We investigated the foaming capability of six plant-based milk alternatives using bulk rheology and interfacial rheology methods and identified key differences between the sample set. This work will be of interest to formulators, food scientists and product development scientists alike.

The plant-based market has grown exponentially in recent years as people turn to plant-based alternatives for health and environmental considerations. In 2021, almost a third of Britons used plant-based milks, up from 25% in 2020.

Recreating the taste, sensory and physical properties of dairy milk is of particular interest to formulators and food scientists but is difficult to achieve. A particularly difficult property to recreate is the foaming ability, which is important when preparing hot beverages. The use of rheology to interrogate the foaming-ability and interfacial characteristics of plant-based milk provides valuable insight into milk behaviour and can allow for comparison between brands and milk sources.

Contact us to arrange a lab tour and discuss rheological techniques with our experts

Foam properties for barista plant-based milks

Foam properties for barista plant-based milks

Foamed milk is a key component within many hot drinks purchased from coffee shops, and increasingly at home. A foam that is too stable will outlast the drink and be left behind in the cup however poor foaming, or a weak foam, will add little to the overall sensorial experience. Finding a good balance between these two extremes is key.

Foams are commonly described as “a dispersion of gas bubbles in a liquid” and can be made mechanically by injection of gas, passing steam through a sample, or by whisking a liquid.

Within this study we chose to focus upon foams made by whisking, and probed the foamability, foam strength and rigidity of a selection of plant-based milk alternatives made when chilled (~9 °C) and heated (~60 °C). Barista editions of these alt-milks were chosen for testing as they are likely to have been specifically formulated for foamability.

Foamability of alt-milks

Foamability can be defined as the “propensity of a [liquid] to foam” and is most simply characterised by the volume of foam formed from a given quantity of material. The two rheological parameters that we used for quantification of the foams were:

- Foam strength, which is determined by the stress at which the foam yields i.e. the point at which the linear viscoelastic region (LVR) ends and the foam begins to flow like a liquid (where the bubbles start to flow past each other). The LVR is defined as the region where applied stress does not cause breakdown of the microstructure.

- Foam rigidity, which is characterised by complex modulus. A higher value represents a more rigid foam.

The foams were prepared using a Nespresso Aeroccino 3, both with and without the heat function. The alt-milks tested were as follows:

- Oat Drink 1

- Oat Drink 2 (A “light” version of a different brand, lower in both sugar and fat)

- Coconut Drink

- Potato Drink

- Seed Drink

- Blend Drink (An alt-milk made from oats, coconut cream, and faba bean protein)

When heated, Oat Drink 1, Oat Drink 2, Coconut Drink, and Potato Drink produced an appreciable amount of foam. The foam from Coconut Drink was of note as it had a consistency akin to beaten egg whites, which was considerably different to the other samples. Seed Drink and Blend Drink did not produce any foam when heated.

When chilled, Oat Drink 1 and Oat Drink 2 produced an appreciable amount of foam. Seed Drink produced a small amount of foam consisting of large bubbles which was able to be tested. Coconut Drink, Potato Drink, and Blend Drink did not produce any foam.

