With lithium in short supply, automotive manufacturers are looking to alternative greases for lubrication. Yield stress, viscosity, and thixotropic recovery rate and are amongst the rheological characterisations that will aid manufactures in choosing the most suitable grease alternative for their engines.

The lab at the Centre for Industrial Rheology procured four greases with the same base oil but different thickeners, namely Lithium, Calcium Sulphonate, Copper, and Molybdenum Disulphide. Each grease underwent a variety of tests to explore how they behave under different conditions. Understanding the rheological characteristics of these greases equips machine and engine specialists seeking to substitute their lithium grease with valuable insights about others on the market.

Contact us to arrange rheology measurements for grease alternatives for benchmarking and comparison:

Alternative Grease Viscosities

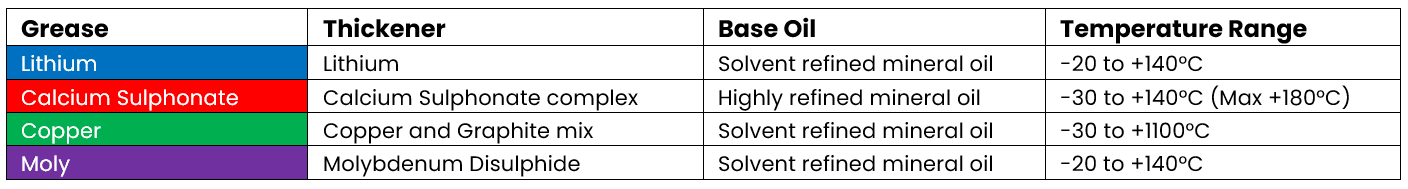

Greases used in automotive engines are certain to have a range of high and low shear rates applied to them, so understanding how their viscosity changes across varying shear conditions is imperative for comparing alternative solutions.

The lab technicians performed a shear rate sweep at 20°C. All samples displayed similar shear-thinning behaviour and similar viscosities. Looking at the data more closely however, we can see that although initially appearing relatively similar, once the greases are exposed to higher shear rates their viscosities begin to diverge.

When applying shear at 0.01s-1 the lithium grease, calcium sulphonate grease, and the copper grease have similar viscosities whilst the moly grease is more viscous. Once the shear is increased to 100s-1, it’s the calcium sulphonate grease that demonstrates a higher viscosity whilst the moly grease behaves more like the commonly used lithium grease.

As with all liquids and semi-solid materials, viscosity alone is not enough to characterise and compare the four greases. In fact, grease displays a commonly observed set of rheological attributes that collectively describe structured liquids. Structured liquids can be thought of as “solids that can be made to flow”; they exhibit liquid-like flow behaviour under sufficient applied stress but revert to soft-solid, elastic behaviour when under gentle stresses.

