We provide expert material characterisation and sample testing services for a range of critical material properties for:

- Suspensions and emulsions

- Polymer solutions, gels and hydrocolloids

- Waxes and resins

- Powders and melts

…and a host of other materials.

Our rapid turnaround service is backed up with all the support and advice you need to ensure you:

- Understand the test methods performed and the metrics obtained

- Understand how the results gathered relate to, or predict, product performance

- Can confidently discuss the work performed with your colleagues, associates, and management

We’re dedicated to helping you interpret the data and translate it into meaningful decisions for your applications

Get a quote and turnaround time

Rotational Rheology Profiling

Rheological profiles offer powerful insights into the processing, storage, handling, and performance properties of a wide range of liquids and semisolids. The commonly-measured properties include:

- Viscosity: The resistance to flow of your product across a range of conditions

- Yield stress: The stress necessary to initiate the flow of your product

- Thixotropy: The rate and extent of breakdown on shearing and recovery at rest

- Viscoelasticity: Storage Modulus and Loss Modulus, Tan Delta and Normal Stress

- Creep tests: Creep and recovery for zero-shear viscosity and compliance measurements

We can also measure samples across a range of temperatures. Measurements can be performed from -45°C to +450°C

Rheo-Impedance Spectroscopy

Rheo-IS combines powerful rheological profiling, which studies the viscosity and viscoelasticity of materials, with impedance spectroscopy, which probes microstructure through how materials resist and “react against” an applied alternating electrical signal across a range of frequencies.

