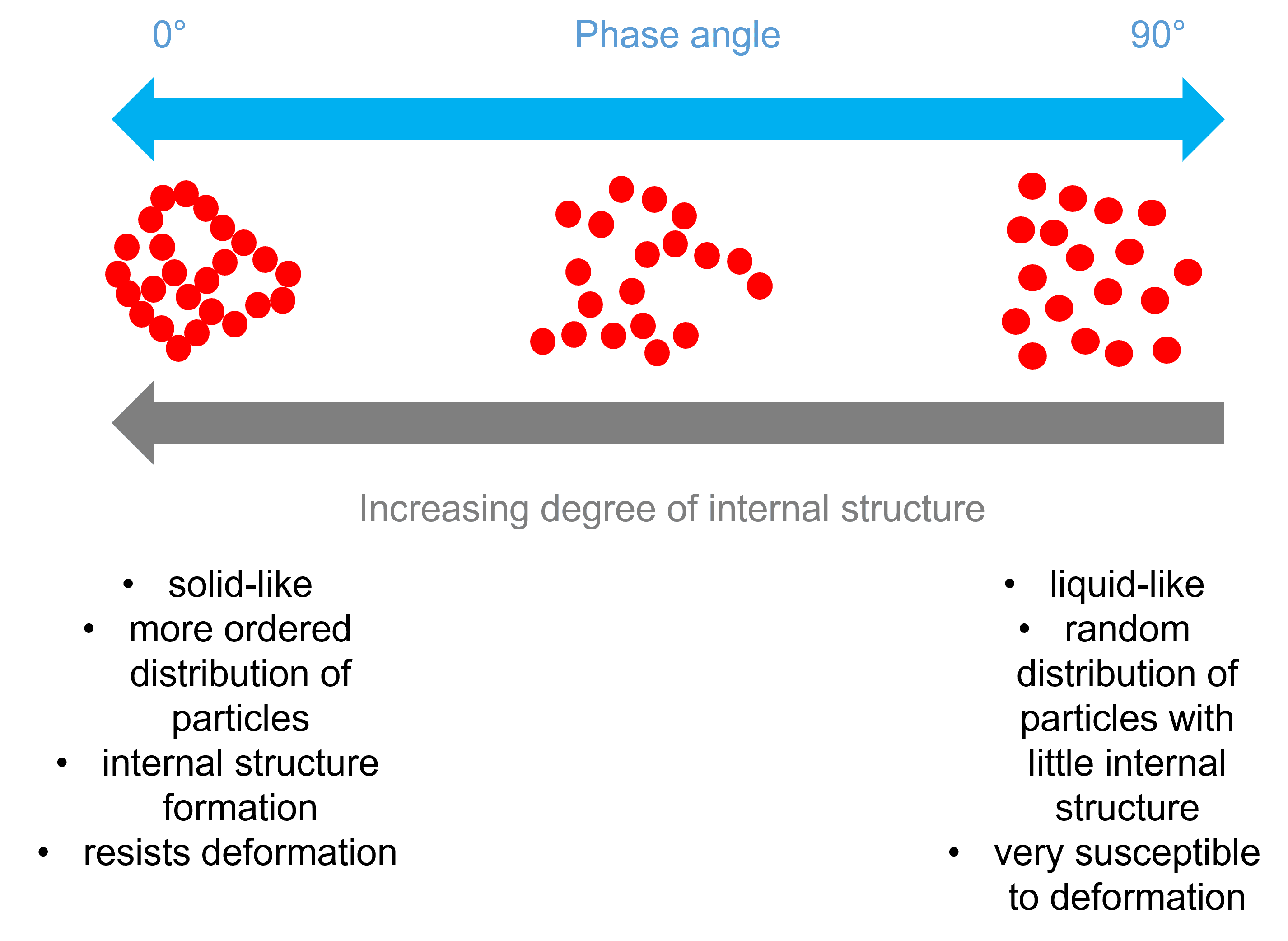

Anybody looking to match the succulence, juiciness and flavour delivery of animal meat in a plant-based product will likely appreciate that the chemical composition of a fat or an oil can have a large impact upon its behaviour. Identifying the temperature at which a fat’s behaviour transitions from liquid-like to solid-like (i.e. the point at which the oil freezes or waxes precipitate) can offer valuable information, particularly in relation to product processing during manufacture and mouthfeel during consumption. One method for exploration of this behaviour is by measuring the change in phase angle.

Phase angle change will show when the material switches from liquid-like to solid-like behaviour and the degree to which the material is solid or liquid. A phase angle of over 45° shows liquid-dominant behaviour and under 45° shows solid-dominant behaviour. Depending upon whether the fat is being heated or cooled, the phase angle change will reveal when the material changes from liquid-dominant to solid-dominant behaviour and the degree to which the material is solid or liquid.