Foam strength and rigidity for plant-based milks

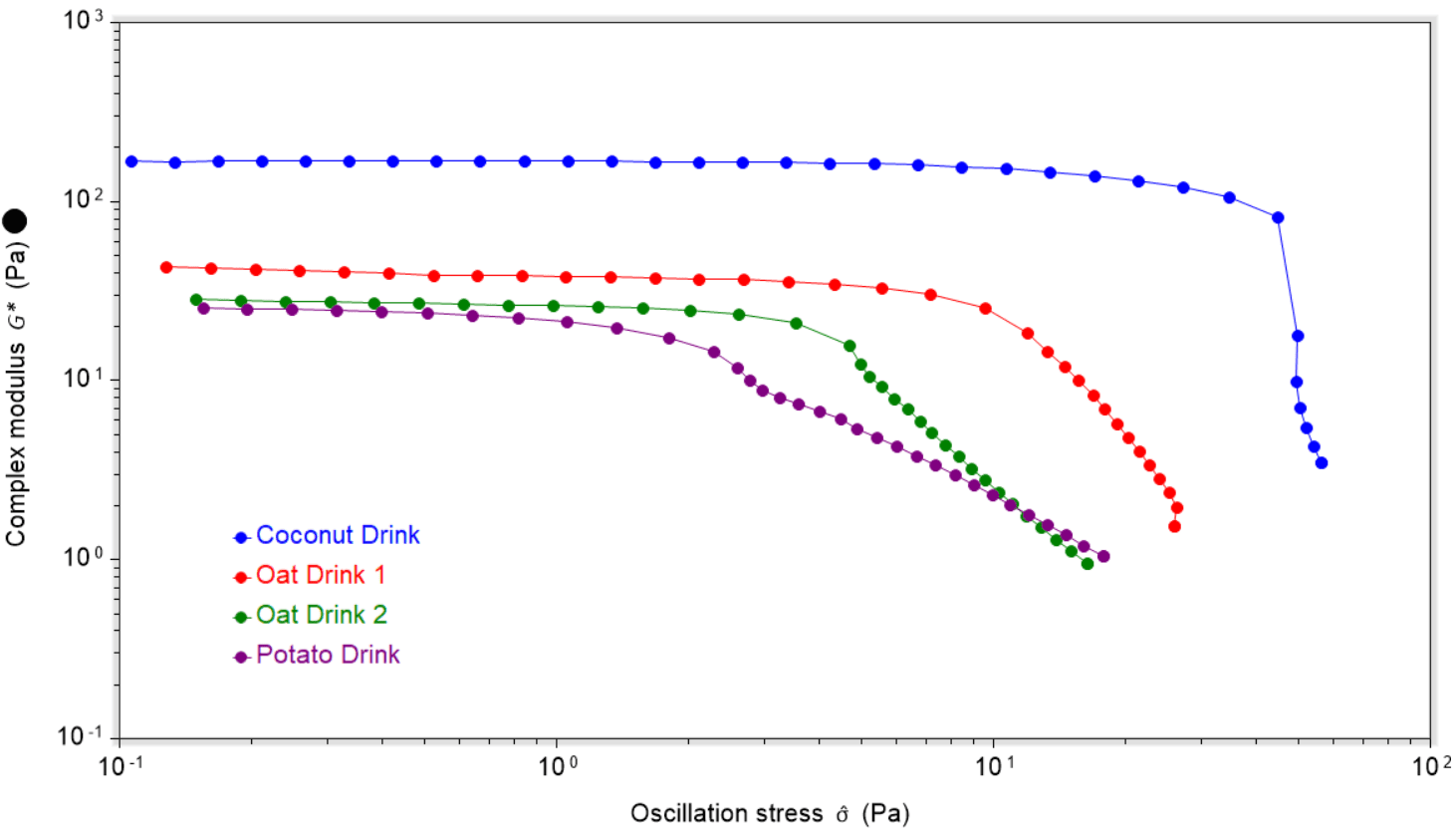

Foams from heated samples

Oscillatory stress sweeps demonstrated how foam strength and rigidity differed between plant-based milks. Coconut Drink produced the most rigid foam, indicated by the largest complex modulus value, and the strongest foam, shown by the largest yield stress value. In this case, yield stress was taken as the point at which the complex modulus value declined sharply.

Potato Drink produced the least rigid and weakest foam. There was a noticeable difference between both the rigidity and yield stress of the Oat Drink foams, which could be due to Oat Drink 2 being a “light” version of the product with both less fat and sugar content.

