Being able to rapidly benchmark and predict shelf stability without waiting months is crucial for formulators wanting to fast-track products to the market. At the Centre for Industrial Rheology, we frequently carry out rheological and interfacial testing with our suite of advanced techniques that deliver powerful predictive contributions to the stability of emulsions and suspensions.

Suncream sprays are typically oil-in-water emulsions that require sufficient structure to maintain homogeneity and prevent destabilisation while sitting on the shelf. However, these products must also reduce in viscosity to allow them to be sprayed effectively, presenting a unique rheological compromise. While we have previously captured the main contributors to spraying performance, in this study, we focus on three key characterisation techniques for probing the stability of suncream spray emulsions:

- Zeta Potential – Electrostatic repulsion between particles

- Zero-Shear Viscosity – Viscosity at close to at-rest conditions

- Yield Stress & Structure – The stress required to make a material flow

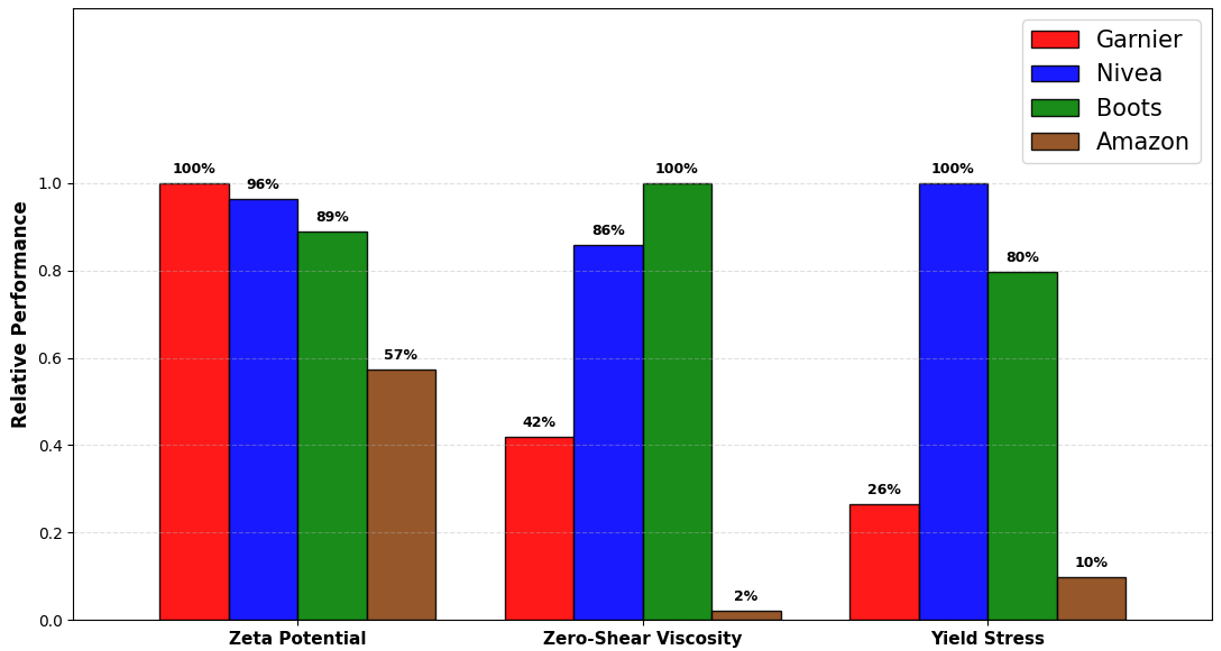

The results in this study showcase significant differences between formulation stability, as highlighted by the relative performances below.

