In this study, we characterised the foaming behaviour of commercial alcoholic and non-alcoholic beers to identify the underlying interfacial properties governing foaming performance. Correlations can be observed between the observed foamability and foam stability through two key metrics:

In this study, we characterised the foaming behaviour of commercial alcoholic and non-alcoholic beers to identify the underlying interfacial properties governing foaming performance. Correlations can be observed between the observed foamability and foam stability through two key metrics:

- Dynamic Surface Tension at Short Surface Ages

- Interfacial Modulus

Our findings demonstrate that capturing these highly relevant interfacial properties provides essential data required for formulation optimisation, enabling targeted improvement of foaming characteristics.

The Science of Beer Foam: Formation, Stability, and the Non-Alcoholic Challenge

A beer’s foam head is much more than a visual detail; it’s a significant part of its quality. A well-formed and stable foam improves a consumer’s overall perception of the beer by creating a lubricating mouthfeel and releasing aromas. In beers, foam is formed during pouring as dissolved carbon dioxide or nitrogen nucleates into bubbles. This process is driven by the sudden release of pressure and agitation of the pour, which traps gas and creates the initial bubble structure.

However, once a foam is formed, it must also be stable. A foam made of a simple, low viscosity liquid without any stabilising ingredients would collapse almost instantly. Therefore, beer foam is stabilised by a complex suite of surface-active molecules derived from its core ingredients. These key molecules, primarily proteins and peptides, rapidly migrate to and adsorb at newly created air-liquid interfaces of bubbles to stabilise them.

The rise of high-quality non-alcoholic beers presents a new formulation challenge. The removal of ethanol has complex effects on the interfacial and foaming properties of non-alcoholic beers. Ensuring a deeper understanding of their unique interfacial properties is therefore essential to optimise formulations for desirable foaming characteristics.