Contact us to arrange a lab tour and discuss rheological techniques with our experts

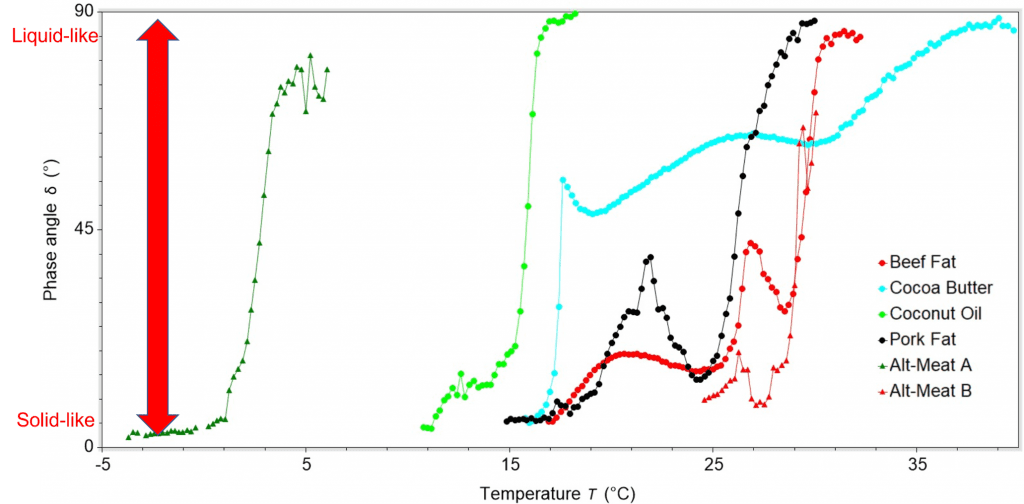

We used phase angle and complex modulus data to scrutinise the behaviour of animal-derived and plant-derived fats over a range of temperatures. We then compared these data with those from fats isolated from two plant-based protein products.

We noticed significant differences in the phase angle (showing solid or liquid dominance) and complex modulus (showing rigidity) as a function of temperature both between the plant-based protein products’ fats and the ‘pure’ fats studied, as well as between each other. The use of phase angle and complex modulus to fingerprint materials are valuable tools in benchmarking products against each other and have wide application within the food industry.

Melting and Cooling Profiles: Animal Fats v Plant-Based Fats

In recent years the plant-based protein market has significantly expanded as consumers look for alternatives to meat-based products. There are two approaches that are currently being pursued. Companies are either using plants to recreate the taste, smell and feel of meat products i.e. by developing plant-based protein, or companies are looking to grow meat in a laboratory, which is often referred to as ‘cultured meat’ or ‘cultivated meat’.

When developing a plant-based or a cultured/cultivated meat product there are several barriers that need to be overcome, especially as consumers are increasingly demanding products that are as close to the original meat-based product as possible. In particular, replication of the succulence, mouthfeel, and behaviour of an animal-derived product during cooking and cooling processes is challenging.

When developing a plant-based or a cultured/cultivated meat product there are several barriers that need to be overcome, especially as consumers are increasingly demanding products that are as close to the original meat-based product as possible. In particular, replication of the succulence, mouthfeel, and behaviour of an animal-derived product during cooking and cooling processes is challenging.

A key component contributing to the flavour and mouthfeel of a foodstuff is fat. In recent years, the rapid development of plant-based protein and vegan products that are specifically designed to perform similarly to original animal-derived product in terms of ‘bite’, juiciness and succulence has necessitated the development of plant-based fats. However, one issue is that the chemical composition and behaviour of animal and plant-based fats are different. Recreation of the melt and cooling profile of an animal-derived fat using a plant-based product is therefore a major hurdle.

We compared the fingerprint melt profiles of two animal-derived fats and two plant-derived fats, which are solid at room temperature, to fats isolated from two plant-based meat products, using oscillatory rheological techniques. In this article, the plant-based meat products are referred to as ‘alt-meat’ products.

Phase Angle/Complex Modulus: A Valuable Tool For Predicting Fat Behaviour

Figure 1 clearly shows that the beef fat and pork fat had a similar melt profile, although they melted at slightly different temperatures. The coconut oil had a different melt profile to the animal-derived fats, showing a gentler change with a longer melt window from solid to liquid. Cocoa butter had a considerably different melt profile; the material changed behaviour from solid to liquid sharply between 13 and 15 °C, and then gradually became ‘more liquid’ between 15 and 40 °C. These results were then compared to the melt profile of the alt-meat products.

