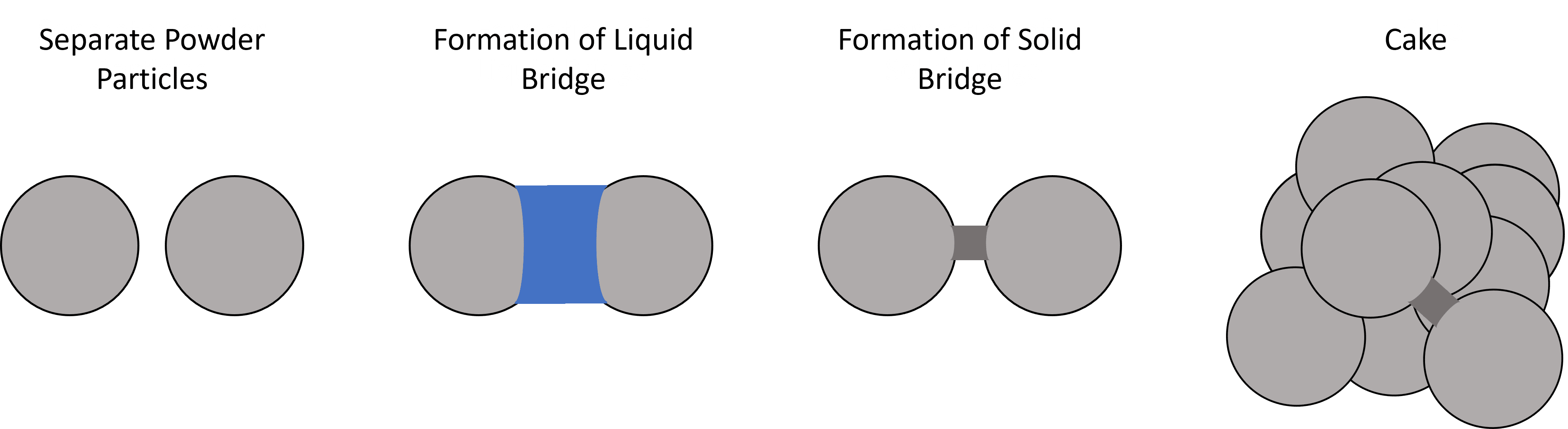

Powder caking is a universally experienced phenomenon with the potential to ruin production runs and grind factories to a halt. A robust caking study can provide early indicators of a powder’s propensity to cake, identifying major contributing factors to the phenomenon and potentially indicating working times for powders before the onset of significant caking.

Instrumentation and Methodology

At the Centre for Industrial Rheology we utilise a dynamic powder flowability test for our caking measurements. A blade is moved in a helical pattern through a column of powder, and the energy required to maintain the set blade speed is measured. The more energy required to maintain speed, the less flowable the powder.

We have two setups capable of running these dynamic powder measurements: a Freeman FT4 Powder Rheometer, and a Powder Flow Cell Kit for the TA HR Series Rheometers. The methods and measurements are however easily translatable to any equivalent powder rheometer you may have in house and can also oftentimes be adapted to work for other instruments.

Arrange a meeting with one of our specialists today

How do we induce caking? Sample conditioning

Once a “benchmark” measurement is made of the pre-caked powder, a second measurement is performed on a fresh aliquot of powder subjected to a “caking step”. This caking step usually involves subjecting the powder to a period of elevated temperature, humidity, consolidation force, or any combination of the three.

Caking steps can be as simple or as complex as is required, ranging from elevated humidity for a number of hours followed by a drying step at atmospheric conditions to multi-day, multi-step conditioning cycles. We always work with our customers to ensure that the caking step performed on their samples is suitable for their powders, relevant the situations they are likely to encounter, and optimal for producing repeatable, reliable data.

Importantly, the powder is conditioned in the test vessel, so no disturbance is required between the caking step and the initial testing step.