Let’s discuss your interfacial analysis requirements

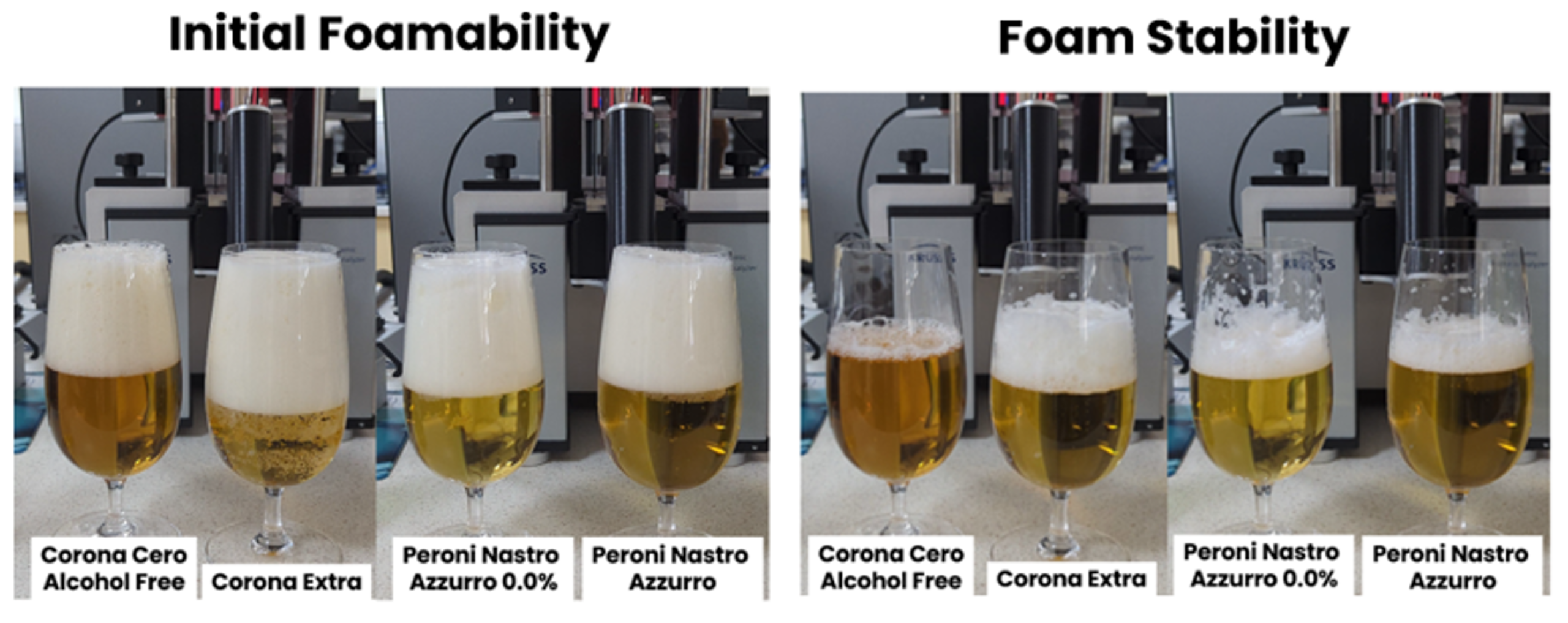

In this study, we characterised alcoholic and non-alcoholic beers from two key brands: Peroni and Corona. Before any measurements, all samples were degassed by gently stirring with a magnetic stirrer for an extended period.

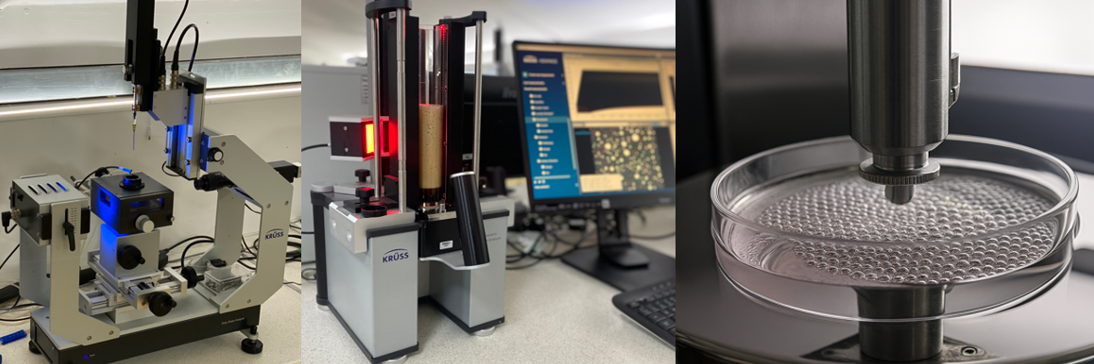

The investigation focused on three key analytical techniques:

An Interfacial Assessment of Beer Foam Stability and Foamability

Foam Analysis

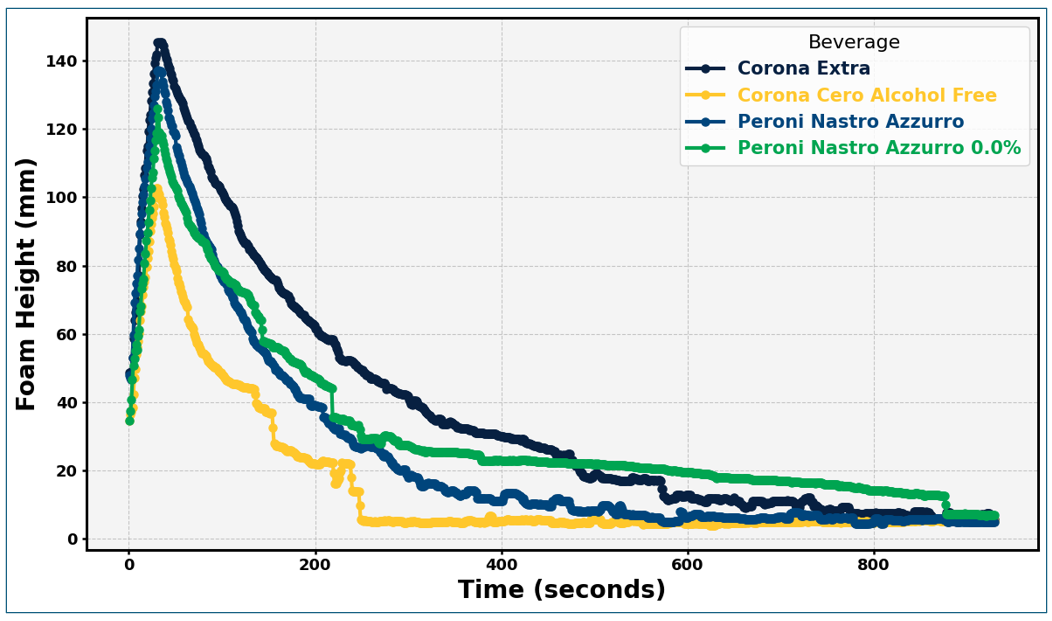

Foam analysis was conducted using a dynamic foam analyser to provide a detailed, time-resolved analysis of key foaming characteristics. Metrics obtained include bubble count, bubble size distribution, foamability, and foam stability over time. In this study, the focus is on foamability and foam stability of the beers tested.

