Do you put the jam on the cream or the cream on the jam? The perennial question. Let’s put this to the rheological test…

Cornish clotted cream and strawberry jam were purchased from Marks and Spencer. Viscosity, complex modulus and phase angle were determined for both components at 10 °C.

- Viscosity shows how the ‘thickness’ of the jam and cream vary in relation to each other.

- An oscillatory test determines the complex modulus, which will reveal the rigidity of both the jam and cream.

- Yield stress can be derived from the same oscillatory experiment and can be used as an indicator of spreadability.

- A thixotropic study shows how the viscosity of the cream recovers following cessation of shearing.

Contact us to arrange a lab tour and discuss rheological techniques with our experts

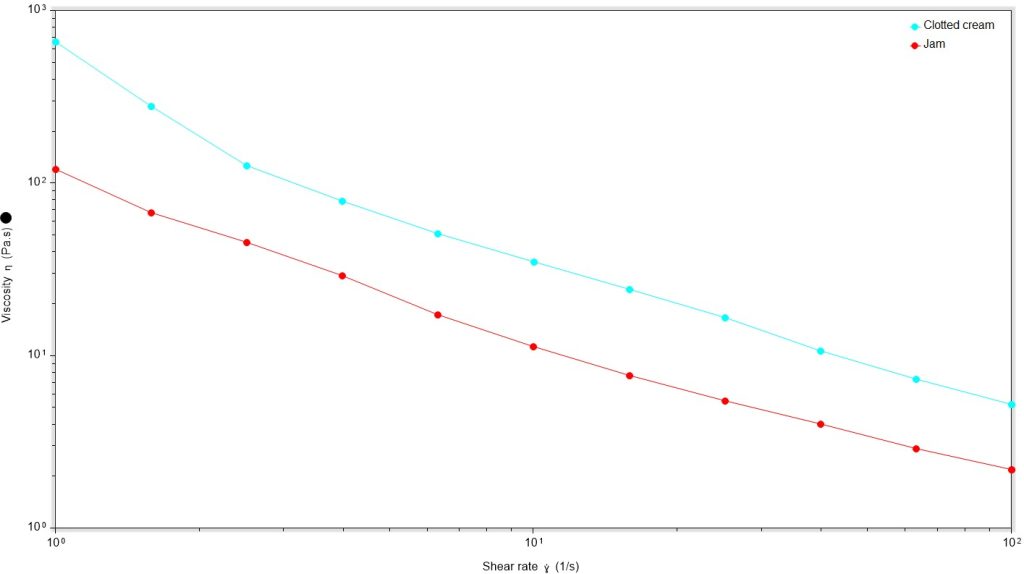

Viscosity

Both jam and clotted cream can be described as non-Newtonian, shear-thinning materials, Figure 1.

