A creep test is used for describing the slow steady flow of material under low-stress conditions and is commonly requested for identifying important material properties such as zero shear viscosity and specific viscoelastic properties.

Need to have a creep test performed but lack the equipment or know-how?

Common Applications of Creep Testing

Some of the most common applications for creep testing include:

- Pharmaceutical creams

- An often mandatory test requested by regulatory bodies creep testing captures a lot of vital rheological information about topical pharmaceutical products.

- Pressure sensitive adhesives

- A creep test is used to check for cold flow behaviour. A situation whereby an adhesive can spread beyond the bounds of the backing.

- Transdermal patches

- A particularly pertinent case for creep testing of pressure-sensitive adhesives, cold flow in transdermal patches can increase the area (and thus rate) at which a drug is dispersed to a patient

- Asphalt/Bitumen

- Measuring zero shear viscosity and elastic response to analyse anti-rutting properties of polymer binders

What is a Creep Test?

Simply put, a creep test helps understand two situations: the degree of elastic deformation and rate of viscous flow on the application of a small (i.e. below any yield point) shear stress to a material and the total recoverable elastic deformation on the removal of that stress.

A creep test takes into consideration responses to the application and/or removal of a constant defined shear stress by measuring shear strain over time.

Typically, the small but defined shear stress is applied until an equilibrium shear strain rate is achieved. Once this constant rate is reached, the applied shear stress is removed and the material is allowed to reach an equilibrium state.

There are two primary pieces of information generated by a creep test:

- Zero Shear Viscosity – The most commonly used piece of information generated by a creep test, zero shear viscosity of a material refers to the Newtonian plateau viscosity of the material observed under very low shear conditions.

- Equilibrium Compliance – the elastic response of the material to strain provides a window into the viscoelastic component of a material.

Understanding the Results of a Creep Test

A creep test is plotted as a function of either strain, or more often compliance, against time. Strain can be described as the deformation of material resulting from applied stress. Compliance is the ratio of observed strain to stress applied. Plotting the data as a function of compliance allows for multiple data sets resulting from varying stresses to be plotted together.

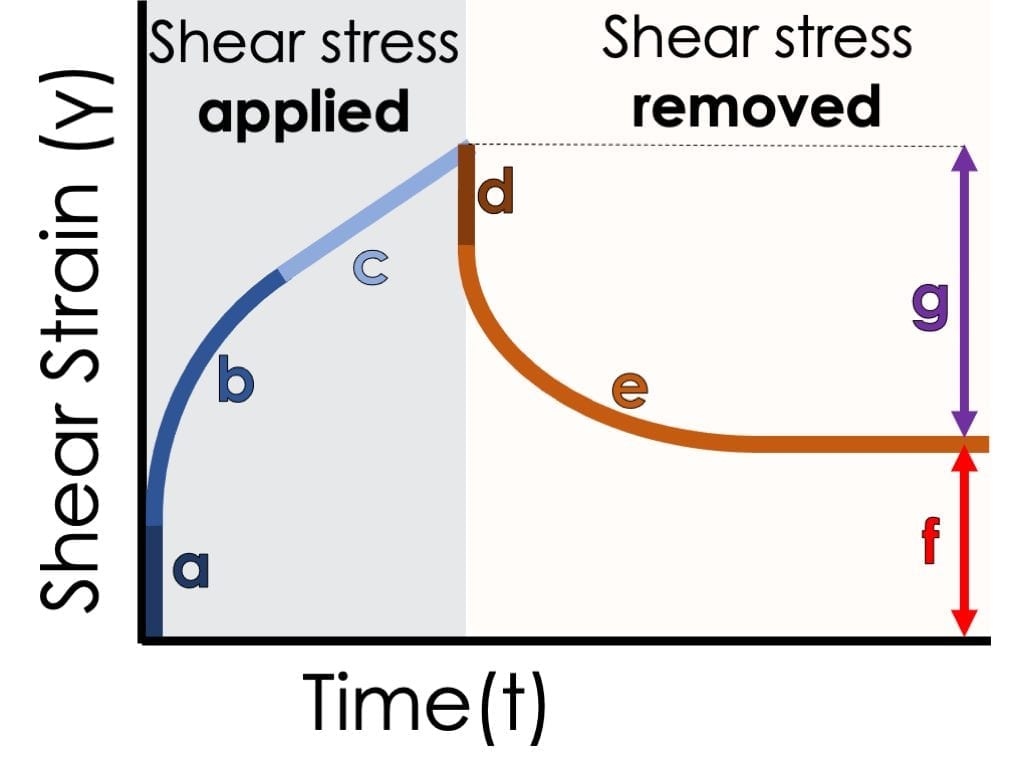

The first part of a creep curve can be divided into three regions; Instantaneous elastic response (a), viscously-retarded elastic deformation (b), and steady-state viscous flow (c). Once the relaxation stage has started, (d) relates directly to (a) and (e) to (b). (f) represents irrecoverable, viscous deformation of the material, and (g) the recoverable, elastic deformation. Each of these areas relates to a specific property of the material being tested:

The first part of a creep curve can be divided into three regions; Instantaneous elastic response (a), viscously-retarded elastic deformation (b), and steady-state viscous flow (c). Once the relaxation stage has started, (d) relates directly to (a) and (e) to (b). (f) represents irrecoverable, viscous deformation of the material, and (g) the recoverable, elastic deformation. Each of these areas relates to a specific property of the material being tested:

- Instantaneous elastic response – the immediate, elastic response of the material to the stress being applied.

- Viscously-retarded elastic deformation – Delayed elastic response.

- Steady-state viscous flow – Entirely viscous response once any elastic response has reached its limit under applied stress. This part of the graph should be a straight line, the gradient of which can be used to calculate the zero-shear viscosity of the material. Extrapolating this straight line back to t=0 allows for the calculation of the equilibrium compliance.

- Irrecoverable viscous deformation – The material has been caused to deform and that deformation is unrecoverable.

- Recoverable elastic deformation – The material has been caused to deform, but once the stress is removed it is able to recover that deformation.

The second part of the creep curve occurs once the viscous steady-state flow has been achieved, and is induced by removing the stress from the material. This results in two further parts to the graph;

- An initial recovery step, correlating to the instantaneous elastic response

- Further recovery, accounting for all of the elastic deformations of the material

Of course, all of this is as observed in a perfect creep flow curve, something very rarely encountered in practice. Interpreting and understanding the practical elements of a creep flow test is often much more complicated.