Understanding the rheology of grab adhesives is crucial for formulating a product with optimal adhesion behaviour. In construction and DIY, grab adhesives are indispensable for creating strong bonds. Essential to their performance is their rheology, particularly their pre-cured properties. This article explores key pre-cure behaviours of grab adhesives, including penetration, diffusion, and stress resistance. Viscosity, phase angle, yield stress, and thixotropic recovery rate all directly impact an adhesive’s performance.

We procured 3 common grab adhesives, Volden, Gorilla Glue, and Evo-Stick Strong Stuff. Each grab adhesive displayed different rheological characteristics, which could presume differences in performance for the end user.

Avoiding Creep Through Pronounced Structure

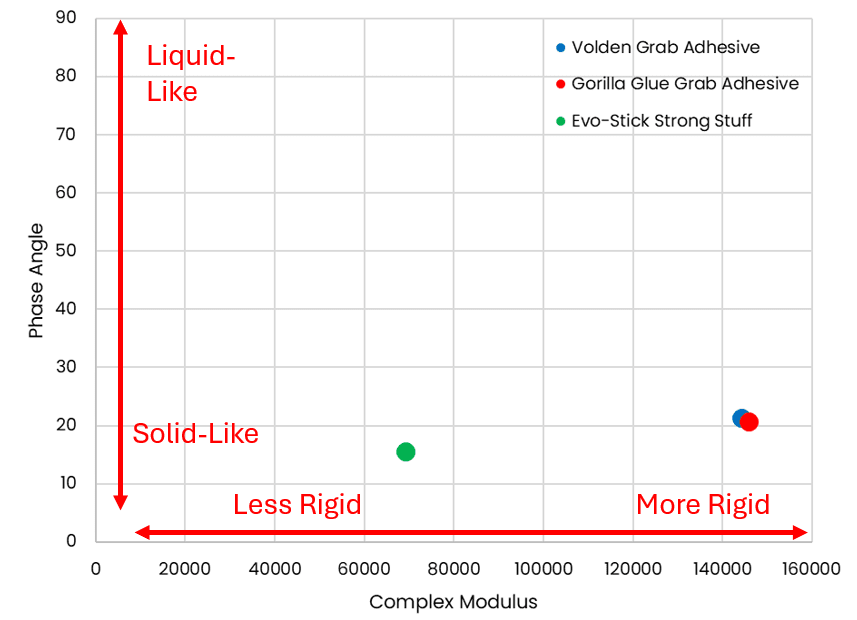

To resist sagging and slumping post deposition, a low phase angle (indicative of a highly structured, solid-like material) helps to resist creeping flow during the materials cure. Phase angle is a key rheological parameter used to describe the behaviour of structured liquids like suspensions, emulsions, gels, and polymer solutions. It measures the balance between elasticity and viscosity under stress, with a low phase angle indicating solid-like behaviour (e.g., jelly bouncing back) and a high phase angle indicating liquid-like behaviour (e.g., syrup flowing).

In terms of their structure, Gorilla Glue and Volden exhibit similarities with regards to their phase angle. However, Evo-Stick Strong Stuff emerges as a distinct outlier. Notably, all three grab adhesives display low phase angles, indicating pronounced structure developing at low stress conditions. Evo-Stick Strong Stuff distinguishes itself by showcasing softer characteristics, as evidenced by its lower complex modulus compared to the Gorilla Glue and Volden counterparts.