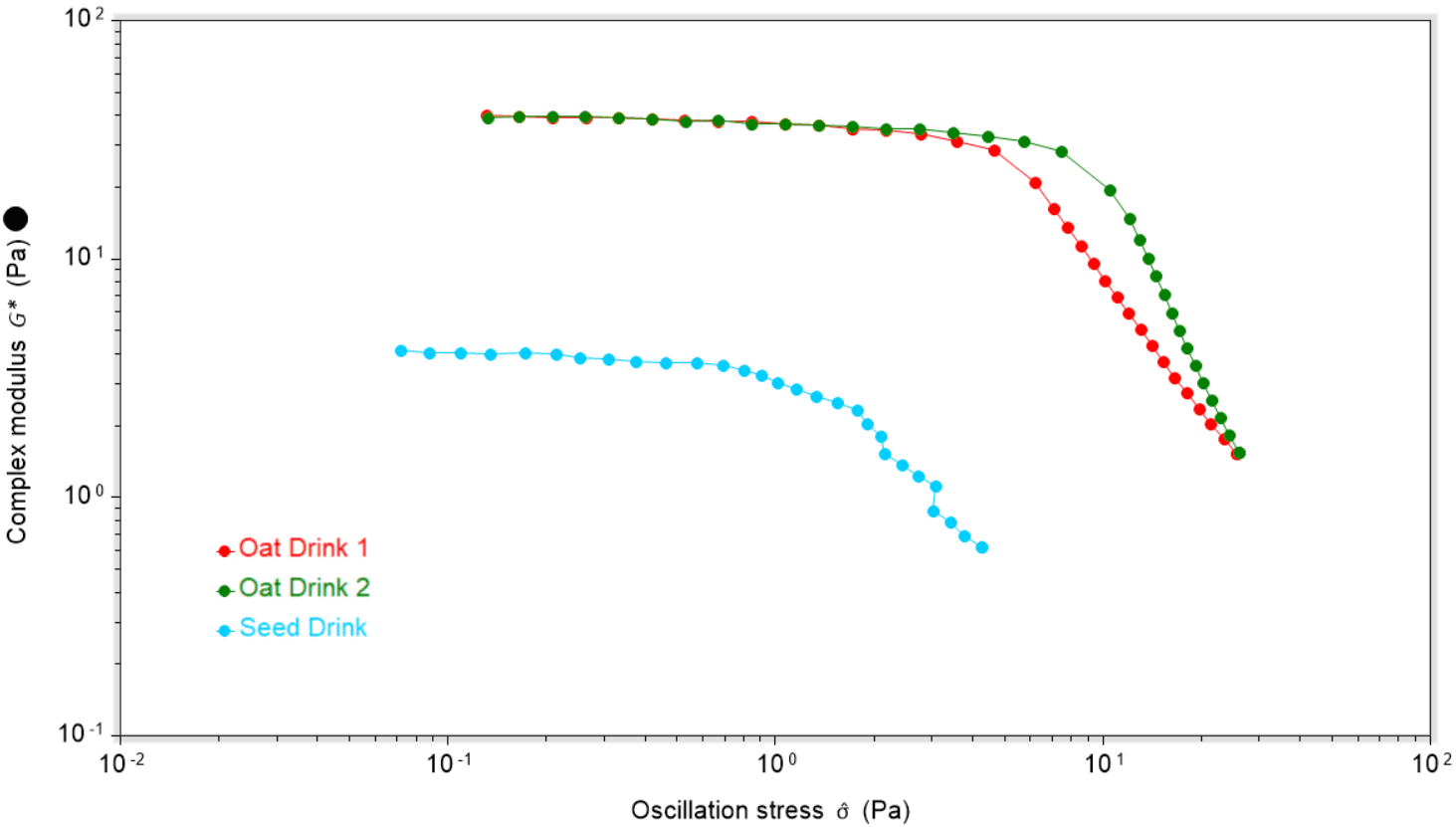

Foams from chilled samples

The two Oat Drink foams had similar rigidity as shown by the similar complex modulus plateau values, but interestingly Oat Drink 1 produced a weaker foam, the opposite to what was seen of the foams when the samples were heated. The Seed Drink foam consisted of large bubbles and was noticeably weaker and less rigid than the Oat Drink foams.

