We have previously explored the impact of different climates on powder flowability, demonstrating how a single seasoning powder can flow freely in arid climates such as Arizona, but could potentially cause problems in high-humidity climates such as Malaysia.

We have previously explored the impact of different climates on powder flowability, demonstrating how a single seasoning powder can flow freely in arid climates such as Arizona, but could potentially cause problems in high-humidity climates such as Malaysia.

Another important aspect in this area is that the flow behaviour of different powders can vary notably when exposed to moisture, despite their comparable size and visual similarity. A production line optimised for handling Paprika seasonings may be expected to handle a Cajun blend or Piri Piri seasoning with the same operational consistency, even though their moisture response may differ significantly.

Overlooking this variability can lead to numerous processing complications, including unexpected production stoppages. Different seasonings will inherently have varying levels of salt, sugar, oil, and anticaking agents, which influence their hygroscopicity. This study aimed to explore a question: When humidity conditions change, why does one powder continue to flow while another struggles greatly?

Contact us to arrange a discussion on powder measurements with our experts

Hygroscopicity of Powders

To understand why seasonings may behave differently under identical conditions, the concept of hygroscopicity must be understood. Hygroscopicity is the intrinsic ability of a powder to absorb moisture from the air. Not all powders are equally hygroscopic; some can remain relatively dry even at high relative humidity, while others begin to absorb water at much lower humidity levels.

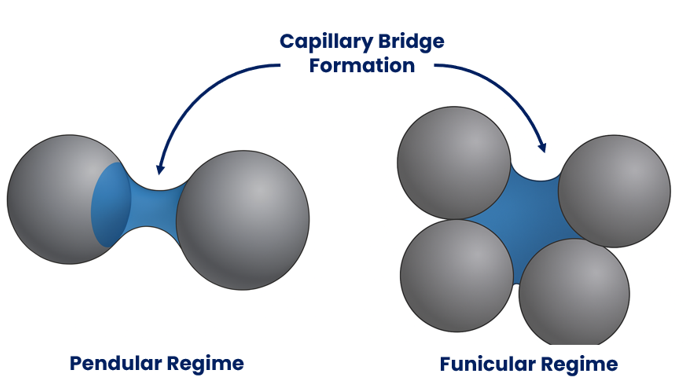

When a highly hygroscopic powder is exposed to higher humidities, it acts like a sponge. The absorbed moisture can condense at contact points between powders, forming thin liquid menisci. These menisci generate capillary forces, which act to pull the particles together, creating liquid capillary bridges.

The presence of these capillary bridges increases particle adhesion, making powders more prone to agglomeration and reducing flowability. Highly hygroscopic powders encounter situations where these liquid bridges can enter the funicular regime. In this regime, individual capillary bridges begin to merge into larger clusters, forming a single liquid network that connects multiple particles.

This is why two red seasoning blends may look similar on a spec sheet but behave completely differently in a hopper. Suppose one blend contains ingredients with a higher affinity for water, such as amorphous sugars or salts. In that case, it will form liquid bridges far more readily than a less hygroscopic counterpart.

Quantifying Hygroscopicity Differences in Seasoning Powders

Quantifying Hygroscopicity Differences in Seasoning Powders

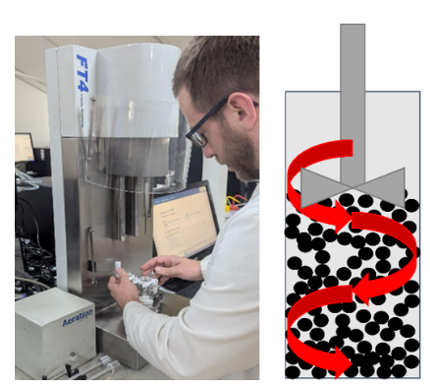

To quantify differences in hygroscopicity, we selected three distinct commercially available seasonings to test using our powder rheometer.

- Paprika

- Blackened Cajun

- Piri Piri

Each sample was tested based on two environments.