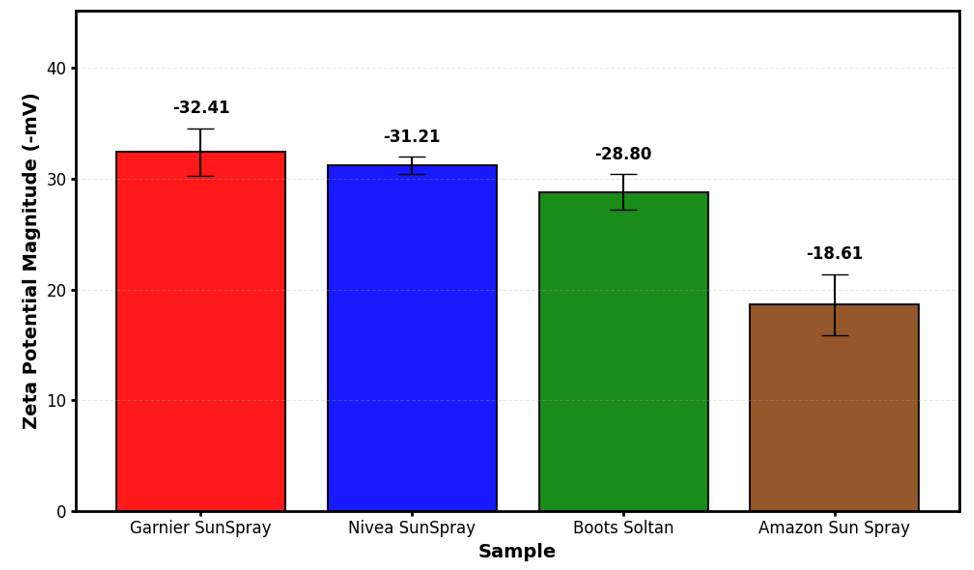

Zeta Potential Measurements for Suncreams

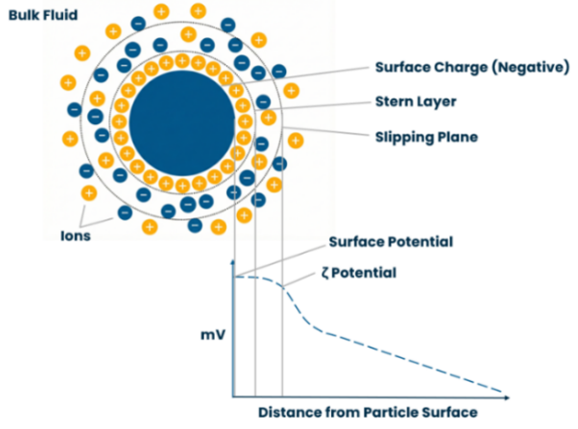

Every particle in a suspension or droplet in an emulsion develops a surface charge. The environment surrounding the particle is visualised in the concept of the electrical double layer:

- Stern Layer – A layer of ions oppositely charged to the particle, bound tightly to the surface.

- Diffuse Layer – A secondary layer of ions that are loosely associated, forming a cloud around the particle.

Within the diffuse layer, a theoretical boundary exists, known as the Slipping Plane. Zeta potential is the electrical potential measured specifically at this slipping plane. In this study, samples were diluted, and values were used as a relative comparison of zeta potential between samples.

The zeta potential results highlight a clear differentiation in the electrostatic forces between particles of these formulations. The Amazon sun spray exhibits a notably lower magnitude, with a mean zeta potential of -18.61 mV. In contrast, samples like Nivea and Garnier maintain much higher values around the -30 mV threshold.

In colloidal science, a zeta potential magnitude below -30 mV often indicates a system that is prone to instability. This is due to the repulsive barrier being weak, and over time, Brownian motions will lead to collisions between particles, resulting in flocculation or coalescence. Over time, these events can manifest as visible phase separation, compromising the product’s long-term stability.

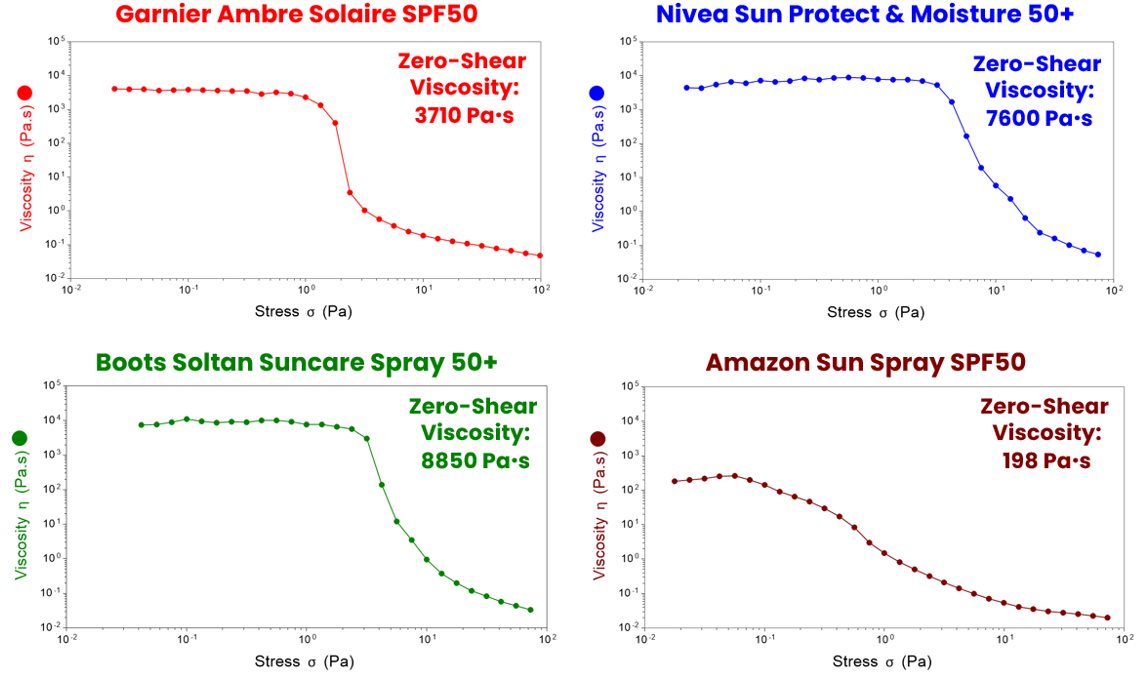

Zero-Shear Viscosity Measurements for Suncreams

The zero-shear viscosity reflects the viscosity of a product when it is effectively at rest. It is arguably one of the most practical indicators of stability, yet it is frequently overlooked as viscometers lack the torque sensitivity to perform such tests. Our research rheometers in the lab offer extraordinary sensitivity, detecting low stresses that extend far beyond the range of typical viscometers. They are capable of detecting rotational speeds as slow as 1 revolution every 3 months. Despite this, we obtain rapid results in as little as 30 minutes. A high zero-shear viscosity in the external phase can be desirable, as it helps to immobilise particles and droplets.

