Physical stability  testing of colloidal or gel formulations can be a lengthy and labour-intensive process, plagued by uncertainty and doubt.

testing of colloidal or gel formulations can be a lengthy and labour-intensive process, plagued by uncertainty and doubt.

Our Rheology for Stability suite of tests can offer a valuable set of tools for formulators looking to maximize certainty of the shelf life of their products whilst reducing lengthy ageing study periods. The suite of tests, that comprehensively characterises your products in fresh, aged and thermally-stressed conditions, comprises some or all of the following, depending upon your needs:

- Rheological measurements of ageing products

- “Day zero” studies – Rheological profiling of fresh products

- Thermo-Rheology Stress Testing

Get a quote for profiling of your samples

Rheological measurements on ageing product

Typical ongoing stability studies entail ageing a product at a range of temperatures and making either visual observations or, at best, simple viscometer measurements, to identify any changes taking place that suggest instability. Employing high performance rheometry for this task brings two significant advantages:

- The changes taking place in an unstable sample often manifest far greater in the colloidal or gel structure characteristics of a formulation rather than in its flow behaviour. For that reason, testing of structural characteristics such as the rigidity (modulus) and strength (yield stress) may yield more relevant information for stability trials.

- High performance rheometers can be extremely gentle, measuring the rigidity (modulus) and strength (yield stress) of the most delicate of developed structures that can impart physical stability in a suspension or emulsion.

Day Zero Study – Rheological Profiling of Fresh Product

The ability to measure a freshly produced product on day zero and predict its stability one year out is the Holy Grail for FMCG product formulators. However, certain rheological properties that can be measured on day zero have been observed to contribute to good or poor suspension or emulsion stability. Two of these properties include:

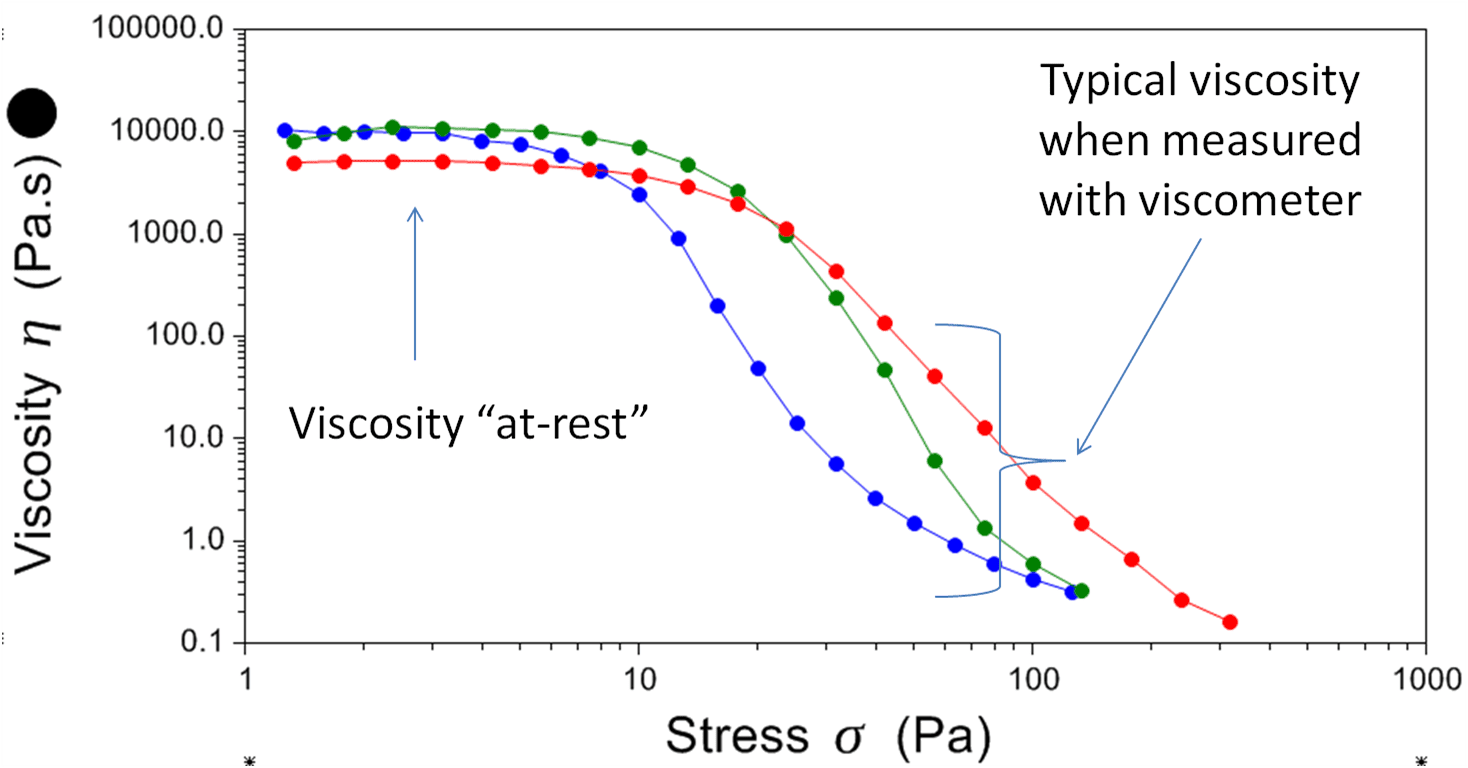

Zero-shear viscosity: The plateau viscosity value achieved at very low shear rates and, therefore, effectively the viscosity of the material in an at-rest condition. High zero-shear viscosities tend to inhibit sedimentation or creaming in multi-phase systems.