Given that alcohol variants exhibit superior foamability and stability, a primary optimisation goal for non-alcoholic alternatives is to match these benchmark foam characteristics as closely as possible.

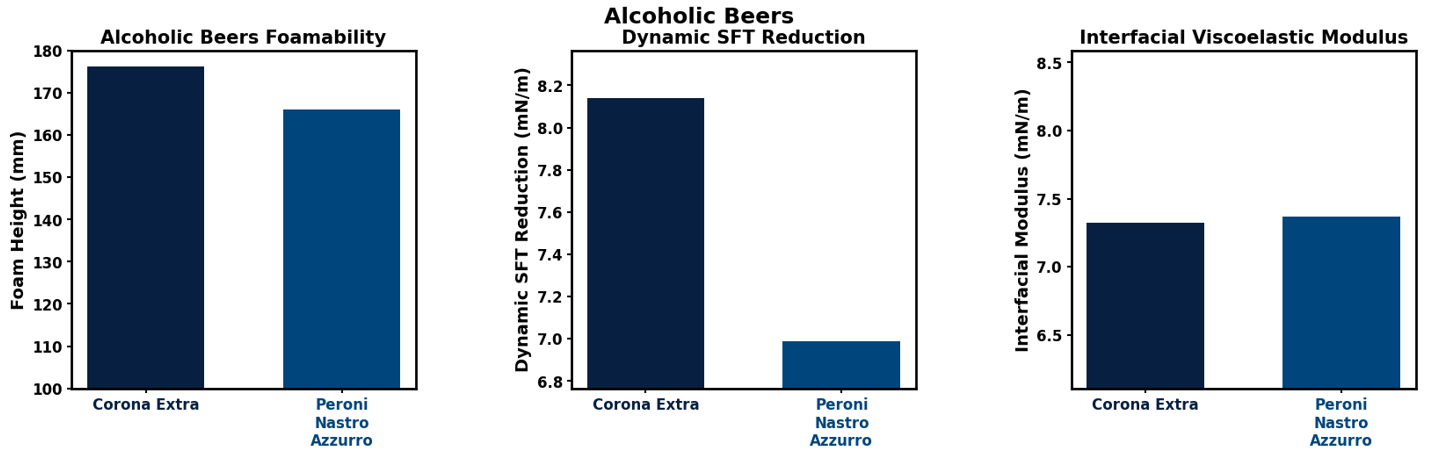

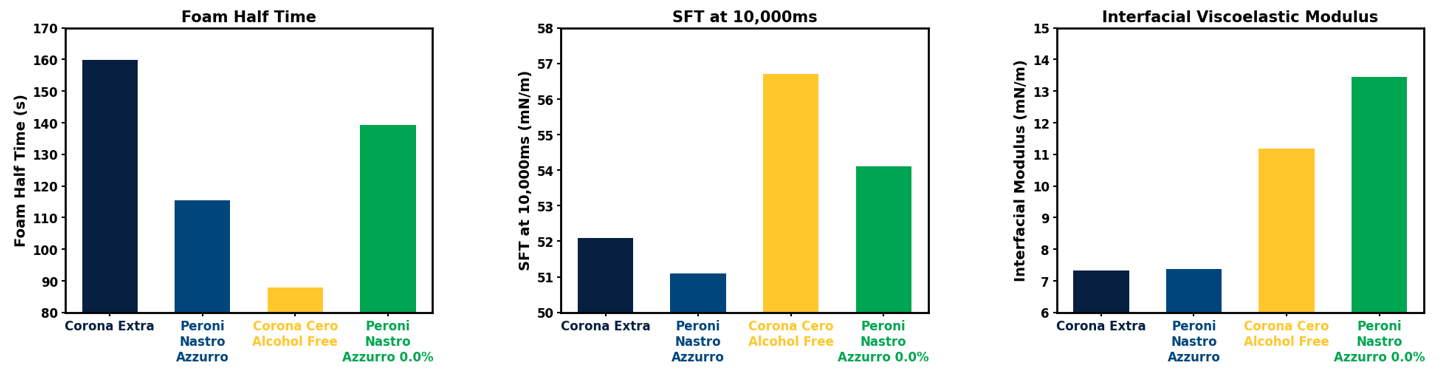

Among the alcoholic samples, Corona possessed greater foamability and foam stability. Specifically, a maximum foam height of 145mm was achieved compared to Peroni at 137mm. For foam stability, Corona exhibited a foam half-time of 160 seconds, versus 115 seconds for Peroni.

