Powder rheology and flow testing methods can provide a range of insights into predicting whether a powder will cake, flow, crumble, bridge / arch or rathole. While simple test methods such as angle of repose can provide a quick measurement, they lack significant detail and sensitivity to fully describe how a powder will behave in different scenarios.

Powder rheology and flow testing methods can provide a range of insights into predicting whether a powder will cake, flow, crumble, bridge / arch or rathole. While simple test methods such as angle of repose can provide a quick measurement, they lack significant detail and sensitivity to fully describe how a powder will behave in different scenarios.

Temperature, humidity, applied external stresses, static charge, particle geometry and physical dimensions can all play a role in the final observed bulk powder handling behaviour, sometimes with unexpected results.

Contact us to discuss the characterisation of your powders

Shear Cell Measurements and Dynamic Powder Rheology

Powder flowability and powder rheology measurements can be largely divided into two approaches: dynamic measurements and shear cell methods. Dynamic measurements enable the quantification of a range of metrics that are particularly relevant to powders in low stress and mobile situations such as pneumatic conveying, die and cavity filling, aerosolisation and fluidisation. Shear cell measurements deliver metrics where higher stresses are involved and fundamental incipient flow properties are required, for example for hopper design. In addition to flow properties from dynamic and shear testing the bulk properties of permeability and compressibility tell us about the behaviour of the powder when aerated or under compaction pressures.

Cohesion and the Angle of Internal Friction

Shear cell measurements entail applying a range of consolidating stresses to a powder bed and measuring the stress at the point of incipient flow for each. From the “yield locus” obtained it is possible to quantify key flowability metrics including cohesion and the angle of internal friction. Cohesion can be thought of as the intrinsic strength of a powder mass resulting from particle interactions such as Van der Waals forces and electrostatic attraction. Internal friction is a measure of the resistance to flow under the defined consolidation conditions.

For a quick introduction to shear cell measurements, you can also check out this simple explanation video

Powder Flow Function

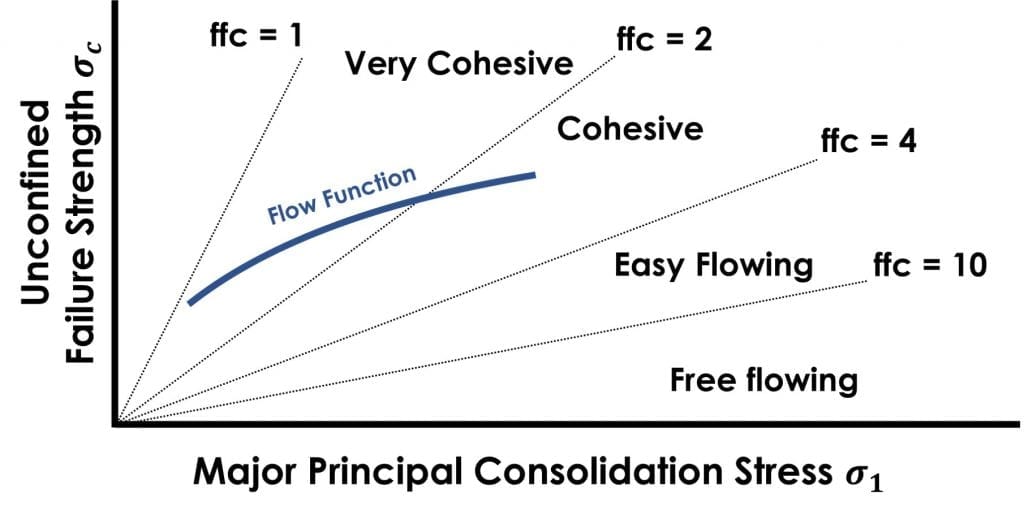

With the construction of Mohr’s circles onto the yield locus the unconfined yield strength at an associated major principle consolidation stress is obtained. The flow function provides a simple and commonly-used assessment of flowability for comparison of powders. The calculated flow function coefficient (the ratio of major principle stress to unconfined yield strength) can then be compared to ranges originally set out by Jenicke and others below:

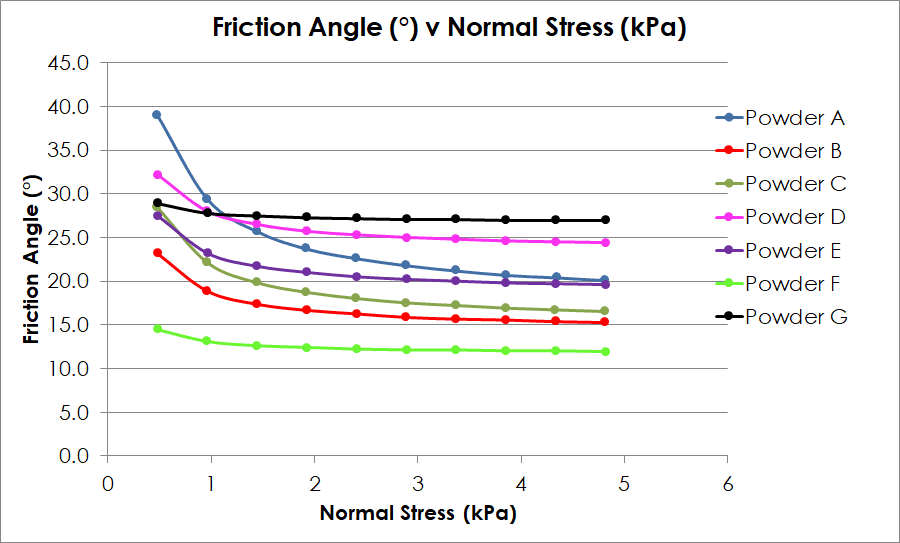

Wall Friction

In addition to the resistance to flow resulting from internal friction powders will display varying degrees of friction against certain surfaces resulting from surface roughness, particle size and distribution and attractive forces. Wall friction and internal friction both subsequently contribute to the propensity for a powder mass to demonstrate undesirable funnel flow and, at worst, form stable rat-holes in a hopper.

Wall friction measurements are performed against a range of relevant surfaces of varying material and roughness. The results can be delivered as coefficient of friction values but are typically presented as angle of wall friction as a function of normal stress.

Dynamic powder rheology

Dynamic testing provides a range of more empirical measurements that entail measuring the energy expended rotating a blade through a column of the powder under test to assess cohesion and flowability. The rate and direction of rotational and axial movement of the blade are chosen depending on the requirements of the test.

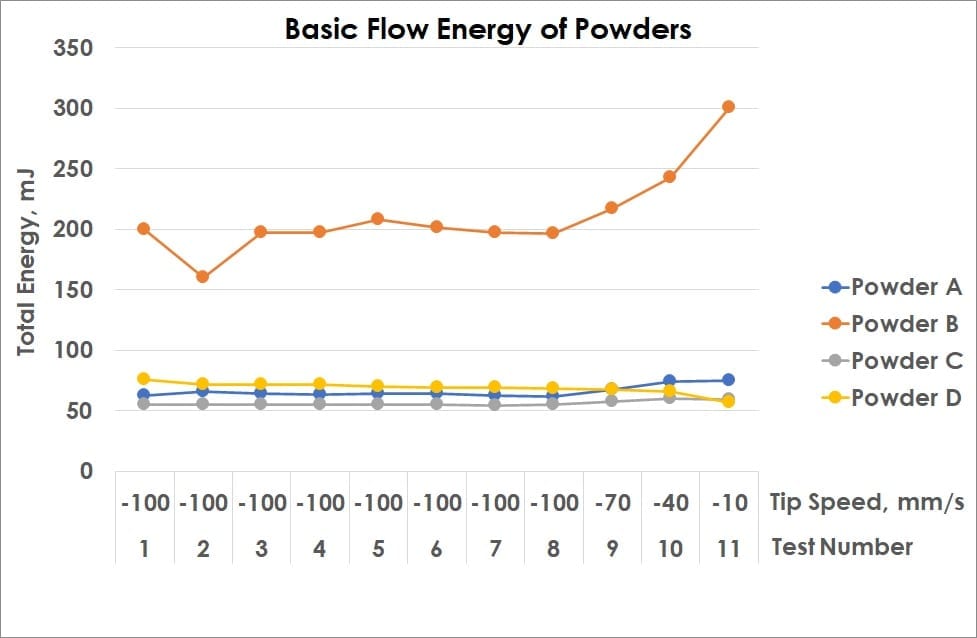

Basic Flow Energy

Basic flow energy is the energy required to drive the blade down through a conditioned column of powder in a relatively confined situation. BFE is measured in mJ but can also be normalised with respect to sample mass to deliver a measure of milliJoules per gram.

Specific Energy

Specific energy is the energy required to lift a rotating blade through a column of powder in a relatively unconfined situation. As such interparticle attraction and powder mass cohesion is likely to play a role.

Stability: Attrition and Segregation

The ability to easily perform cycled dynamic measurements on a single sample make it possible to identify changes in flow energies that can provide indications of either particle attrition or segregation behaviour.