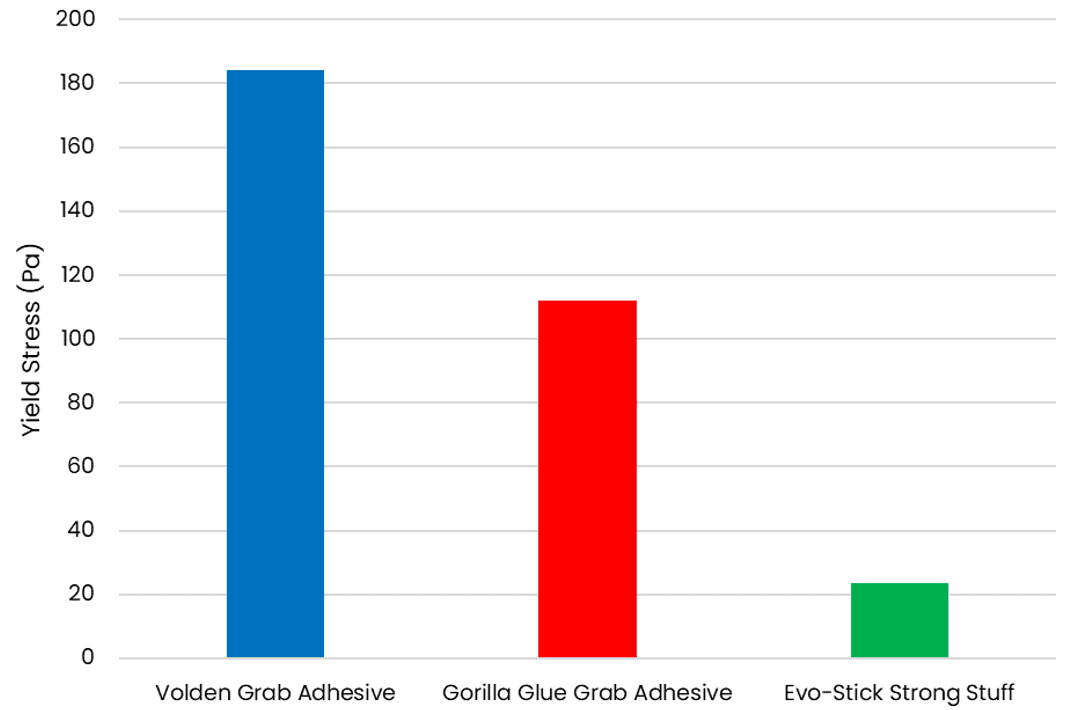

Higher Yield Stresses for Withstanding Greater Forces

A material with higher yield stress is likely to withstand greater forces, as more force is required to initiate flow.

The adhesive samples show a range of yield stresses. Volden displays the highest yield stress whilst Evo-Stick Strong Stuff demonstrates the lowest. This suggests that Volden is likely to withstand greater forces and is ‘more grabby’. The low yield of Evo-Stick Strong Stuff could assist in penetration and maximisation of contact area, aiding the product’s adhesion.

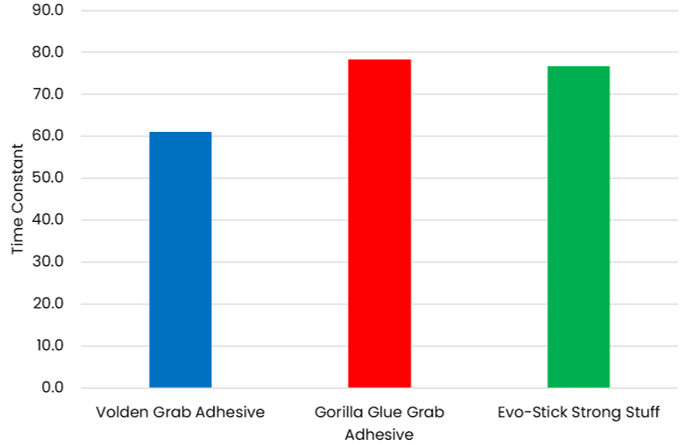

Recovery After Depositing – Time Constants

The recovery of a grab adhesive after the application of shear is significant to its performance. To quantify a materials recovery, we produce exponential time constants which, in this case, are fitted to phase angle. The lower the time constant, the faster the recovery time. Volden recovers the fastest with a come constant of 61.0, a positive trait post application for a grab adhesive. Gorilla and Evo-stick Strong Stuff recover slower with time constants of 78.4 and 76.8; offering potentially easier application, but less optimal post-application. The slower recovery could suggest an increased likelihood of running, sagging, or slumping.