Understanding a Grease’s Behaviour at Start Up

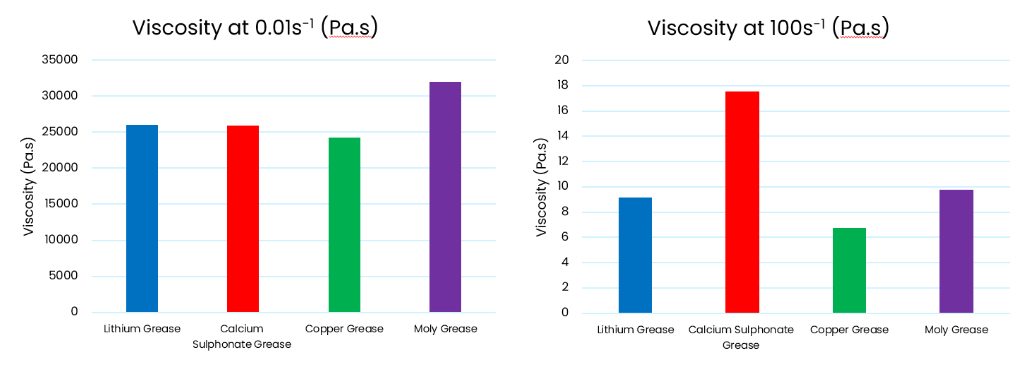

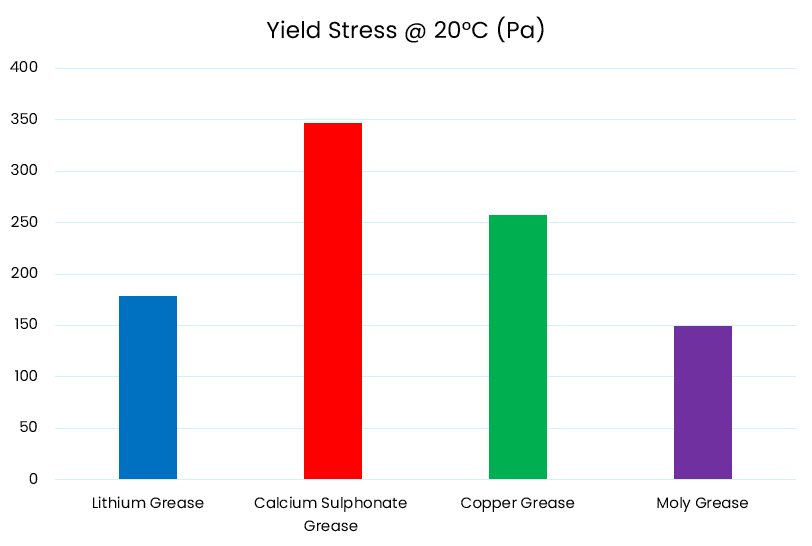

Performing an oscillation stress sweep, the laboratory observed variations in the yield stresses of the grease samples. Yield stress is defined as the stress required to initiate significant flow. The calcium sulphonate sample has the highest yield stress and the moly sample has the lowest, more similar to the lithium grease sample.

Yield stress values may impact the start-up energy. An engine using calcium sulphonate grease will need to apply more stress to its grease to make it flow, compared to an engine using moly grease. Automotive manufacturers must assess the performance of each grease during start-up when seeking an alternative.

Exploring the Melt and Solidification of Grease

Greases used in a vehicle’s engine will undoubtedly experience a range of temperatures.