Boots Soltan exhibited the highest zero-shear viscosity, while the Amazon formulation demonstrated a significantly lower zero-shear viscosity than all other competitors. Despite these stark disparities at rest, the high-shear viscosity values converged significantly; notably, Boots (0.0334 Pa.s) and Amazon (0.02 Pa.s) displayed comparable behaviour under high-shear conditions. This underscores that a high zero-shear viscosity, essential for stability at rest, does not inherently compromise a product’s sprayability or spreadability. The Boots formulation, in particular, demonstrates a superior shear-thinning profile.

Yield Stress and Structure Measurements for Suncreams

To get further insights into stability, we go beyond viscosity to look at viscoelasticity and the concept of yield stress. Yield stress is the minimum amount of stress required to make a material flow. Think of it as the “strength” of the internal network when the product is sitting still. A sufficient yield stress acts as a physical net that immobilises particles or droplets. If the yield stress is strong enough to counteract the gravitational force exerted by the dispersed particles, sedimentation and creaming are effectively inhibited, aiding long-term shelf stability.

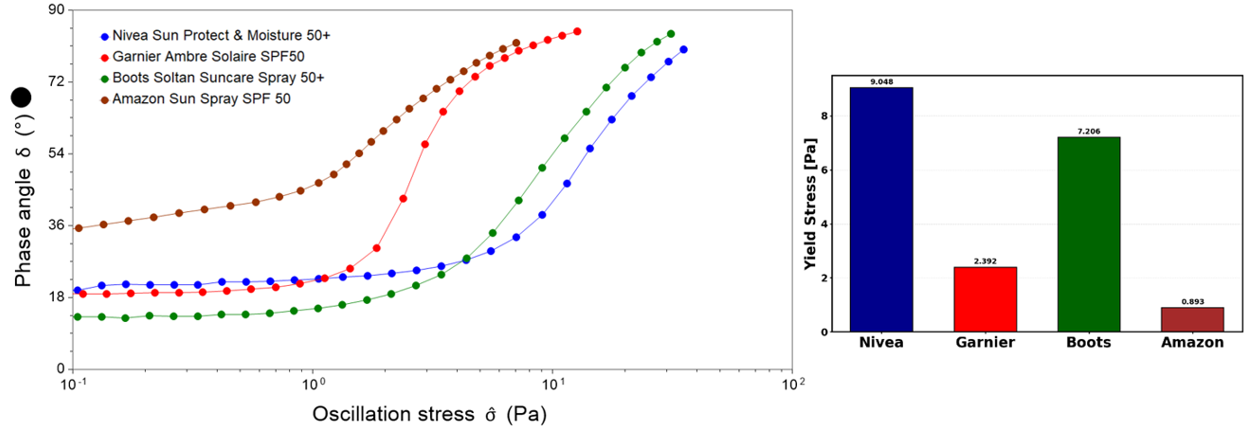

To measure this, we employ oscillatory techniques, where we gently “wobble” the sample to allow us to probe the delicate internal structure present without destroying it. A key metric in this analysis is the phase angle. This metric quantifies the material’s state under oscillatory stress, with a phase angle of 0° indicating a purely elastic solid, while 90° indicates a purely viscous liquid.

Boots displayed the lowest phase angle at low stresses, indicating a more elastic structure at rest compared to the others. Nivea exhibited the highest yield stress, which suggests better shelf-life stability. Amazon’s lower yield stress can be seen as an advantage through an easier actuation force for spraying; however, as seen with the zero-shear viscosity data, it is compromising stability at rest in the bottle.

Summary

The data collected in this study revealed that the Amazon formulation operates in a high-risk zone for emulsion instability. By underperforming across all three metrics, zeta potential, zero-shear viscosity, and yield stress, the product is inherently prone to instability on the shelf. Conversely, the other formulations demonstrate that it is entirely possible to formulate a product with enough structure at rest without sacrificing the low viscosity required for spraying; with the right rheological profile, you can have both.

At the Centre for Industrial Rheology, we can help to remove the guesswork from formulation development by utilising our wide suite of synergistic techniques. Whether you are looking to benchmark your product or troubleshoot an issue, we provide high-precision testing to give you the data you need to formulate with confidence.

Related Articles;

Optimising Rheology and Dynamic Surface Tension for Sprayable Suncare Formulations

Predicting Formulation Stability: Advanced Insights for Suspensions and Emulsions

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.