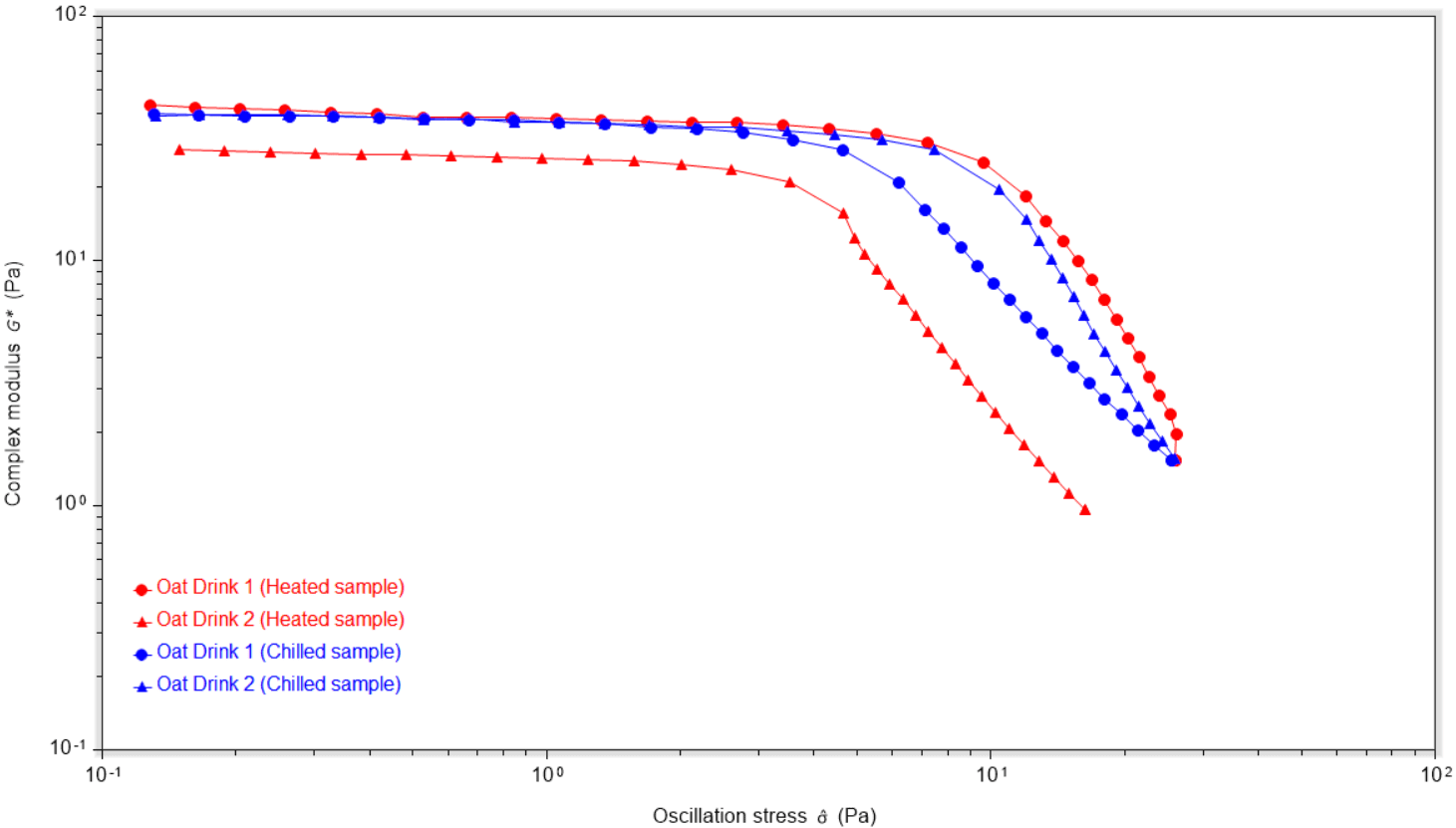

Directly comparing the foams from the two oat samples prepared at different temperatures showed that heating the milk did not affect the rigidity of the foam prepared from Oat Drink 1, indicated by a similar complex modulus plateau, but it did make the foam stronger, as seen by its higher yield stress. Conversely, heating Oat Drink 2 made the foam both less rigid and weaker.

Using dynamic interfacial rheology to investigate plant-based milk liquids

Whilst bulk rheology of a foam can reveal useful properties of its structure, studying the interfacial rheology can provide information on the liquid-gas interface of the foam’s mother liquid, such as surface tension and viscoelasticity.

