Many products, such as laundry detergents, contain surfactants. When characterising these products, obtaining their dynamic surface tension profiles from surface ages as short as 5 milliseconds provides far more insights than a static or equilibrated value.

Many products, such as laundry detergents, contain surfactants. When characterising these products, obtaining their dynamic surface tension profiles from surface ages as short as 5 milliseconds provides far more insights than a static or equilibrated value.

A primary function of a surfactant in laundry detergents is to reduce surface tension to aid in wetting and penetration of fabrics. However, to be effective in a process such as a washing cycle, surfactant molecules must rapidly migrate to and adsorb at newly created interfaces, such as the water-soil interface.

This is where optical and force tensiometer methods fall short, as they only capture surface tension values from approximately one second onwards. For dynamic processes involving foaming or agitation in a washing machine, what truly matters is surfactant diffusion and adsorption kinetics. This is how quickly surfactants act to reduce surface tension in timescales of milliseconds.

This is where optical and force tensiometer methods fall short, as they only capture surface tension values from approximately one second onwards. For dynamic processes involving foaming or agitation in a washing machine, what truly matters is surfactant diffusion and adsorption kinetics. This is how quickly surfactants act to reduce surface tension in timescales of milliseconds.

Discuss the dynamic surface tension profiles of your materials

Contact us

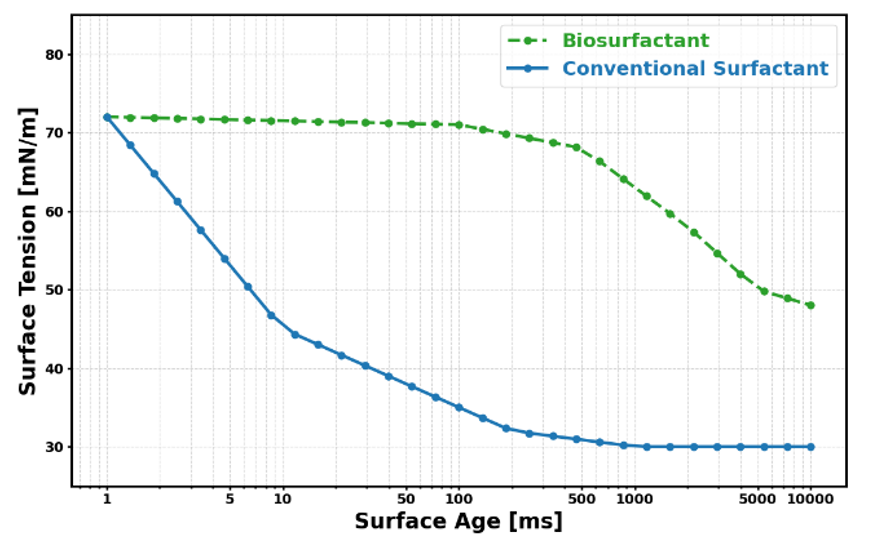

As the industry seeks sustainable ingredients, biosurfactants are emerging as a promising alternative to conventional surfactants. However, for them to be commercially viable, their performance must be directly comparable.

We provide dynamic surface tension measurements at short surface ages as a key tool for screening this efficacy, benchmarking biosurfactant kinetics against synthetic surfactants. Utilisation of such data will no doubt be essential to formulate a successful, high-performance laundry detergent containing biosurfactants.

The Rise of Biosurfactants

Commercially used surfactants within laundry detergents are typically synthetic and derived from petrochemical feedstocks. In contrast, biosurfactants are derived from renewable feedstocks. Their key advantages are that they possess high biodegradability and low toxicity, and many can withstand extreme temperatures and pH levels that conventional surfactants may fail to withstand. However, a key barrier to the adoption of biosurfactants is their significantly higher manufacturing cost. Despite this, the market for biosurfactants is growing rapidly, driven by stricter environmental regulations and consumer demand for sustainable products.

Beyond this, their practical viability as substitutes is contingent upon closing a potential performance gap with their synthetic counterparts. A conceptual dynamic surface tension profile is shown below in Figure 1, revealing how a biosurfactant’s surface tension reduction may differ from that of a conventional surfactant.

Figure 1 highlights that biosurfactants can possess significantly slower adsorption kinetics, which will translate to reduced cleaning efficacy for laundry detergents. Established detergent formulations rely heavily on the rapid action of synthetic surfactants such as linear alkylbenzene sulfonates (LAS) and fatty alcohol ether sulphates (FAES). As the industry seeks to integrate more sustainable biosurfactants such as mannosylerythritol lipids (MEL), overcoming their slower adsorption kinetics is essential.

