Screen printing is a popular method for depositing conductive or resistive inks or pastes for the manufacture of printed electronics. The rheology of screen printing materials, including shear thinning behaviour, thixotropy and the presence of a yield stress, are key to the speed and efficiency of a process. Understanding these rheological properties is vital to formulating a screen printing ink, or optimising your screen printing process to work with any given ink or paste.

Contact us to discuss the characterisation of your screen printing inks

A screen printing ink is made up of a few different parts. Water or solvent-based, they can contain any number of solid particles (for example gold, silver or pigment) and binder chemicals. Along with these chemical elements, rheology modifiers are often added to aim for specific properties. With expensive elements such as gold or silver often included in screen-printed electronics, getting these properties right by trial and error can be a frustrating, and expensive task.

The Advantage of Rheological Profiling

With rheology we can create a profile for your ink or paste using relatively small sample sizes. By comparing the rheological profile of your ink to other formulations, or competitor benchmarks, you can get a headstart on your research & development and target specific vital properties. Rheological profiling can help you create better products and processes faster with a lower cost.

There are a number of properties that are ideal for screen printing inks. In general, screen-printing inks tend to be high viscosity, shear thinning, highly structured liquids with a quick thixotropic recovery rate. While that might sound like a bit of a mouthful, all of those factors are observable – and measurable – and vital when designing a screen printing ink or paste.

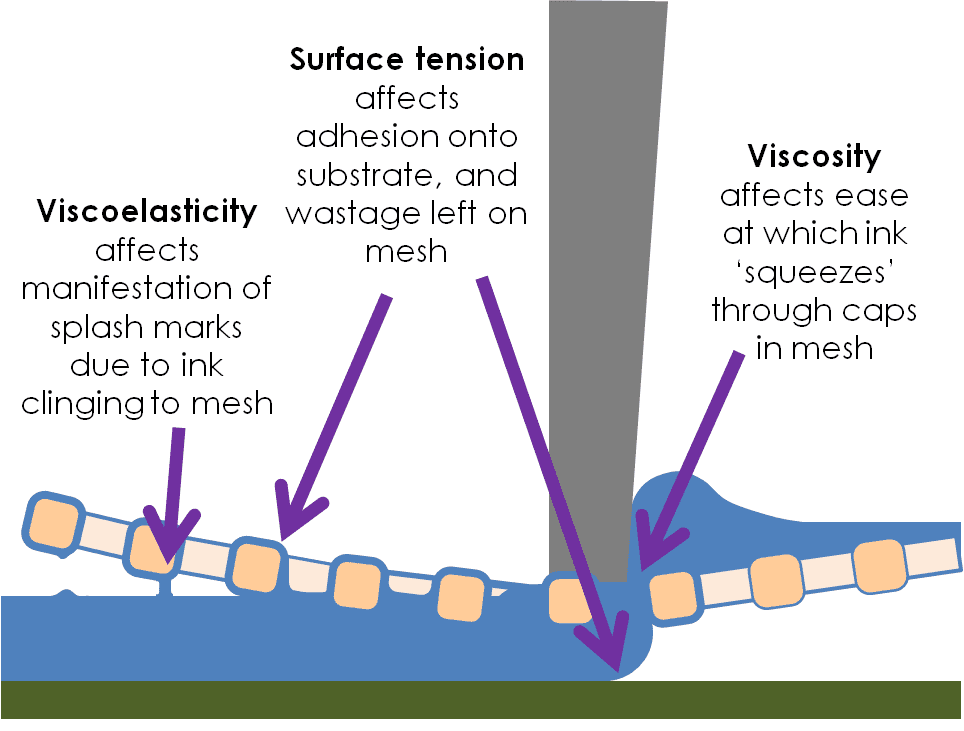

Viscosity

High shear forces applied to the ink as it is squeezed through the mesh can change its physical microstructure. Often, this results in shear thinning, where the viscosity of the ink lowering as force is applied to it. This can mean the ink you take out of the pot is not the same as the ink that reaches your substrate. A small amount of shear thinning is ideal, too much can lead to your ink spreading or creeping once deposited. Viscosity at very low shear rates, lower than can be measured on traditional viscometers, can be measured by very gently probing the ink. This “Zero Shear Viscosity” can be a vital parameter to assess ink stability.

