Viscosity alone is sadly lacking as a metric to quantify the handling, delivery and textural attributes of suspensions, emulsions and gels.

The reason for this is that many of the materials we manufacture and deliver to the market spend most of their lives acting, not as liquids, but as soft solids. Viscosity is, of course, a liquid property; rigidity and strength however, are solid properties, and far more representative and relevant a measure for many cases. Consider the following example:

A simple viscosity reading, taken under equivalent conditions (RVDV2+, spindle 6, 20 rpm) yielded viscosity values of 30000 cP for a mayonnaise, 31400 cP for syrup and 30700 cP for a carbomer-based hair gel. Yet the differences between the three products couldn’t be more obvious:

- The mayonnaise is firm and holds its shape, but shears down to a creamy but “substantial” texture when spread.

- The hair gel is soft and bouncy and offers little resistance to flow on application.

- The syrup flows under its own weight but is slow to pour and drags significantly when spread.

How can three completely different materials deliver essentially the same viscosity measurements?

Well part of the answer is that the mayo and the hair gel are both non-Newtonian, shear-thinning materials, displaying varying degrees of shear thinning, and the syrup is a simple Newtonian liquid with a constant viscosity across a range of shear conditions. Indeed at a lower speed of 5rpm the viscosities diverge: the hair gel viscosity has risen to 96000 cP compared to the 77000 cP for the mayonnaise, and the syrup, of course, still measures 32000 cP.

But the real issue here is that hair gel and mayonnaise, unlike the syrup, are actually far better described as soft solids rather than liquids under many conditions. In that case a simple quantification of two more parameters will greatly improve the relevance of our measurements:

Complex modulus: A measure of the rigidity, or stiffness, of the soft solid structure.

Yield stress: Structure strength – the stress required to disrupt the soft solid structure and initiate significant flow.

This information can be gained from the use of high performance rheometers employing oscillatory techniques such as dynamic stress sweeps.

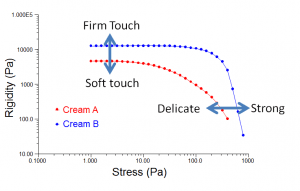

In the example below, Cream A is a soft-to-touch cream that shows easy pick up and adhesion to the dipping finger. Cream B exhibits an altogether more solid texture on first touch, with poor adhesion, necessitating the need to “scrape” collect from the jar.

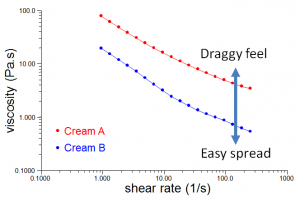

Interestingly, once the creams had been exposed to stresses beyond their yield points, the stiffer and stronger Cream B sheared down to a lower viscosity than Cream A – see viscosity profiles in figure 2.

Please contact us for further information on how a fuller rheological characterisation of your products can benefit you.