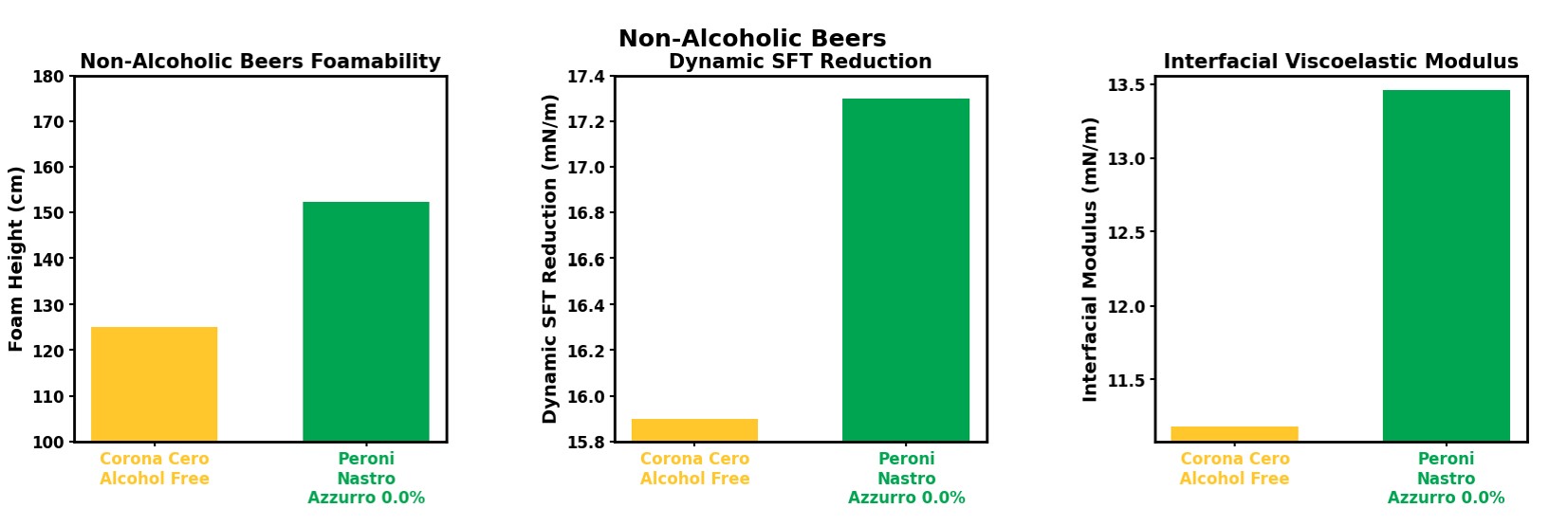

In the non-alcoholic category, this trend was reversed. The Peroni variant performed significantly better, with foam characteristics that closely matched those of its alcoholic counterpart. In contrast, the non-alcoholic Corona’s foamability was comparatively poor. Interestingly, the non-alcoholic Peroni exhibited greater foam stability than the alcoholic Peroni.

While benchmarking foaming behaviour is a vital first step, it’s equally important to understand the underlying physical properties driving such behaviours. We provide a suite of interfacial characterisation services specifically designed to analyse properties that can govern foaming behaviour, giving you a better understanding of why your formulations may perform the way they do.

Interfacial Modulus

At the Centre for Industrial Rheology, we have extensive expertise in dilatational interfacial rheology. We utilise oscillating pendant drop methods to quantify the viscoelastic properties of an interface by probing how it responds as it is expanded and contracted.

Viscoelasticity at the interface is an extremely important property concerning foam formation and stability. It is quantified by the interfacial viscoelastic modulus, which describes the interface’s overall resistance to deformation. For a bubble, an interface with a high viscoelastic modulus creates a resilient ‘skin’. The elastic component contributes to resistance to deformation, while the viscous component allows the interface to dissipate energy when stretched or compressed effectively.

It is important to note, however, that viscoelasticity at the interface must be balanced against other properties such as surface tension. A high surface tension can be a dominant, destabilising force that accelerates drainage and bubble collapse.