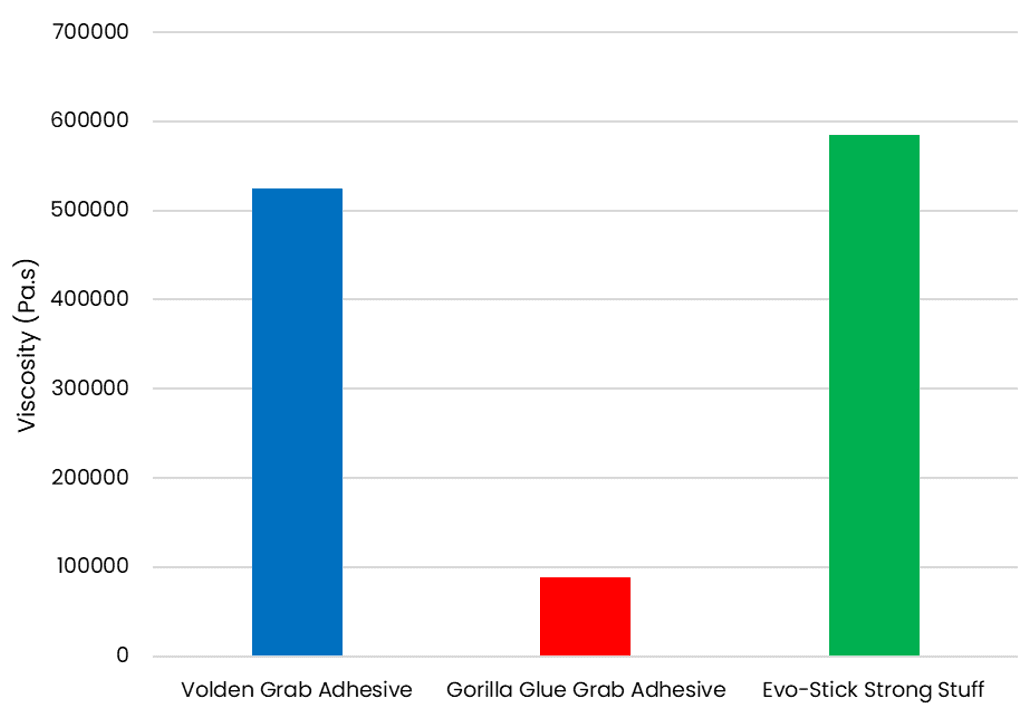

Zero Shear Viscosity: Sag Resistance

Taken from the creep test, the zero shear viscosity values of Volden and Evo-Stick Strong Stuff are similar, with Gorilla Glue much lower. Higher viscosity values are likely a positive trait in terms of the rheology of grab adhesives. Gorilla Glue, a material with significant structure as displayed by the yield stress, shows surprisingly low ‘creep’ or zero shear viscosity.

Summary

The Centre for Industrial Rheology provides an extensive rheological analysis, offering profound insights into the nuanced behaviours and properties of grab adhesives, crucial for various applications in construction and DIY projects. Through our analysis, we have identified distinct characteristics of different adhesives, such as Evo-Stick Strong Stuff’s lower rigidity, Volden’s ability to withstand greater forces due to its higher yield stress, and Gorilla Glue’s slower post-application recovery.

The techniques of our lab aid formulation, empowering formulators with insights into the rheology of grab adhesives for refined formulation, competitor benchmarking, batch-to-batch consistency, or optimising manufacturing processes. By leveraging our expertise in rheological analysis, formulators can make informed decisions throughout the development and manufacturing phases, leading to superior grab adhesive products that meet stringent performance criteria and excel in various applications.

For further information about the rheology of grab adhesives and other techniques we offer, please get in touch.