Viscosity is a vital measurement to consider when formulating hand sanitisers. Hand sanitisers offer a practical and convenient alternative to finding hand washing stations, and typically come in the form of gels. This is to ensure that the disinfectant in the gel can cover as much of the surface of the hand before evaporating away with little mess or residue. Thin gels are easy to handle, but might dribble away leaving mess or wasting product. Thick gels might slow the evaporation process too much, leaving the user with slimy hands for longer than necessary or even end up getting stuck in packaging. Accurate rheological measurements can be key to underpinning the physical characteristics that make for successful hand sanitising gels.

Viscosity is a vital measurement to consider when formulating hand sanitisers. Hand sanitisers offer a practical and convenient alternative to finding hand washing stations, and typically come in the form of gels. This is to ensure that the disinfectant in the gel can cover as much of the surface of the hand before evaporating away with little mess or residue. Thin gels are easy to handle, but might dribble away leaving mess or wasting product. Thick gels might slow the evaporation process too much, leaving the user with slimy hands for longer than necessary or even end up getting stuck in packaging. Accurate rheological measurements can be key to underpinning the physical characteristics that make for successful hand sanitising gels.

We can provide rapid viscosity testing of hand sanitisers, contact us to discuss your requirements.

Viscosity is often at the forefront of the design, formulation and manufacturing process for a hand gel, whether or not that be a conscious choice. Often thought of simply as “thickness”, viscosity plays a significant role in a range of situations that a hand sanitizer experiences. From pumping, mixing and handling, to storage, all the way through to quality assurance, customer perception and end use feel of the gel. Measuring and targeting specific handling properties and behaviours during formulation is key to getting all of these aspects of your hand gel right and creating an excellent product.

The Importance of Viscosity

A higher viscosity product may be perceived as higher quality to your end user than a sanitiser which dribbles away but may prove difficult to process in bulk. A low viscosity can allow for packaging needs, for example allowing the gel to be pumped straight from the bottle. How do you formulate a product that leads a double life depending on how you interact with it?

Non-Newtonian Behaviour: The Key to Pumping and Processability

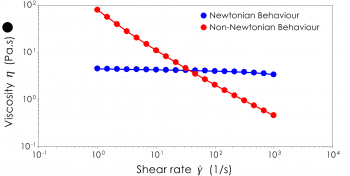

The other key factor that can alter the viscosity of a formulation is applied shear. A Non-Newtonian fluid works such that it’s viscosity changes based on the shear rate applied to it. This key property – fairly common amongst hand gel sanitisers, can allow for different handling behaviours dependent on the situation. A high viscosity at storage makes a product look high quality; a drop in viscosity when sheared allows the gel to be dispensed through a pump or nozzle while maintaining a quality feel.

Potential Influencing Factors

Alcohol percentage, salt content and pH are all likely to affect your choice of polymer. The choice of polymer will likely be a key determinant for the viscosity of your formulation. Many factors which may not be immediately obvious may also play a part in the final viscosity of your product. Fragrance, for example, added even in small amounts poses the potential to change the handling behaviour of your gel in unexpected ways. Polymer hydration during manufacture can cause a viscosity build overtime, meaning that this value can be different depending on when you test your sample. Popular hand sanitisers not only pay attention to the ability to disinfect, but also how a customer might use and perceive the product.

Alcohol percentage, salt content and pH are all likely to affect your choice of polymer. The choice of polymer will likely be a key determinant for the viscosity of your formulation. Many factors which may not be immediately obvious may also play a part in the final viscosity of your product. Fragrance, for example, added even in small amounts poses the potential to change the handling behaviour of your gel in unexpected ways. Polymer hydration during manufacture can cause a viscosity build overtime, meaning that this value can be different depending on when you test your sample. Popular hand sanitisers not only pay attention to the ability to disinfect, but also how a customer might use and perceive the product.

Viscosity: Not Just a Number

The viscosity of a product can change as a result of numerous factors; temperature, humidity and conditioning all play a part. A product that behaves perfectly in the laboratory may come out of an elevated temperature processing line at a completely different viscosity. A Carbopol based product which thins down in contact with salt on the skin may not retain this feature if the Carbopol is replaced with a green eco-friendly alternative.

Fortunately, formulators have a range of options available in order to target key viscosity values in their products. Accurate viscosity measurements with rapid turnaround times enable fast and efficient formulation, reformulation and even competitor benchmarking to target key viscosity values and ultimately create a high quality, effective product.

Conclusion

Viscosity plays a part in many key aspects of a hand sanitiser gel’s functionality. Processing, performance and customer perception are all heavily linked to viscosity values. Understanding viscosity and being able to rapidly take accurate and meaningful viscosity measurements is key to understanding your hand sanitiser from formulation in the lab to use on the skin. Generating accurate viscosity data over a range of temperatures, humidities and shear rates allows you to compare your formulations against each other, and to market leaders, in order to create the high-quality products that your customers expect.

Viscosity plays a part in many key aspects of a hand sanitiser gel’s functionality. Processing, performance and customer perception are all heavily linked to viscosity values. Understanding viscosity and being able to rapidly take accurate and meaningful viscosity measurements is key to understanding your hand sanitiser from formulation in the lab to use on the skin. Generating accurate viscosity data over a range of temperatures, humidities and shear rates allows you to compare your formulations against each other, and to market leaders, in order to create the high-quality products that your customers expect.