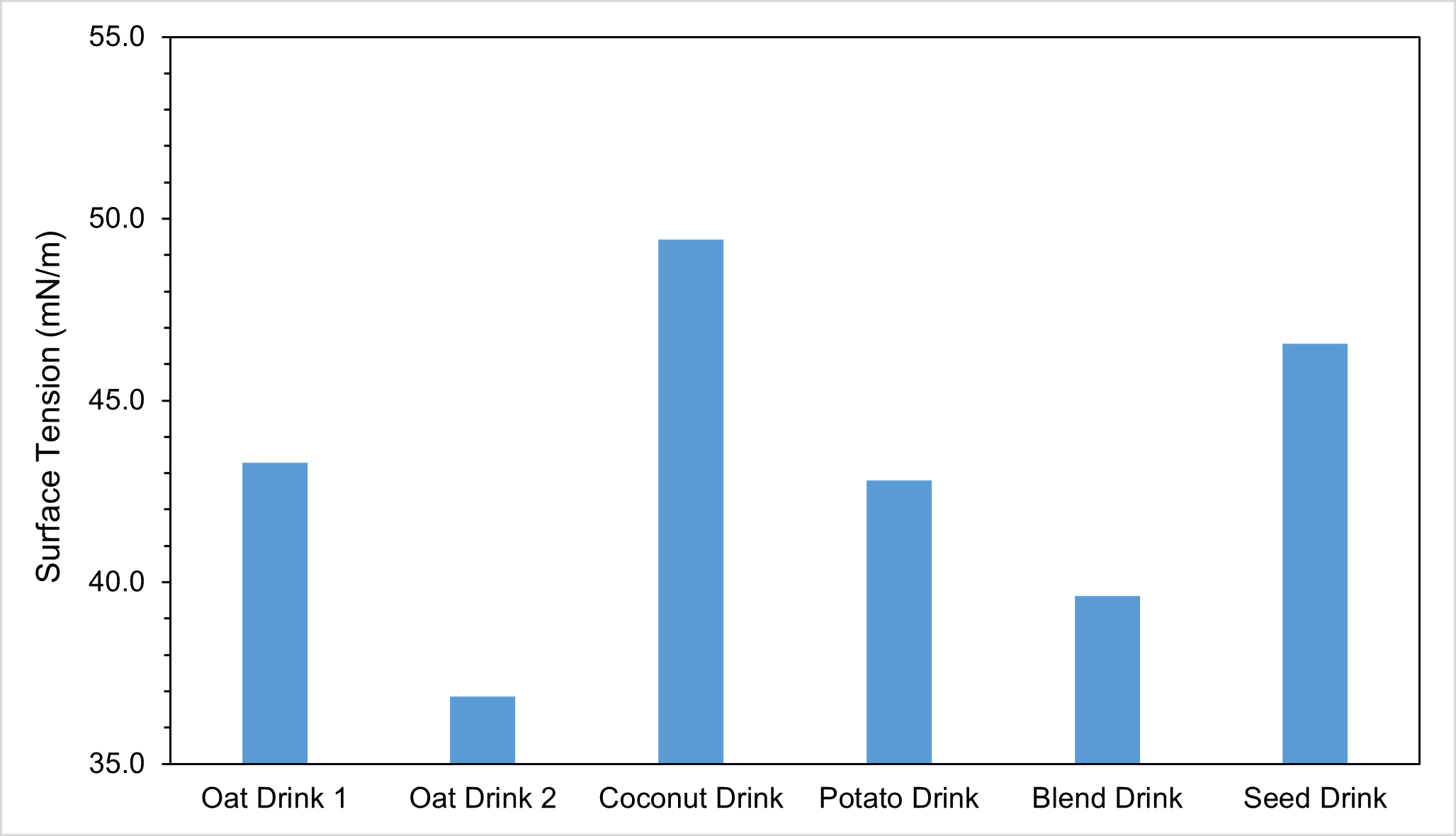

The surface tension is the work required to increase the size of a surface of a given phase. For a substance to foam, a surfactant is required to reduce the surface tension between water and gas; the surfactant adsorbs onto the air-water interface and lowers the surface tension of water so less work is needed to increase the surface area. Surface tension is inversely proportional to the energy required to create a foam, so along with viscoelasticity, it is an important factor to determine.