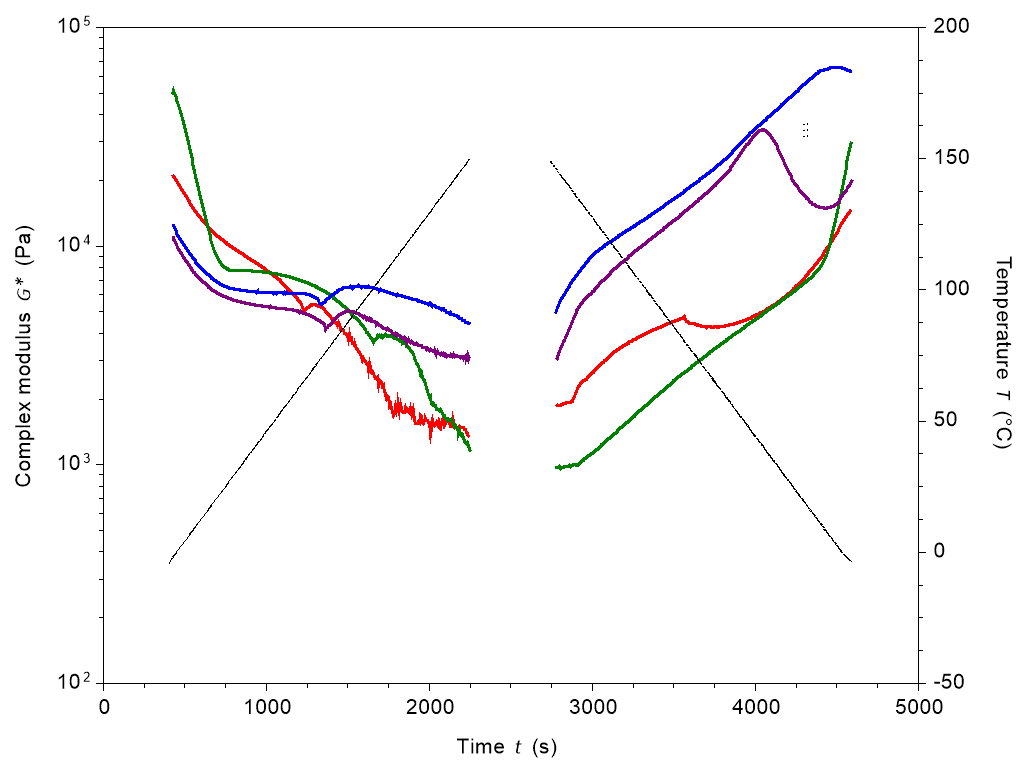

During oscillation temperature ramps conducted on the four greases spanning from -5°C to 150°C, all samples exhibit evident softening upon heating. Subsequently, each grease sample undergoes hardening upon cooling; however, this process does not directly mirror the heating phase, a clear hysteresis occurs.

Automotive manufacturers are required to carefully assess the performance of lubricating greases under varying temperature conditions, encompassing both heating and cooling phases. This scrutiny is essential in identifying alternative lubricants that exhibit consistent and desired behavior across all operational conditions within the engine.

Legend: Lithium | Calcium Sulphonate | Copper | Moly

Explore another study on the thermorheological fingerprints of greases.