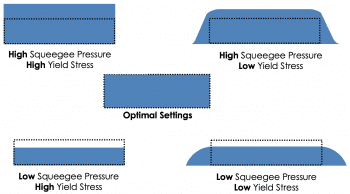

Yield Stress

The yield stress of a material refers to the pressure needed to elicit significant flow. In terms of screen-printing inks, the yield value can elicit useful information for planning your squeegee pressure. Your squeegee will need to overcome the yield value of the structured screen-printing ink, pushing it through the mesh. Excess squeegee pressure past this yield value can lead to more ink than necessary being deposited onto the surface – increasing the cost of your process in lost materials and reprints. Yield stress can also be important when looking at ink stability, particularly in dispersions with solid particles like pigments or metals.

The yield stress of a material refers to the pressure needed to elicit significant flow. In terms of screen-printing inks, the yield value can elicit useful information for planning your squeegee pressure. Your squeegee will need to overcome the yield value of the structured screen-printing ink, pushing it through the mesh. Excess squeegee pressure past this yield value can lead to more ink than necessary being deposited onto the surface – increasing the cost of your process in lost materials and reprints. Yield stress can also be important when looking at ink stability, particularly in dispersions with solid particles like pigments or metals.

Thixotropic Recovery Rate

Applying a shear force to a liquid, such as forcing it through a screen-printing mesh, can cause changes to its chemical structure. The speed at which the liquid returns to its at-rest structure is described as the thixotropic recovery rate. Ideally, a screen printing ink has an incredibly fast, almost instant, thixotropic recovery rate. This means the ink passes seamlessly through the mesh, and once deposited, stays where it is. Particularly in printed electronics, where the spaces between coated areas can be in the order of microns, even a small delay in the recovery of the coating can cause misprints – leading to short circuits, reprints and wasted materials.

Thermorheology

All of the above properties have the ability to change depending on temperature. The operating temperature of your process can be tweaked to bring the best properties out of your ink. As the machinery starts working, and the squeegee starts applying friction into the process, things heat up. Rheological testing can be carried out while cycling temperature in order to assess the properties of your screen printing paste across the range of temperatures.

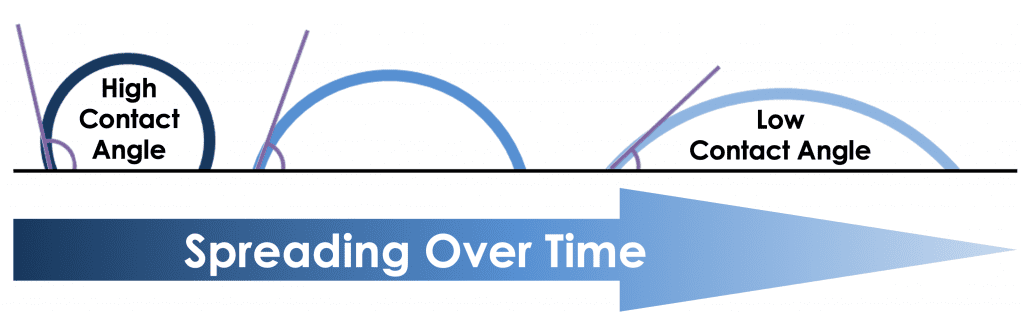

Interfacial Rheology

Once deposited to the substrate, a screen printed coating can be in the order of 30-40 microns. At this point, surface tension and surface energy becomes vital to understanding the wetting and spreading properties of the ink. By measuring advancing contact angle, receding contact angle and surface energy you can predict the behaviour of very thin coating films once applied to the substrate.

Conclusion

Whether formulating a screen printing ink or setting up a screen print, rheological measurements can be key to achieving fast print speeds while maintaining precision. The viscosity, yield stress and surface tension measurements of your ink can be measured and designed to create an ink which passes through a mesh, leaves an even layer of defined thickness and resists spreading once deposited. The thixotropy and thermorheological properties of the ink can allow you to improve the squeegee speed, pressure and angle in your process to work best with your ink.

If you would like to learn more about other approaches to characterising the physical properties of your screen printing materials, please feel welcome to organise a talk with us.