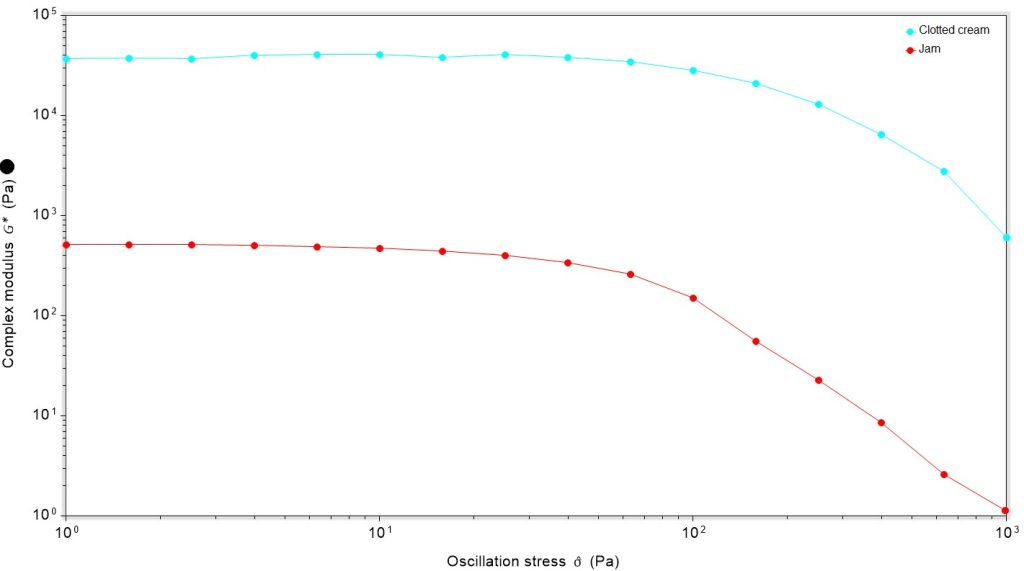

Complex modulus and yield stress

Clotted cream has a higher complex modulus than jam, indicating that it has a more rigid structure, Figure 2.

During this test the sample is oscillated. As the oscillation rate of the sample is increased, the complex modulus of both jam and clotted cream remain constant until the yield stress is reached, indicated by a large drop in complex modulus value; at this point the material begins to flow significantly. In the real-world, this is the stress that would need to be applied to spread the material; for clotted cream is 110 Pa and jam 56 Pa, so clotted cream requires more force to induce movement.

In addition, the yield stress can also be linked to the so-called spoonability of the product. A lower yield stress indicates that a material requires less effort to pick-up from a tub, for example when loading the cream or jam onto a knife. In this case, jam has easier ‘spoonability’.