- See how shear and temperature influence impedance

- Detect subtle structural changes

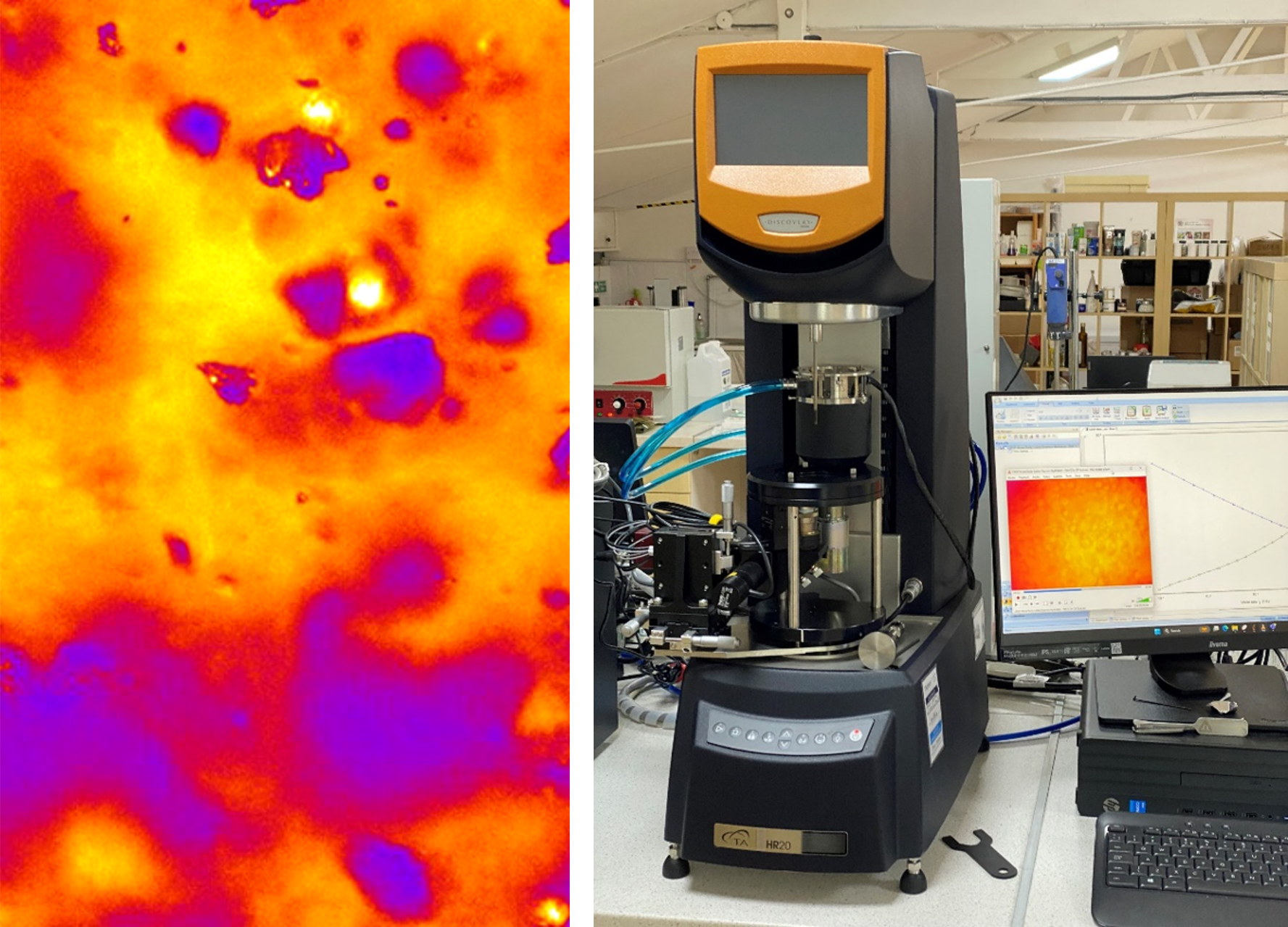

Rheo-Microscopy

Using a combination of rheological tests and microscopy imaging, we can look at the material structure under shear deformation. This enables us to see and predict the response from the material under storage conditions.

Using a combination of rheological tests and microscopy imaging, we can look at the material structure under shear deformation. This enables us to see and predict the response from the material under storage conditions.

- Simultaneous measurement and imaging

- Capture crystallisation, melt, dissolution, and erosion

- Microstructure under shear and after shear

- Counter-rotation to capture a stagnation plane

- Cross polarisation

- Fluorescence

Dynamic Mechanical Analysis

Dynamic Mechanical Analysis (DMA) is a subset of thermal analysis techniques for characterising viscoelastic properties as a function of temperature or frequency. DMA can explore properties such as the glass transition, damping properties, relaxation properties and decomposition under specific environmental conditions or phase changes such as melt, curing or crystallisation

Viscosity Measurement

We perform an extensive range of liquid viscosity measurements on a variety of sample types. Certificates of analysis include values in centiPoise or Pascal seconds, for Dynamic Viscosity, and centiStokes or mm^2/s for Kinematic Viscosity

We perform an extensive range of liquid viscosity measurements on a variety of sample types. Certificates of analysis include values in centiPoise or Pascal seconds, for Dynamic Viscosity, and centiStokes or mm^2/s for Kinematic Viscosity

Tests available include:

- Viscosity measurements across a range of shear rates for pump specification, pipe flow calculations, spreading, coating, and application

- Viscosity at low stresses: For predicting storage stability and settling, sagging, and slumping

- Viscosity/temperature profiles: For process, pumping, handling predictions

- Brookfield viscosity: Simple spindle viscometer measurements

Capillary Rheology

Our capillary rheometer enables the measurement of shear viscosity and extensional viscosity, extrusion properties and mobility from ambient temperature up to 400°C.

- Ultra-high shear rates achieved

- High temperature

- Extensional viscosity

Interfacial and Surface Characterisation

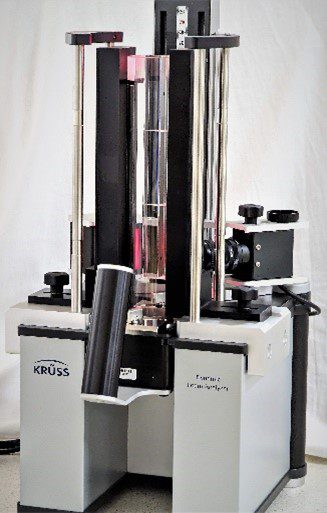

Drop Shape Analysis

We perform a range of surface and interfacial testing, including:

- Contact Angle, including advancing, receding and equilibrium contact angle, and dynamic wetting

- Surface Tension (at an air/liquid interface) and Interfacial Tension (at a liquid/liquid interface)

- Surface Free Energy characterisation of substrates and solid materials

- Powder wettability with Washburn Cell

- Interfacial rheology: Measuring the viscoelastic moduli and viscosity of the liquid/liquid interface in an emulsion or the gas/liquid interface in a foam

Bubble Pressure Tensiometry

Bubble pressure tensiometry bridges the gap between traditional surface tension measurements and the dynamic behaviour at short timescales

- Short Surface Age measurements

- Surface tension as a function of temperature

Dynamic Foam Analysis

Dynamic Foam Analysis

Dynamic Foam Analysis entails creating a foam under defined conditions then quantifying foamability, foam stability, and foam structure.

- Foamability

- Liquid drainage

- Foam height and volume

- Direct imaging and quantification of bubble size distribution

- Foam stability

- Foam half-life

Dynamic Light Scattering and Zeta Potential

The addition of DLS/Zeta Potential to our rheology and interfacial characterisation techniques delivers a robust and comprehensive characterisation of structural properties on the nano and micro scale

With these techniques, we can characterise:

- Particle size and size distribution, from 1nm to 10µm

- Stability of suspensions and emulsions as a function of temperature, pH, and ionic environment

- Aggregation and agglomeration of particles, emulsified droplets, proteins, and other macromolecules

- Colloidal characterisations

- Iso-electric point and Debye Length

Learn more

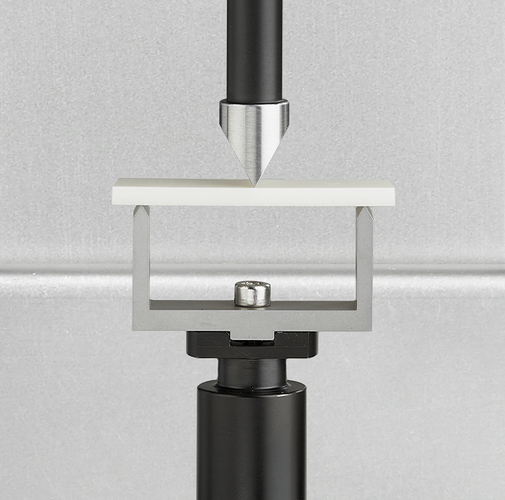

Tribology, Friction and Lubricity Profiling

Tribology is an exciting, relatively new method for the food, cosmetics, and pharmaceuticals industry. Tribology involves taking measurements of the lubricating qualities of products in contact with a range of soft surfaces to predict the interactions of materials with biological structures such as the skin, mucous membranes, tongue, or palate.

We have also developed methods to consider the impact of salivary proteins, such as mucin, on lubrication in the oral cavity. Measurements include;

- Soft tribology and Stribeck curve generation

- Coefficient of friction

Static limiting friction (stiction) and dynamic (kinetic) friction Learn more

Powder Flow and Powder Rheology

We provide a range of powder flowability measurements and related characterisations for anybody looking to handle bulk solids, perform hopper design, or fill and transport powders. Tests include:

We provide a range of powder flowability measurements and related characterisations for anybody looking to handle bulk solids, perform hopper design, or fill and transport powders. Tests include:

- Shear cell measurements for cohesion, angle of internal friction, and flow function