A hybrid approach combining biosurfactants with low concentrations of synthetic surfactants could be a feasible transitional strategy. Measuring the dynamic surface tension profiles of such mixtures is therefore fundamental, offering a rapid screening method to identify synergistic blends that optimise adsorption kinetics to ensure efficacy comparable to established detergents.

Dynamic Surface Tension of Laundry Detergents

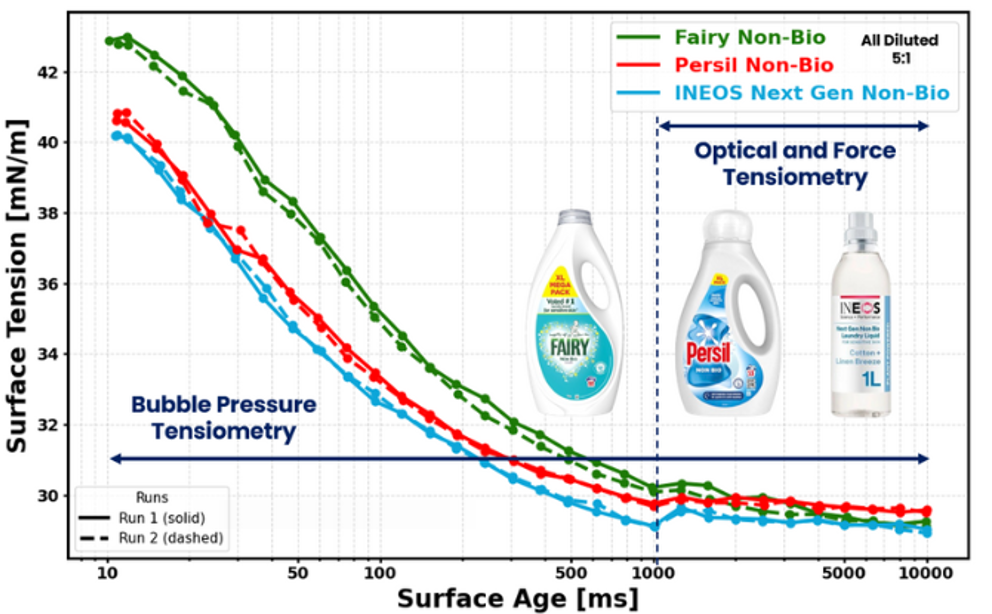

We tested three market-leading laundry detergents to demonstrate the value of dynamic surface tension measurements from surface ages as short as 5ms for benchmarking product performance.

The results showed that INEOS Next Gen non-bio exhibited both the lowest surface tension and the most significant drop across the surface age range tested. While the quantitative differences between samples are small, this optimisation in dynamic surface tension can lead to greater product performance through better wetting of fabrics and thus cleaning.

Importantly, the data highlights significant surface tension reduction at surface ages below 1000ms, a range not captured by optical or force tensiometry. After 1000ms, values can be seen to stabilise, showing little further decrease. Relying solely on these equilibrated values can be misleading for formulation development, as it fails to account for these crucial early-stage surfactant kinetics.

Summary

While equilibrated surface tension values provide a useful comparison of behaviour between samples, this value represents a stable state that a system reaches after surfactants have had ample time to migrate to newly formed interfaces. This metric fails to capture the initial kinetics of surfactant adsorption, which can be essential for performance in a wash cycle. Dynamic surface tension data at millisecond timescales can help bridge the gap between a formulation’s chemistry and its real-world cleaning efficacy.

As the industry transitions to more sustainable biosurfactants, optimising their adsorption kinetics is crucial for addressing any performance gaps and ensuring they can effectively replace traditional synthetic surfactants. If you would like to learn more about how our dynamic surface tension analysis services can assist you in benchmarking and optimising high-performance, sustainable detergent formulations, please contact us. Additionally, if you are interested in the intricacies of performance, check out our foam analysis of laundry detergents, which highlights the impact of formulation and water hardness on foamability.

Related Articles;

Using Dynamic Surface Tension to Understand Household Surface Spray Performance

Softness, Stability and Spectroscopy: Uncovering Fabric Conditioner Structure

Understanding the Effects of Temperature on Surface Tension

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.