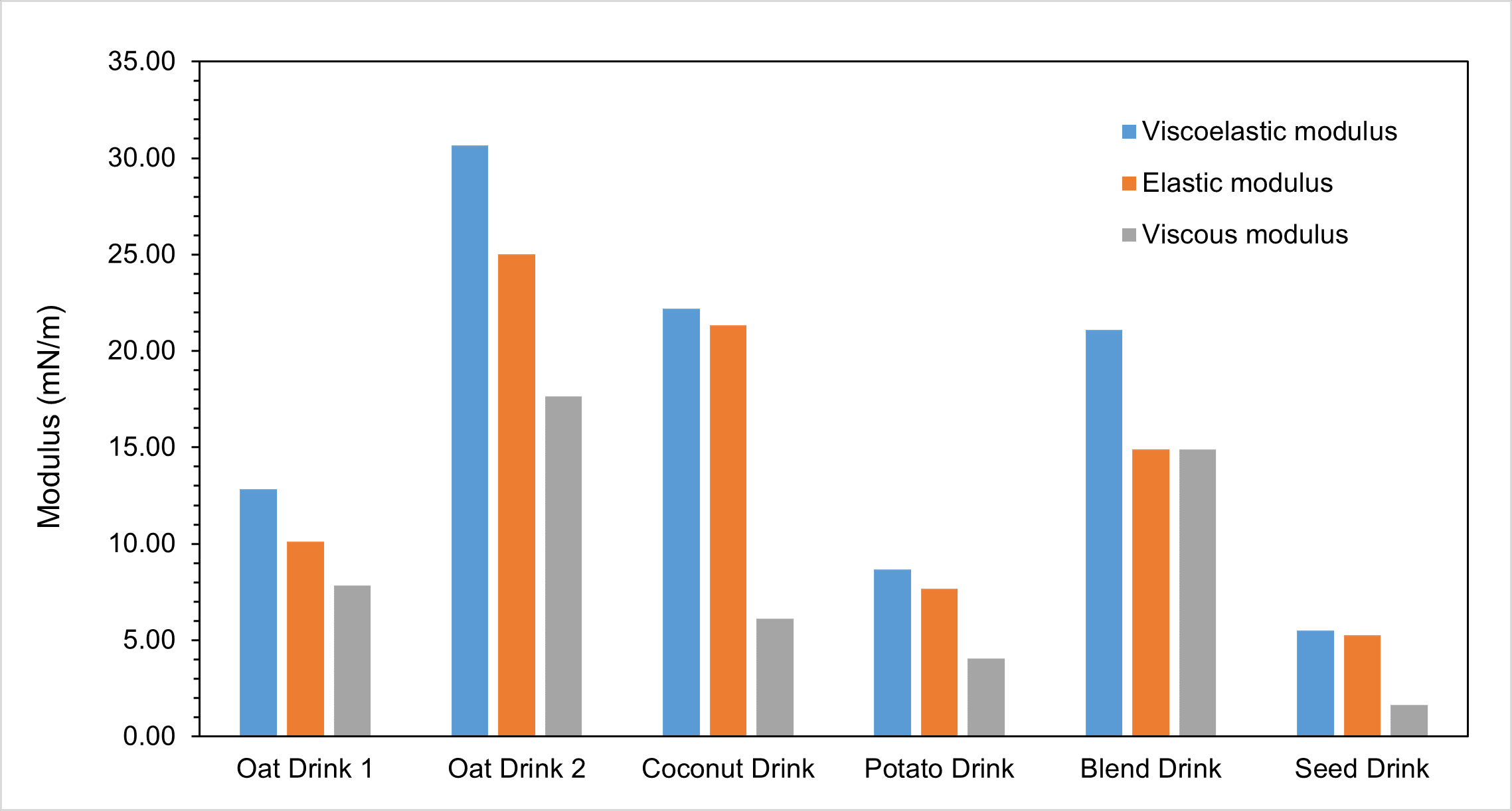

Viscoelasticity can be characterised by the viscoelastic modulus, E, which takes into account two measurable parameters:

- Elastic modulus, E’, the energy at the surface/interface that is recoverable

- Viscous modulus, E’’, the loss of energy at the surface/interface through spontaneous relaxation processes

We used oscillating pendant drop analysis to measure the surface tension and viscoelasticity of all six samples. At room temperature, we found all six samples had an appreciably lower viscous modulus than elastic modulus, which indicated solid-dominant behaviour, except Blend Drink which had very similar elastic and viscous modulus values. The viscous moduli of Coconut Drink and Seed Drink were of note, as they were significantly lower proportionally than the viscoelastic and elastic moduli, compared to the other samples (excepting Blend Drink). Oat Drink 2 was found to have the highest values for each of the three moduli, and Seed Drink was found to have the lowest.

The data show that Coconut Drink had the highest surface tension, 49.4 mN m-1 at room temperature, and Oat Drink 2 had the lowest, 36.8 mN m-1 at room temperature. All samples, predictably, had a much lower surface tension than that of water (~72 mN m-1).

To summarise, we have studied the strength and rigidity of foams from plant-based milk alternatives and also the interfacial properties of their mother liquids. It was found that many alt-milks would not foam when chilled, and that heating them had notable consequences on the foams made, as seen by the Oat Drinks. Coconut Drink made the strongest and most rigid foam when heated and was also found to have the greatest surface tension at room temperature of the tested samples.

For further information about these tests, or the range of tests that we offer, please contact our experts today