Controlled stress viscosity profiling can reveal “hidden” zero-shear “at-rest” viscosity properties.

Thixotropic recovery after shearing: The rapid manifestation of a well-defined colloidal gel network following the cessation of shearing is often associated with more stable formulations, minimizing the time over which suspended particles or droplets can easily interact, flocculate, float or settle.

Thermo-Rheology Stress Testing

Two approaches can be taken here: Freeze/Thaw Cycling and Oscillatory Temperature Swing Testing.

Freeze / Thaw Cycling: Here we take a formulation, perform a rheological profile to capture its structure and flow characteristics then expose it to one or more freeze/thaw cycles, repeating the initial rheological profiling after each freeze/thaw cycle and compare the results to the initial condition.

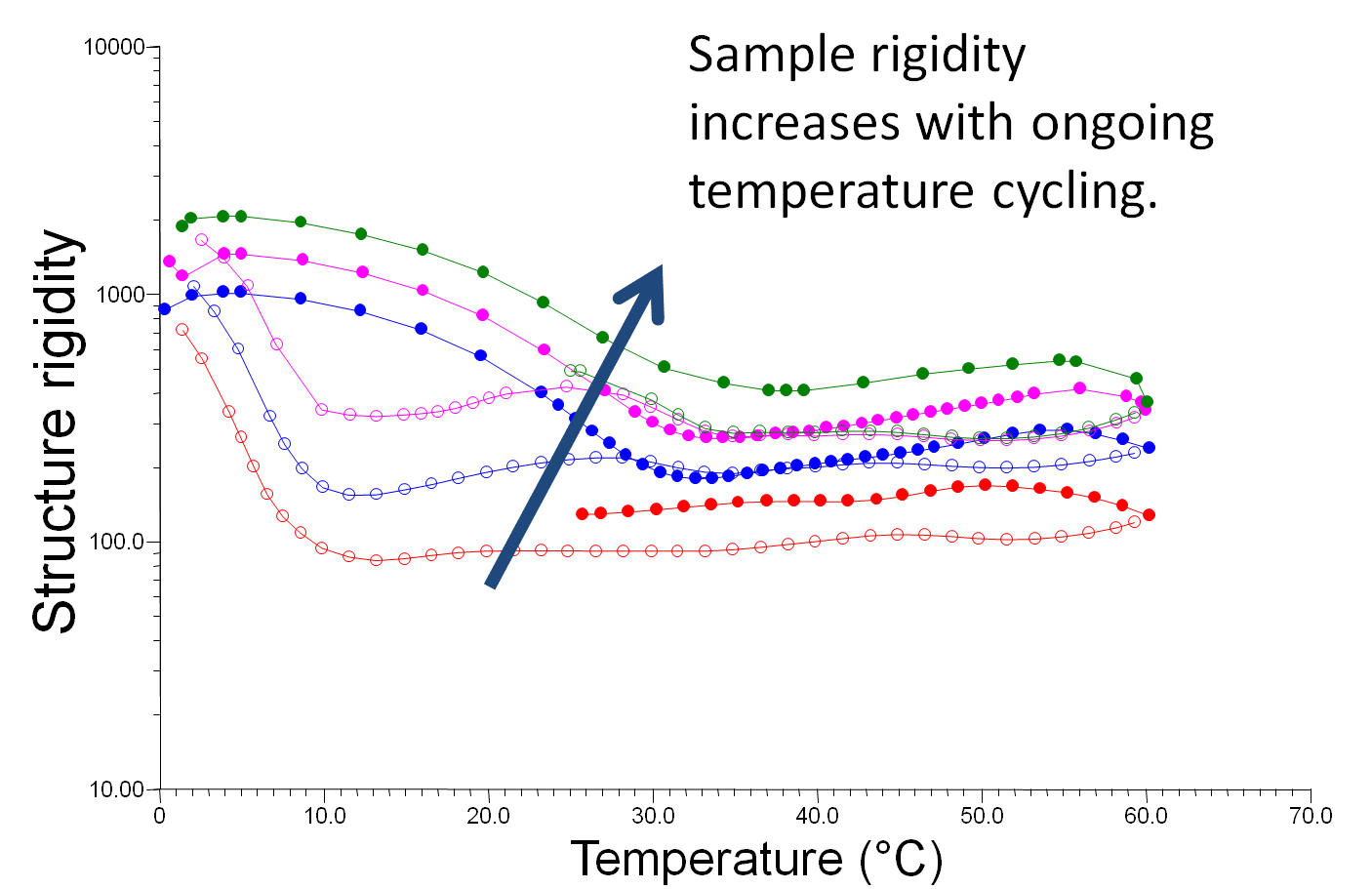

Oscillatory Temperature Swing Testing: This entails applying gentle oscillatory structure assessments to a sample whilst simultaneously exposing it to ongoing thermal stress in the form of two or more regular temperature swings, typically from ambient up to 60°C, back to ambient and sometimes also dipping to low or sub-zero temperatures, all the time identifying any irreversible changes that take place.

The whole test is performed on the rheometer over a period of, typically, one to three hours, depending on the ramp rate, range and number of temperature swings performed.

If you would like to discuss how our Rheology for Stability suite of tests can complement your trials please don’t hesitate to contact us.