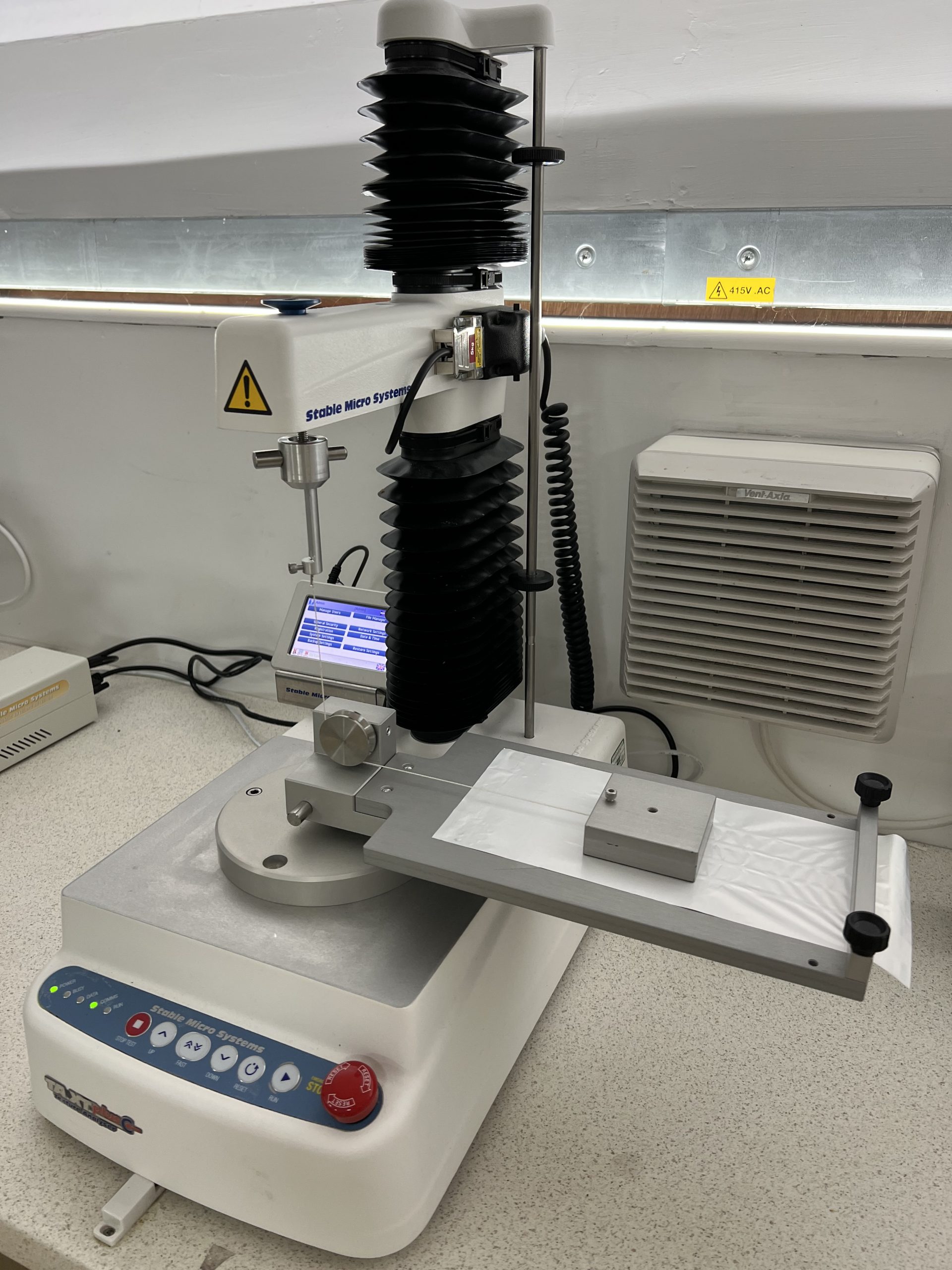

We provide a friction testing service for characterising the ‘static’ and ‘kinetic’ coefficients of friction of plastic film and sheeting. The sled-plane method can also act as a useful starting point for customised methods for investigating or measuring friction force in a number of different applications.

Measuring the ‘kinetic’ and ‘static’ coefficient of friction is of key interest in multiple industries from packaging and plastics, to medical devices, textiles, paints, and coatings.

The sled-plane method can be incredibly useful for getting a qualitative measure for the degree of slip between two surfaces or benchmarking the slipperiness as two surfaces interact.

Our lab is capable of working to ASTM D1894, ISO 8295 and other sled-plane friction methods or indeed investigation friction as a function of sliding speed, find out more out tribology testing on a rheometer here.

We can also provide method development services to design specific protocols for the investigation of friction for a variety of materials or situations. Our lab works quickly and efficiently to provide our customers with coefficient of friction data on a variety of surfaces, range of sliding speeds and range of temperatures.

If you would like to find out how our lab can help you investigate frictional properties between two materials, please feel welcome to contact us.

Friction Testing Service

Friction can be described as the force resisting the relative movement between two objects in direct contact with each other. Friction force tends to scale as a function of the normal force acting to push the two objects of interest together, and as such it can be more useful to describe friction force in terms of a friction coefficient – simply a ratio of friction force to normal force. The sled-plane method is relatively robust and has some key benefits such as being higly versatile and applicable to a number of situations where a simple comparison of friction is of interest.

There are a number of standard methods such as ASTM D1894 and ISO 8295 which focus around the measurement of the frictional properties of plastic surfaces, plastic films or plastic sheets.

Static Friction vs. Kinetic Friction

The ‘starting’ or ‘static’ friction refers to the initial force to be overcome before relative movement or sliding occurs (the static-limiting friction describing the maximum recorded value), and the ‘sliding’ or ‘kinetic’ friction refers to the relative force recorded when two surfaces are sliding against each other. Kinetic friction can also sometimes be referred to as dynamic friction, as its value can be depending on the rate at which the two objects are sliding past each other.

Our lab can help characterise the frictional properties of your material and help indentify appropriate methods and accessories to help you get started.

If you would like to better understand the frictional properties of your material, or would like to discuss a short investigation into how we can help then please feel welcome to contact us.