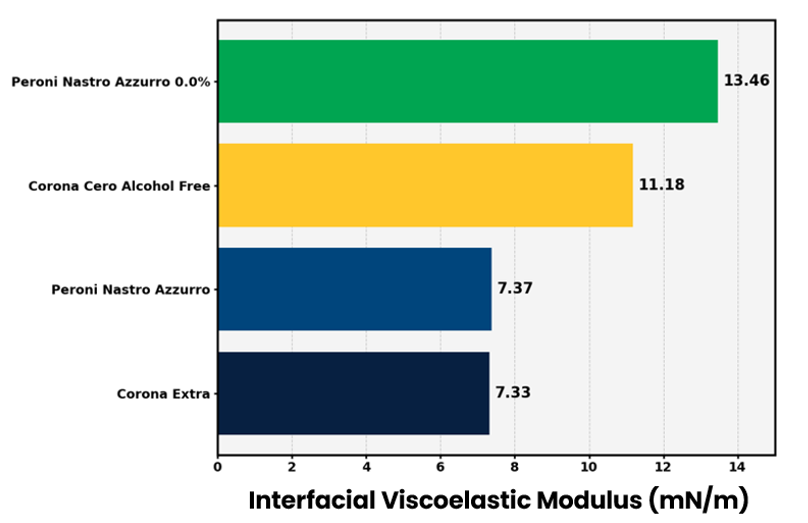

The results show that the alcoholic variants exhibit a lower interfacial viscoelastic modulus compared to their non-alcoholic counterparts. This behaviour is expected, as ethanol competes with foam-stabilising proteins for adsorption at the interface. This competition disrupts the formation of a strong, elastic protein network, resulting in a weaker interface and a lower modulus. Alcoholic variants showed no significant differentiation in interfacial viscoelastic modulus. However, for the non-alcoholic variants, Peroni exhibited a higher interfacial viscoelastic modulus than Corona.

Dynamic Surface Tension at Short Surface Ages

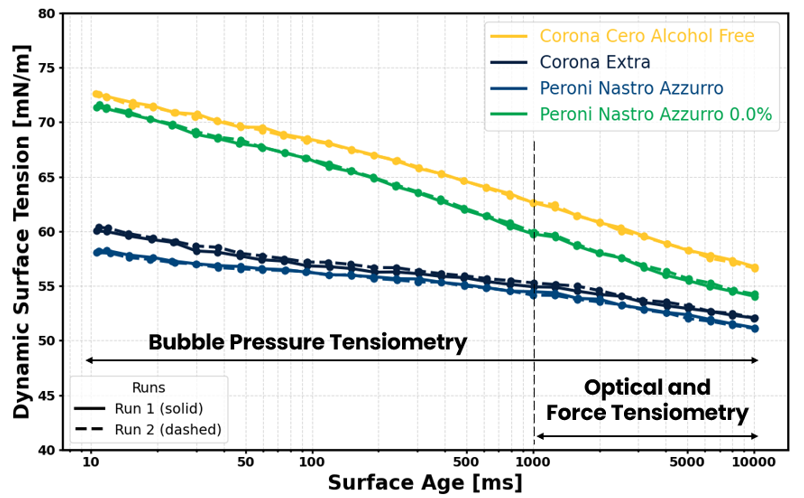

In applications such as foaming, new interfaces are created in timescales of milliseconds. Traditional surface tension measurements, such as optical and force tensiometry, typically capture data only from one second onward. This means they fail to probe the most relevant, short timescales that govern initial foam formation.

We take characterisation further by utilising bubble pressure tensiometry. This technique allows us to measure surface tension from surface ages as short as 5 milliseconds, providing insights at timescales far more relevant to foam formation processes. The key advantage of this approach is the ability to assess the kinetics of surface-active molecules. This is probed by how quickly surface tension is reduced, giving insights into how quickly surface-active molecules diffuse and adsorb at newly formed interfaces.

The dynamic surface tension results reveal fundamental differences between the alcoholic and non-alcoholic variants, driven primarily by their distinct solvent compositions. As expected, the water-based non-alcoholic samples start with a high surface tension, close to that of water. In contrast, the alcoholic variants contain ethanol, which is itself a highly surface-active cosolvent, resulting in a lower bulk surface tension. For both variants, their performance is largely governed by how quickly surface-active molecules, such as proteins, can diffuse to newly formed interfaces to lower surface tension.

When comparing alcoholic variants, the Corona sample showed greater surface tension reduction compared to Peroni. However, for non-alcoholic variants, this trend is clearly reversed, with the Peroni sample exhibiting a greater surface tension reduction than Corona.