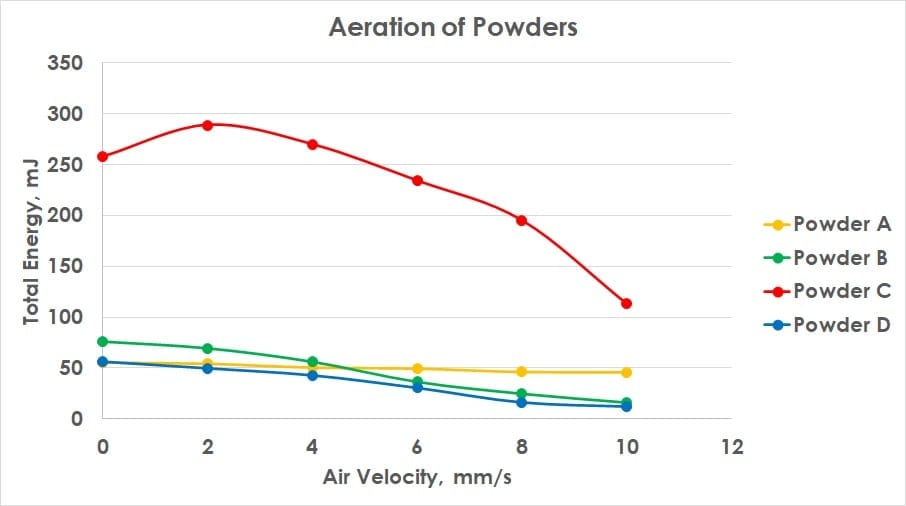

Aeration Studies

Passing air through a column of powder undergoing dynamic testing enables aeration behaviour to be investigated and compared. Flow energy is plotted as a function of aeration velocity with a significant drop in energy with increasing flow signifying potential ease of fluidization.

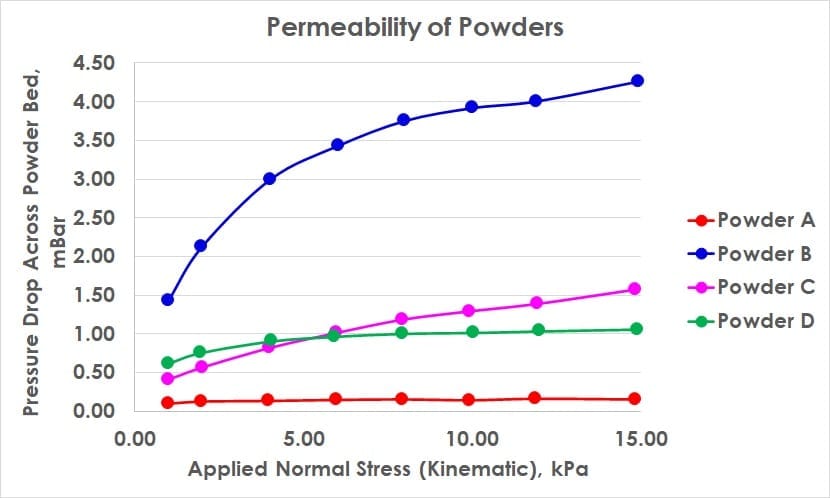

Permeability

Permeability influences the ability for a powder mass to either retain air and maintain a liquid-like state, such as in fluidized bed situations, or to release air to enable rapid filling of dies and voids for tabletting and capsule filling processes. We perform permeability measurements by measuring pressure drop of a stream of air across a powder column whilst controlling air velocity and applied compressive stress. Permeability is a critical material property that impacts on flow in many situations.

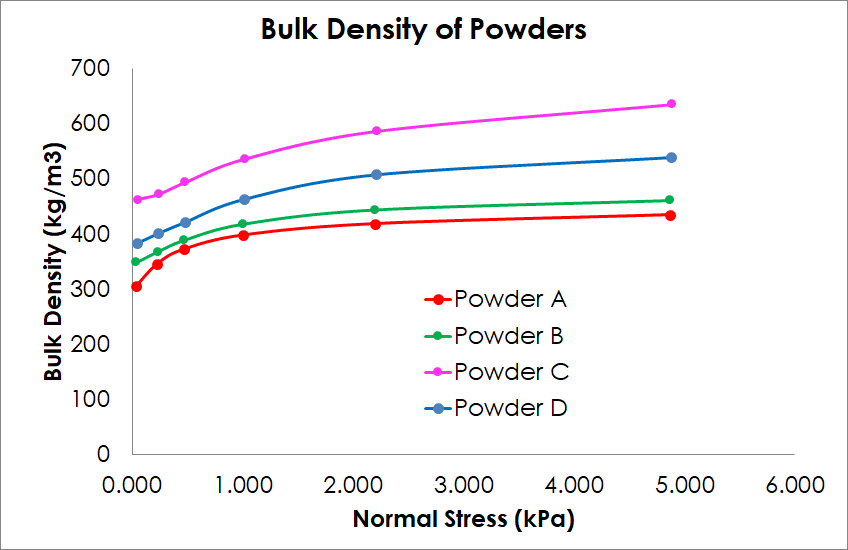

Compressibility and bulk density

The sensitivity of powders to reduce in volume (compressibility) or to combine as a single mass (consolidation/sintering) due to pressure, can be investigated using bulk density methods. This can provide metrics relevant to many storage, transport and processing situations.

The final observed handling behaviour of powders is often the result of complex combinations of the powder’s inherent physical properties. These properties compound one another and can lead to unexpected flow behaviour under specific conditions, and the ability to predict this phenomena is key in ensuring smooth processing of powders. We can offer comprehensive powder characterisation services with a rapid turn around time. Whether you have limited capability, testing capacity, expertise or indeed sample quantity, we can work with you to identify how best to overcome your industrial challenges.