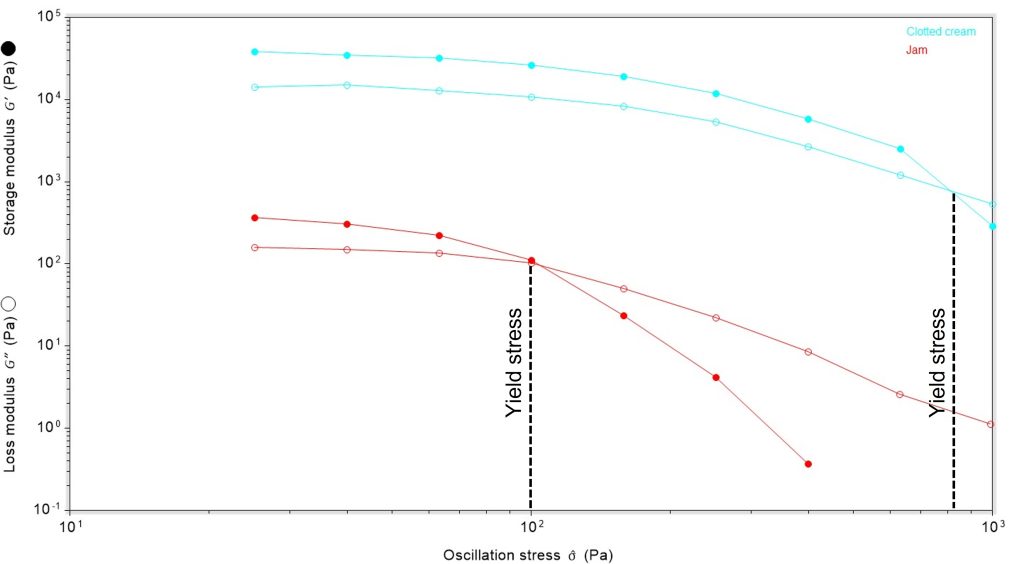

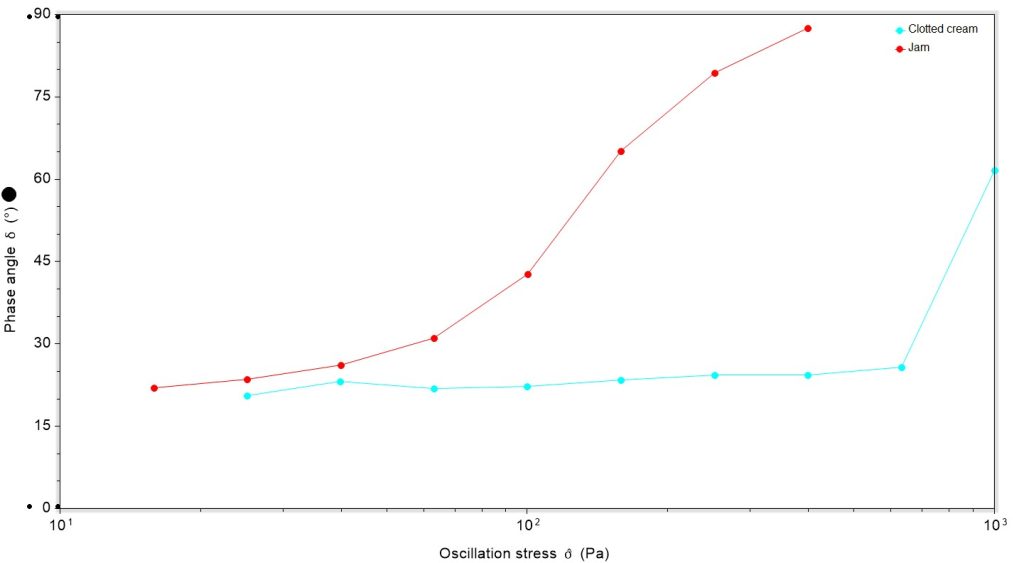

Phase angle and modulus cross-over

Under low oscillation stress both clotted cream and jam show solid-dominant behaviour, evidenced by the storage modulus being larger than the loss modulus. As oscillation stress is increased the behaviour tends towards liquid-dominance, shown by the storage modulus crossing the loss modulus. The point at which the moduli cross is known as the yield stress and is the point at which the stress applied to the material results in a catastrophic break-up of the structure, Figure 3. Jam switches to liquid-dominance at a lower oscillation stress than clotted cream showing that to induce jam spreading, less stress is required.

The onset of solid or liquid dominance can also be shown by the phase angle. A phase angle of less than 45°, at any given stress, denotes solid-dominant behaviour and over 45° liquid-dominant behaviour. The oscillation stress at 45° can also be used to give a yield stress value. The advantage of using a phase angle plot rather than storage/loss modulus plot is that it is arguably easier to visualise the degree of solid/liquid behaviour using phase angle, Figure 4.