Correlation of Interfacial Properties with Foam Performance

Having characterised dynamic surface tension and interfacial modulus, we can now investigate the correlations present between these properties on foamability and foam stability.

Foamability

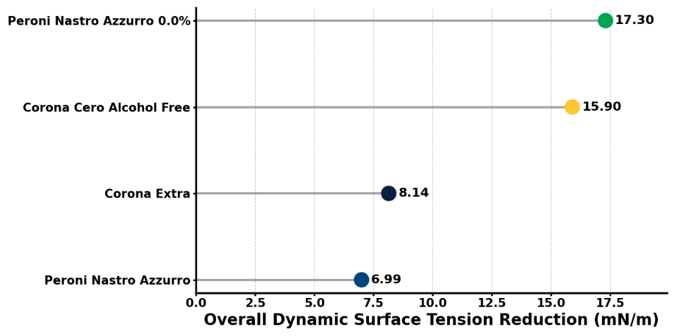

Analysis of interfacial properties revealed significant differences between alcoholic and non-alcoholic beverage variants. This is a divergence that was expected, given their different solvent compositions. For instance, the non-alcoholic variants are aqueous systems with an initial surface tension close to that of water, whereas the alcoholic variants begin with a much lower surface tension due to the presence of ethanol. Consequently, a direct comparison, such as the magnitude of surface tension reduction, would be misleading, as the aqueous samples, starting from a much higher baseline, naturally exhibit a much greater magnitude of reduction.

This fundamental difference in their interfacial properties necessitates separate comparisons and graph scaling. The correlations between foamability and the measured interfacial properties are presented in Figure 9.

Among the alcoholic variants, the Corona sample exhibited superior foamability. While the interfacial modulus values between the Corona and Peroni samples were not significantly different, the Corona sample exhibited a greater reduction in dynamic surface tension. This difference in dynamic surface tension is a potentially explanatory factor for its enhanced foamability.

For the non-alcoholic variants, Peroni 0.0% demonstrated excellent foamability, with performance matching closely to that of its alcoholic counterpart. The Peroni 0% sample exhibited both a greater interfacial modulus and a greater dynamic surface tension reduction. These properties, in combination, can explain the superior foaming behaviour relative to the Corona 0.0%.

Foam Stability

While the previous analysis, focusing on foamability and its relation to dynamic surface tension reduction and interfacial modulus, benefited from a split-sample view, for comparing foam stability, we now focus on equilibrium surface tension values. As these are absolute values, they provide a common baseline, allowing all four samples to be analysed on the same graph.

The results demonstrate a complex interplay between interfacial properties and foam stability. A direct comparison between the Peroni variants reveals the importance of interfacial viscoelastic modulus; the 0.0% sample, despite a higher surface tension, exhibited a substantially greater modulus and correspondingly longer half-time than its alcoholic counterpart.

Conversely, the Corona Cero 0.0% sample highlights the detrimental impact of high surface tension. While its interfacial modulus was higher than its alcoholic counterparts, it also possessed the highest surface tension in the study. This high surface tension could be acting as a dominant factor, overwhelming effects from the increased modulus, and resulting in the lowest foam stability observed.

Summary

This case study has highlighted that while benchmarking foam performance can be extremely useful, it is only the first step to truly characterising foams. While a foam analyser can tell you what is happening, it cannot tell you why. The true drivers of foamability and stability are their underlying interfacial properties. As this study showed, foam performance is not a simple, single-property issue, but rather a complex interplay between competing factors. The results obtained show that:

- A high interfacial modulus is beneficial, but its positive effect can be diminished by a high surface tension, leading to poor stability.

- Greater dynamic surface tension reduction strongly promotes foamability, but it must be balanced with modulus and absolute surface tension values to ensure stability.

By measuring these key interfacial properties, from millisecond timescale dynamic surface tension to interfacial modulus, a more complete picture of competing mechanisms is obtained. This helps to provide a clear, data-driven roadmap for targeted and effective foam formulation.

Our full suite of characterisation services, coupled with our extensive expertise, provides you with essential insights required to truly understand your formulations. If you want to optimise your foam formulations and innovate past the competition, do not hesitate to contact us.

Related Articles;

Foam Stability Prediction: Interfacial Rheology Measurements

Foam tribology and structure: Creating silky, smooth and creamy

Brush, Foam, Repeat: Not without Interfacial Rheology!

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.