Alt-meat product A showed a melt profile similar to coconut oil but at a much lower temperature, melting between 2 and 5 °C. Alt-meat product B melted at a comparable temperature range to the animal-derived fats, but the final liquid fat was ‘less liquid’ than those that were animal-derived. In both cases, the melt profiles were different to those of an animal-derived fat.

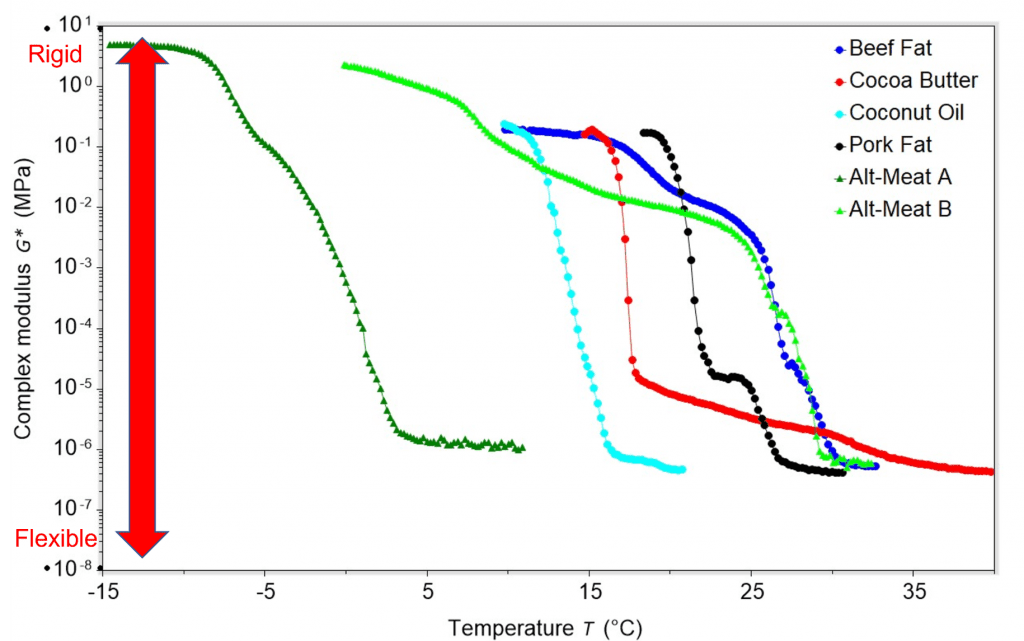

In addition to considering phase angle and the switch in solid-like to liquid-like (or liquid-like to solid-like) behaviour of the oil, the change in complex modulus can also give valuable information. Complex modulus is different to phase angle in that it reveals the resistance to deformation of a soft-solid material, regardless of whether that deformation is recoverable (elastic) or non-recoverable (viscous). This is important, and complex modulus is a key value when assessing the flex and toughness of a material – essential qualities for consumer perception. This is also of particular interest to processing, as minor changes in temperature can have significant changes in the complex modulus and therefore the rigidity of the oil that is being processed.

In all cases there was a considerable increase in complex modulus, and therefore rigidity, of the fats, Figure 2. The most extreme example identified was alt-meat product A, where the complex modulus of the isolated fat increased from 1.2 x 10–6 MPa to 4.8 MPa as the temperature cooled from 5 °C to –15 °C; over a millionfold increase. Several of the fats under study had a significant increase in complex modulus between 15 and 30 °C, the window in which the product may be consumed. The change in complex modulus of the oil in alt-meat product B is over a larger temperature range than for alt-meat product A and is much more gradual. This may mean that the consumer perceives alt-meat product A as more ‘oily’ or even more ‘juicy’ than alt-meat product B during consumption, as the increase in complex modulus (and therefore rigidity) of the oil in alt-meat product A occurs below the likely serving temperature of the product.

The profile of the complex modulus for all fats and products studied is also different, with some materials showing a sharp increase in modulus within a short temperature window (coconut oil), some a more gradual change over a longer temperature range (beef fat), and some a combination of these features (cocoa butter). Interestingly, the ‘final’ complex modulus upon cooling of both the alt-meat products was higher than for the ‘pure’ fats investigated and is likely due to the identity of the fats used within the product itself.

Summary

We have successfully shown the behaviours of fats over a range of temperatures can be investigated using rheology, with both phase angle and complex modulus data successfully collected.

The phase angle revealed the extent of solid/liquid dominance of the oils over a temperature range, which can be used to build an oil profile and fingerprint. The complex modulus provided insight into the rigidity of the oil over a range of temperatures, and how resistant the oils were to deformation once cooled.

At the Centre for Industrial Rheology, we perform the tests in this case study and a whole host of others, working closely with our customers to enable efficient processing, effective Research and Development and excellent end-use products.

Visit our youtube for an archive of video content