- Pre-conditioning – Samples underwent an initial mechanical conditioning cycle. This step involves passing the rheometers’ impeller through the powder to break up and loosen agglomerates caused by storage, ensuring a consistent starting point for all three materials. At this stage, the powders were at ambient humidity.

- Environmentally conditioned (80% relative humidity) – The samples were then placed in our climatic chamber and conditioned at a constant 80% relative humidity for 24 hours. This high-humidity setting was chosen to simulate tropical conditions that can cause significant flowability challenges.

We utilised dynamic powder flow measurements to measure the total energy required to move the impeller through the powder, with higher values reflecting greater resistance to flow. This highly sensitive method is able to detect subtle changes that basic tests, such as the angle of repose, may miss.

Results

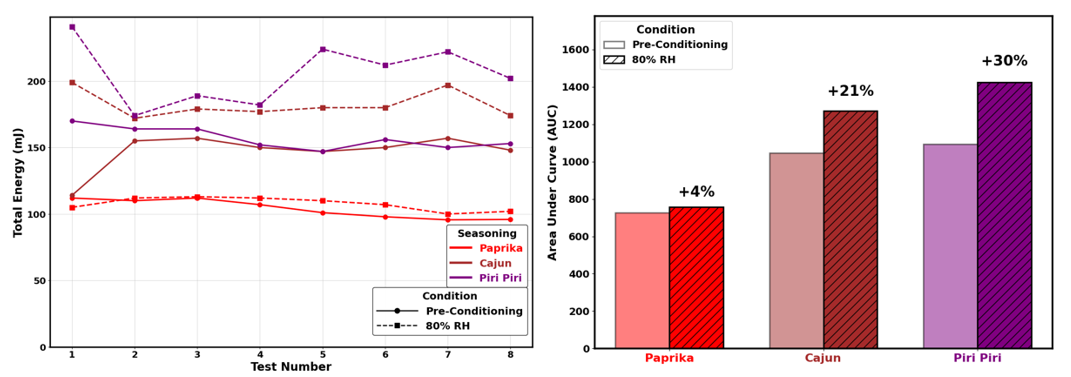

The results reveal a large difference in how each seasoning responds to the same environmental conditioning step, with total flow energy profiles differing substantially. We can quantify these differences by extracting the area under the curve, providing a single, straightforward metric for comparison. A larger area under the curve indicates that more energy was required for the powder to flow, reflecting reduced flowability.

Paprika demonstrated the highest degree of stability out of all seasonings tested, with only a 4% increase in area under the curve between the pre-conditioned and 80% relative humidity state. This suggests that Paprika is not a very hygroscopic powder. Even at high relative humidities intended to mimic tropical environments, it resisted moisture uptake, preventing the formation of extensive capillary bridges. This is ideal for processing, as it suggests it requires little to no flow aids or environmental controls to maintain optimal flowability.

In contrast, both Cajun and Piri Piri seasonings exhibited a large increase in total energy post-conditioning. Notably, the Piri Piri seasoning displayed the most pronounced increase, with a 30% increase in area under the curve. In a processing environment, this behaviour indicates a high risk of caking, equipment blockages, and downtime. Consequently, mitigation strategies are required to ensure process stability.

Summary

This study has highlighted that different seasoning blends can possess varying levels of hygroscopicity. While Paprika remained stable under humid conditions, Cajun and Piri Piri seasonings exhibited a marked increase in total energy. Understanding how specific powders react to environmental shifts is essential for predictable and efficient processing. Our expertise in powder characterisation provides the precise data required to comprehensively characterise your powder’s flow behaviour. If you want to learn more about how we can support your needs, do not hesitate to contact us.

Related Articles;

Rapid Prediction of Powder Caking, Crusting and Agglomeration

Flow to Flavour: Dynamic Powder Analysis for Optimising Seasoning Coating

The Impact of Humidity on Seasoning Powder Flowability in Global Processing

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.