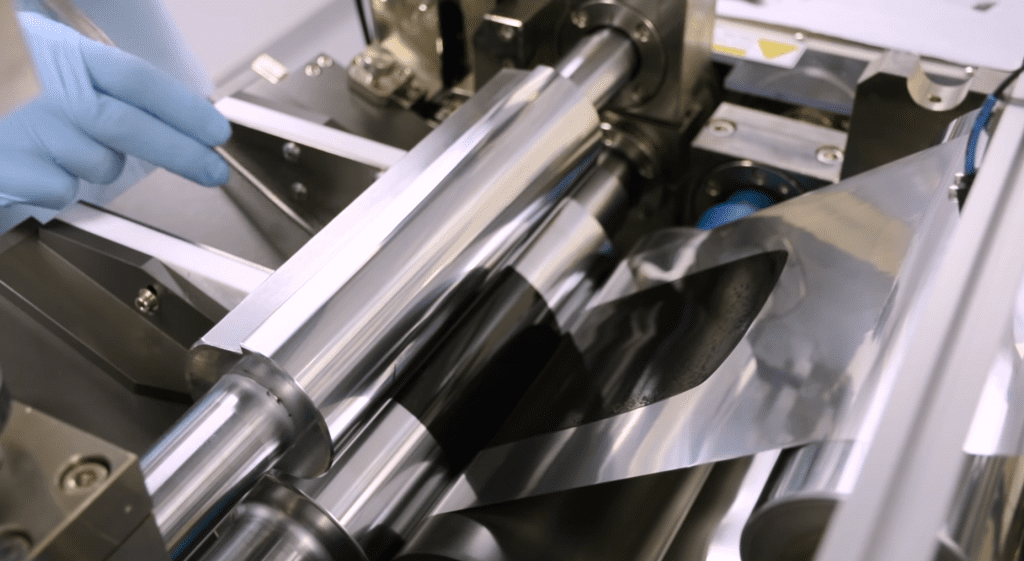

Rheology is Key to Creating Even Layer Thin Films In Any Printing Process

The rheology of coating and coating defects is an expansive area – we have written about it before (read about it here). In a battery slurry, these defects can be hugely detrimental to the final performance of the electrode. The slurry must level well and dry into a thin film without defects to ensure an even coating layer and contact area with the electrode. While the coating method selected to create this film will play a part in the minimisation of defects, rheology plays a vital part when selecting and tuning coating systems. Viscosity, zero-shear viscosity and yield stress play a part here, as do other factors such as cure time, extensional viscosity and interfacial rheology (surface tension and surface energy).

Conclusion

At all stages of an electrode slurry’s life there are a wide range of rheological properties that can be measured and controlled in order to elicit specific characteristics in the finished product. Mixing, storage, coating and drying are all processes that are affected by the slurry’s rheology. Viscosity, yield stress and shear thinning properties can aid with creating and maintaining homogenisation within the slurry. All those properties as well as interfacial rheology measurements such as surface tension play a part in the handling, coating and drying properties of the slurry, affecting how it spreads, levels and forms a film. A combination of all these rheological factors can be vital for understanding and improving key handling properties of your electrode slurry as well as improving battery performance.

Should you wish to discuss testing of your own battery electrode slurries please feel welcome to contact us.