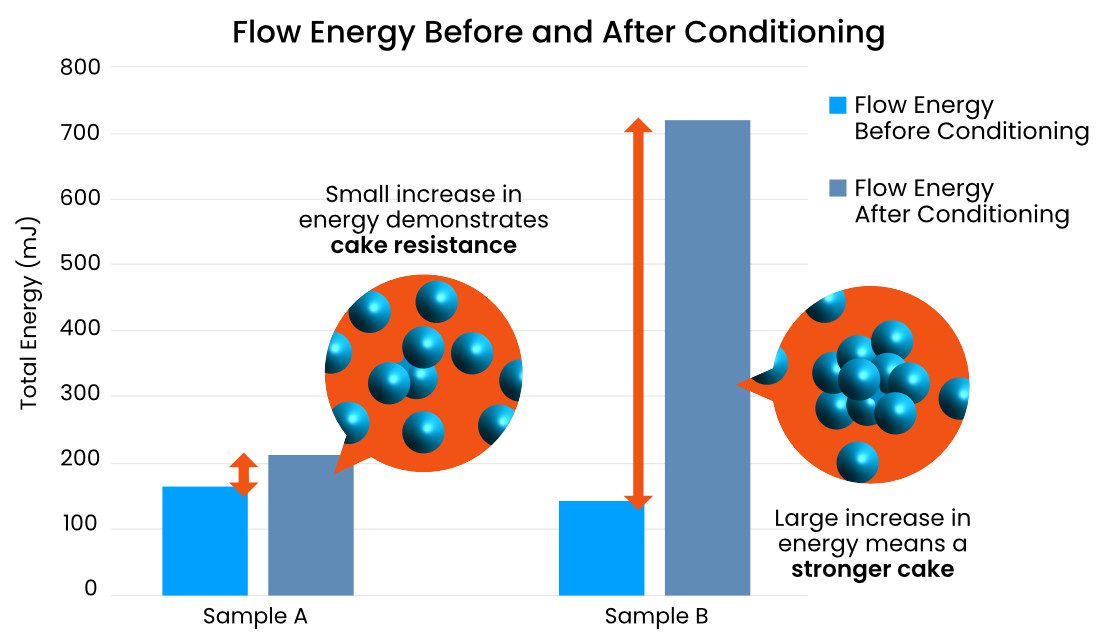

Flow energy measurements to assess caking severity

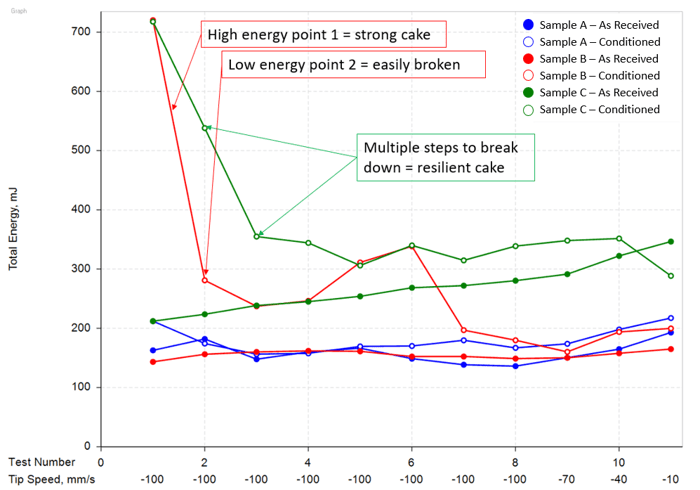

By analysing changes in flowability in terms of ‘flow energy’ we are able to generate a rapid measurement of the degree to which a powder has caked. A large increase in flow energy indicates that a powder has caked.

Understanding cake breakdown

By performing multiple tests on a caked sample and comparing the resulting curve to the same, un-caked sample, we are able to generate insight into the ease at which a cake is broken down. Does the cake break down immediately and fully when manually handled or does it take multiple cycles to break through remaining agglomerates? Does the powder ever return to it’s original flowability, or has a permanent change been enacted within the powder as a result of caking?

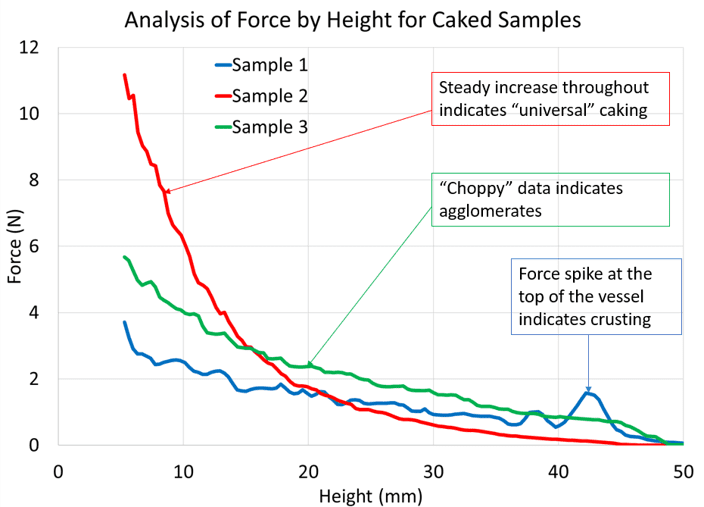

Force data as function of height to determine crusting or agglomeration

By examining the force as a function of height we are able to begin to make assessments about the type of cake that has been formed. A steady increase in force throughout the height of the vessel indicates a powder has caked evenly throughout the bulk. A pronounced force spike at the top of the vessel indicates crusting, while choppy force data is often indicative of agglomeration.