Surface Tension of Ophthalmics – Mimicking Nature’s Design

When it comes to eye drops and ophthalmic lubricants, surface tension is one of the things nature got right. Ophthalmic products are often formulated to mimic the surface tension found in the eyes’ natural lubricating layer and bolster the volume of liquid available in the eye. By testing the surface tension of your eye drop formulations, be it for regulatory submission or formulation development, you can quantitatively establish and demonstrate similarity to a reference product whilst ensuring quality and pre-screening your formulations to cut back on costly in-vivo tear break-up testing.

When it comes to eye drops and ophthalmic lubricants, surface tension is one of the things nature got right. Ophthalmic products are often formulated to mimic the surface tension found in the eyes’ natural lubricating layer and bolster the volume of liquid available in the eye. By testing the surface tension of your eye drop formulations, be it for regulatory submission or formulation development, you can quantitatively establish and demonstrate similarity to a reference product whilst ensuring quality and pre-screening your formulations to cut back on costly in-vivo tear break-up testing.

If you would like to discuss a comprehensive physical characterisation of your ophthalmic product, please feel welcome to contact us.

The Surface Tension of Ophthalmics and Why It Matters

Getting the surface tension of your ophthalmic lubricant right is key to a well-functioning product. The ideal ophthalmic lubricant should work with the naturally occurring tear layer in the eye, and add to the liquid available for the eye to perform its natural function. Correct surface tension allows the eye drop to work with the eyes lubricating layer, not against it, enhancing the eyes natural ability to stay lubricated. When combined with rheology, surface tension measurements can provide vital insight into the performance of your eye drop.

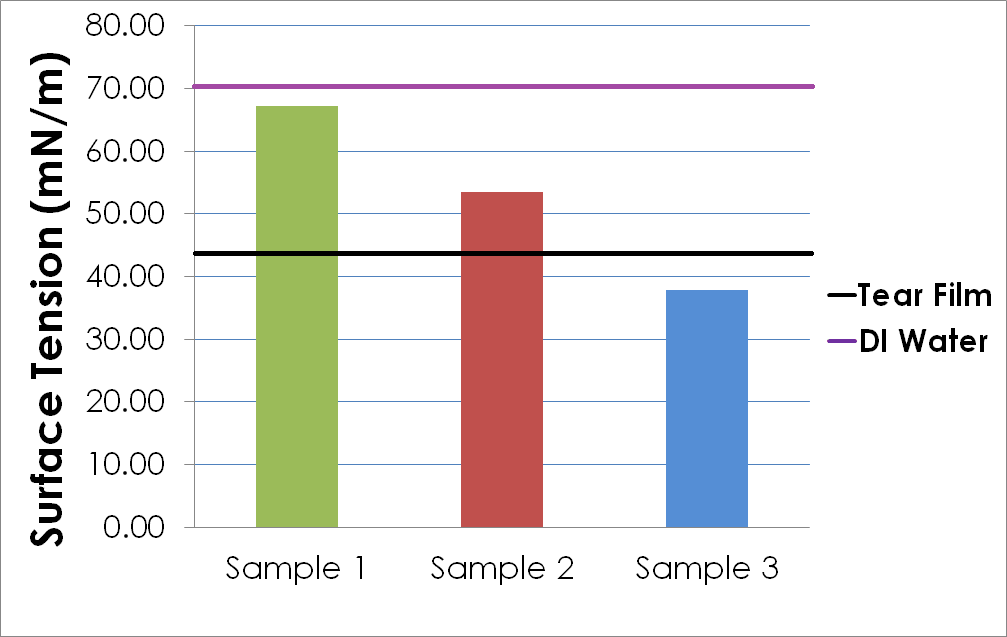

Setting the Goal – The Ideal Eye Drop Mimics the Surface Tension of a Healthy Tear Fluid

In a person suffering from dry eye, the surface tension of the tear membrane is found to be somewhere between 44 nM/m to 53 nM/m. Conversely, optimal tear film stability is found to be between 40 nM/m to 46 nM/m. While lower surface tension values improve wetting properties, surface tension values too low are found to produce non-homogenous film thickness on the eye. As such, the ideal eye drop will have a surface tension similar to the tear film fluid of a non-dry-eyed person.

Rapid Turnaround on Low Volume Samples

We measure surface tension utilising pendant drop shape analysis. This method is quick, highly accurate, less prone to contamination than other methods and can be performed on a relatively small sample volume. Traditional tear breakup testing can take a long time. Compounding that time with a range of formulations can be an expensive and inefficient process. By pre-screening formulations for ideal surface tension, you can cut back on tear break up testing, and save time and money by only testing those formulations which are most likely to be effective.

Surface Tension in Concert with Rheology

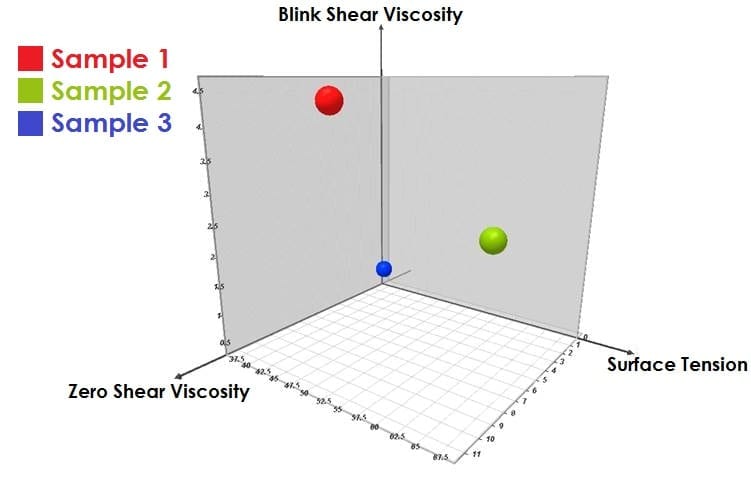

Correct surface tension is a key part of designing a great ophthalmic lubricant, and on its own can be a useful performance metric for pre-screening formulations before an in vivo testing step. When used in concert with rheological metrics such as blink shear viscosity (the viscosity of the eye drop while the eye is blinking) and zero shear viscosity (the viscosity of the eye drop while the eye is open), it is possible to create a full characterisation of your ophthalmic lubricant. Targeting key measurements during formulation can be the difference between making an eye drop that works, and making an eye drop that works great.

For more information on other rheological properties that can work in combination with surface tension, check out our article “Not a dry eye in the house: Eye Drop Rheology”.