Thixotropic behaviour of cream

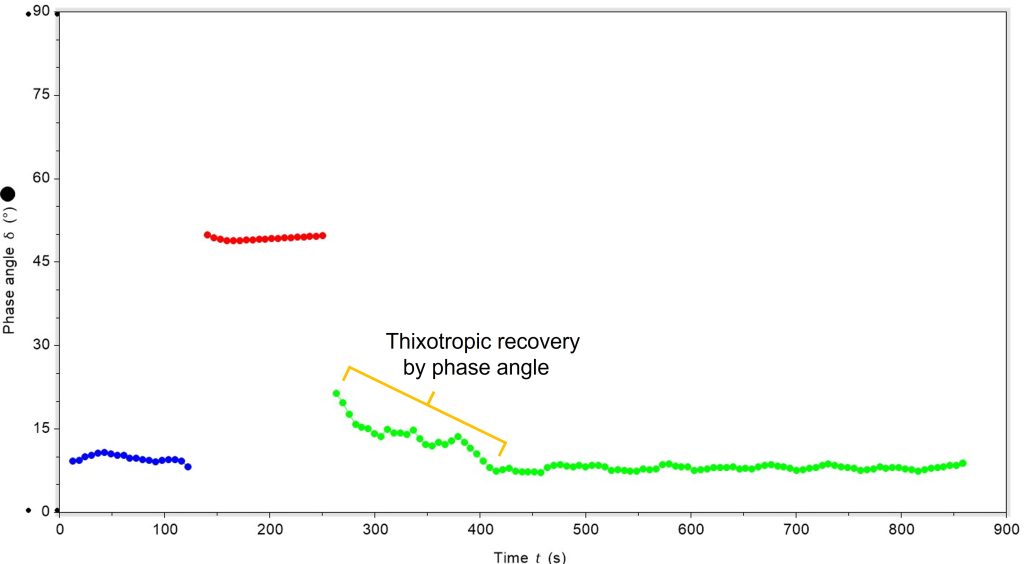

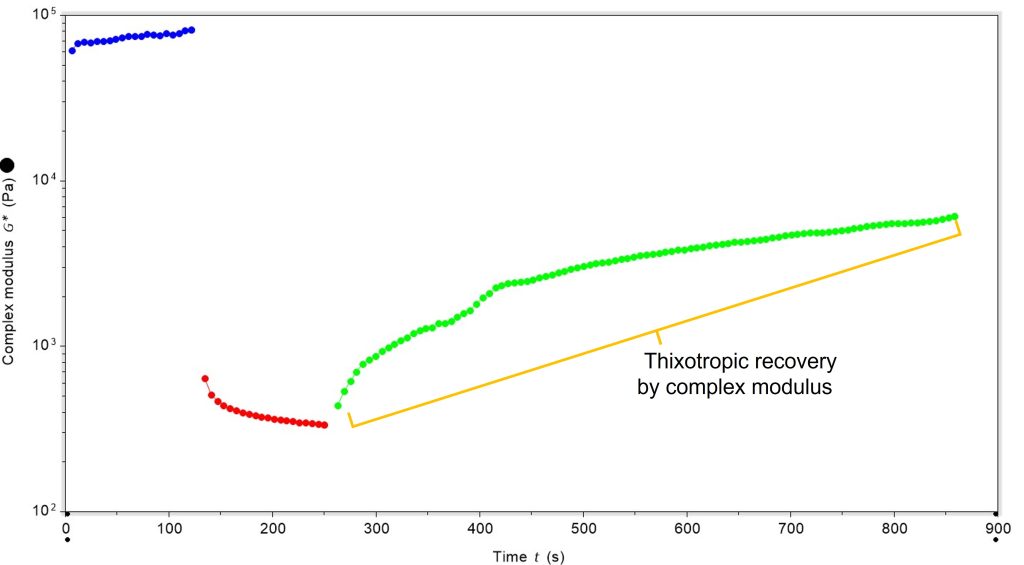

The final investigation was into the thixotropic behaviour of clotted cream. Thixotropy is the time-dependent viscosity change of a material. It is commonly used to show how quickly equilibrium viscosity can be recovered following a step-change in shear rate. A highly thixotropic material is one that takes a significant time to either thin to a low viscosity upon commencement of shearing or recover viscosity upon cessation of shearing.

The test involved oscillating the clotted cream at a strain within the linear viscoelastic (LVE) region (determined by oscillatory test), so the structure was maintained. The sample was then oscillated at a strain where the structure was destroyed (also determined by oscillatory test) and finally at the original, lower, strain. This allowed the phase angle and complex modulus to be determined, providing information in relation to solid/liquid-like behaviour dominance and rigidity, respectively.

Considering the phase angle, it could be seen that during the initial oscillation the material was solid-dominant and by increasing the oscillation strain the material changed to liquid-dominance. Upon slowing the oscillation strain, a clear transition back to the original solid-like material can be seen between 262 and 415 seconds, Figure 5.

Looking at the phase angle data in isolation, it seems like the clotted cream completely recovered from the increased oscillation strain and returned to a similar degree of solid-dominant behaviour fairly quickly. However, caution should be exercised and consideration of the complex modulus provides additional information, Figure 6. The data clearly show that complex modulus, or the degree of rigidity, was affected by the applied strain. After disruption of the structure by application of significant strain, it can clearly be seen that the complex modulus takes a long time to recover, and even after 10 minutes does not recover to the original value.

In layman’s terms, this means that although the cream recovered to a solid-like structure fairly quickly after structural disruption, the rigidity of that structure did not fully recover, even after an extended period. This tallies with in-person observations, where any thick cream that is stirred takes a while to recover rigidity and viscosity.

Jam before cream or cream before jam?

Clotted cream is more viscous and has a higher complex modulus than jam at lower shear rates i.e. more effort is required to induce movement in the clotted cream. When considering thixotropy and the decrease in complex modulus due to strain, the clotted cream recovers such that the complex modulus (and therefore rigidity) is higher than that of jam within 6 seconds of spreading.

The only logical conclusion from this casual study is that to have a good, rigid, base for the jam the clotted cream needs to be applied to the scone first. When considering thixotropy and the decrease in cream rigidity due to spreading-induced strain it takes 6 seconds for the cream to recover to the same rigidity of jam, which is arguably shorter than the time that it would take to dip a knife into jam and spread it onto the scone. This means that even when thixotropy is taken into account, the clotted cream should still be applied first.