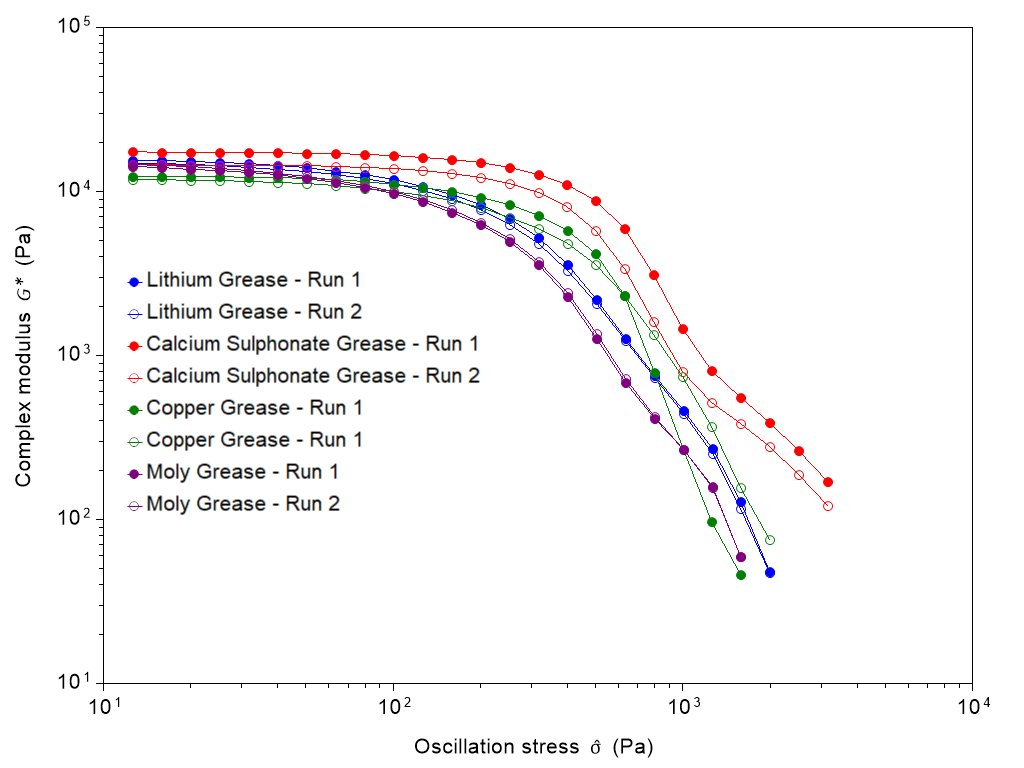

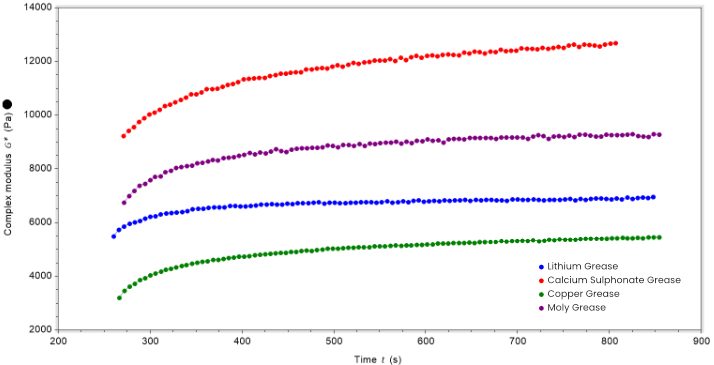

Three-Step-Thixotropy – Complex Modulus

Thixotropy quantifies the recovery of viscosity or structure of a material after it has been exposed to high stress conditions. Each grease sample in our study shows a delayed recovery following the cessation of the high shear breakdown step.

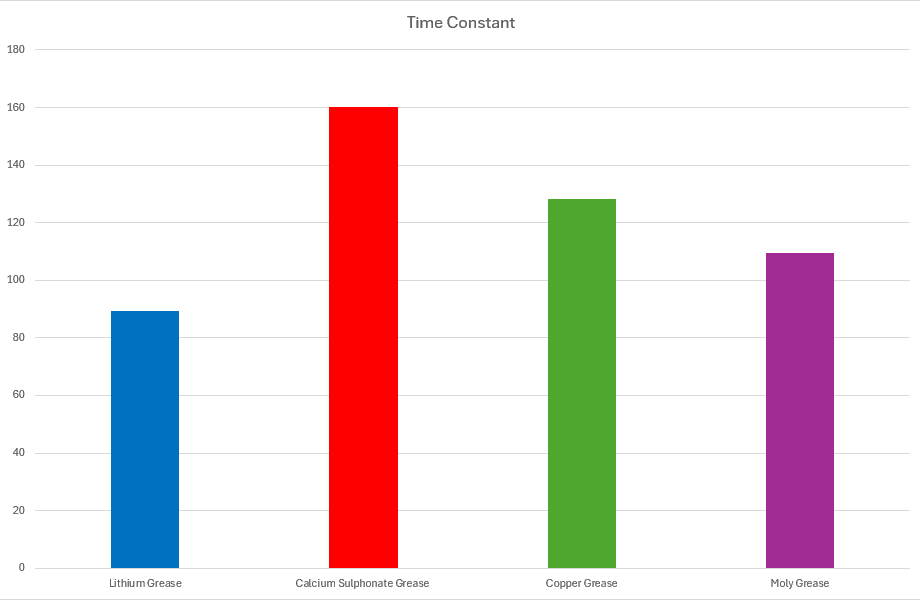

By fitting an exponential model to the recovery curves, it is possible to determine an exponential time constant, which quantifies the rate at which the greases recover towards their viscosity or modulus prior to shearing. A larger value for the time constant signifies a slower recovery process.

With a lower value for time constant, lithium grease is the quickest to reach a plateau, while conversely, calcium sulphonate is the slowest. In assessing the recovery attributes of an alternative grease, moly grease demonstrates a recovery pattern most closely resembling that of lithium grease.

Conclusion

With lithium sources expected to deplete over the coming years, the commonly used lithium grease may need to be substituted with greases comprised of different thickeners. Through rheological analysis of four greases, Lithium, Calcium Sulphonate, Copper, and Molybdenum Disulphide, the Centre for Industrial Rheology has produced useful rheological insights that highlight the variation in behaviour of the different greases.

Whilst there is not an immediately apparent alternative to lithium grease, automotive engine designers and manufacturers can use rheological analysis to better understand how alternative greases may behave in their engines under different conditions and can choose an alternative depending on their exact requirements.

Whether you’re a grease manufacturer or an automotive engineer using automotive lubricants, in-depth rheological data produced by the Centre for Industrial Rheology reduces the volume of in-vivo characterisation required to study and source an alternative to lithium grease.