- Wall friction measurements

- Compaction, consolidation and bulk density measurements

- Aeration and permeability

- Dynamic powder rheology measurements for basic flow energy and specific energy

- Sticky point and elastic behaviour

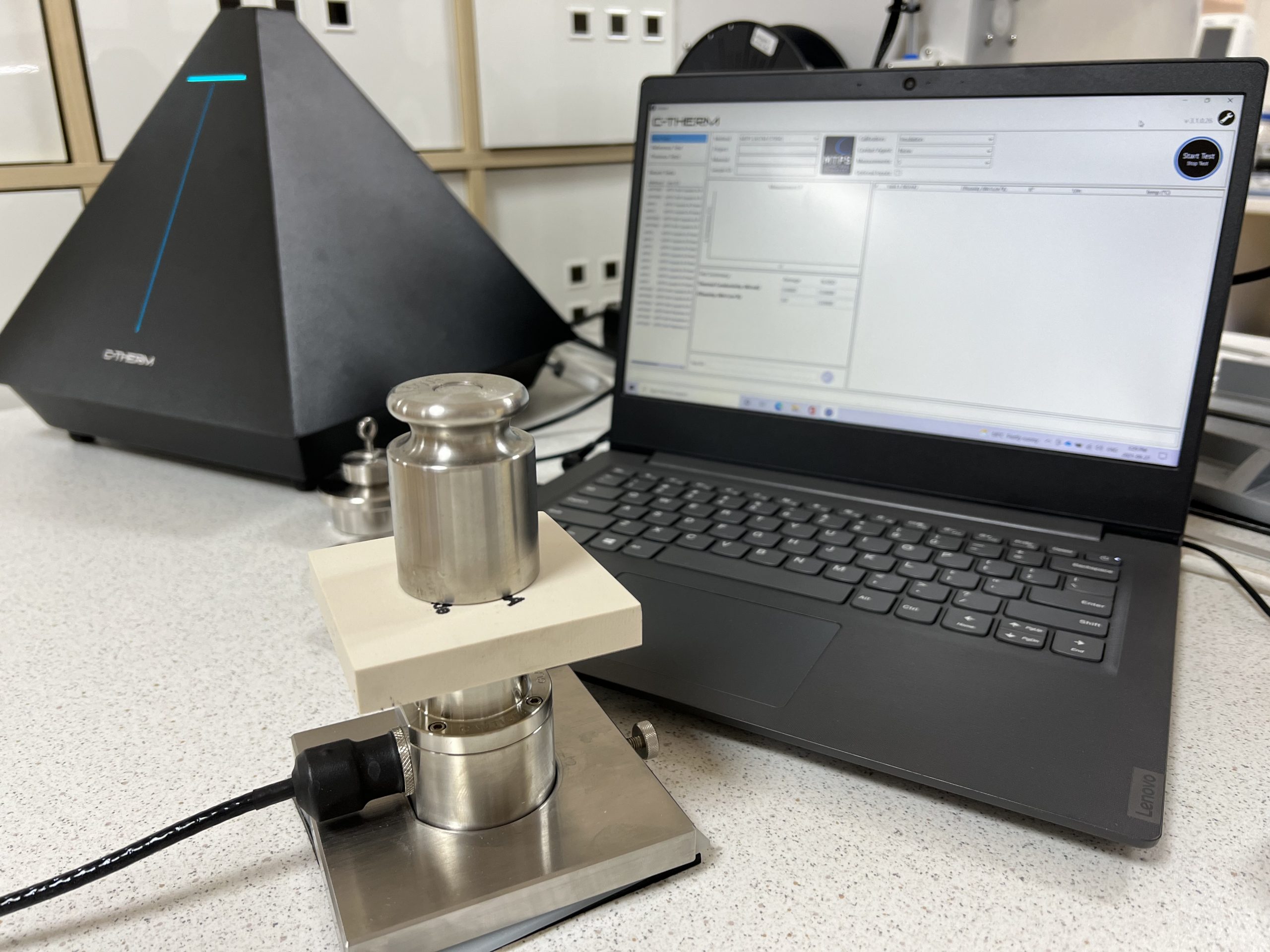

Thermal Conductivity, Effusivity, and Diffusivity

We perform thermal conductivity, thermal effusivity and specific heat capacity measurements of solids, powders, pastes and liquids.

Measurements can be performed across a range of temperatures from sub-zero to 200 Celcius.

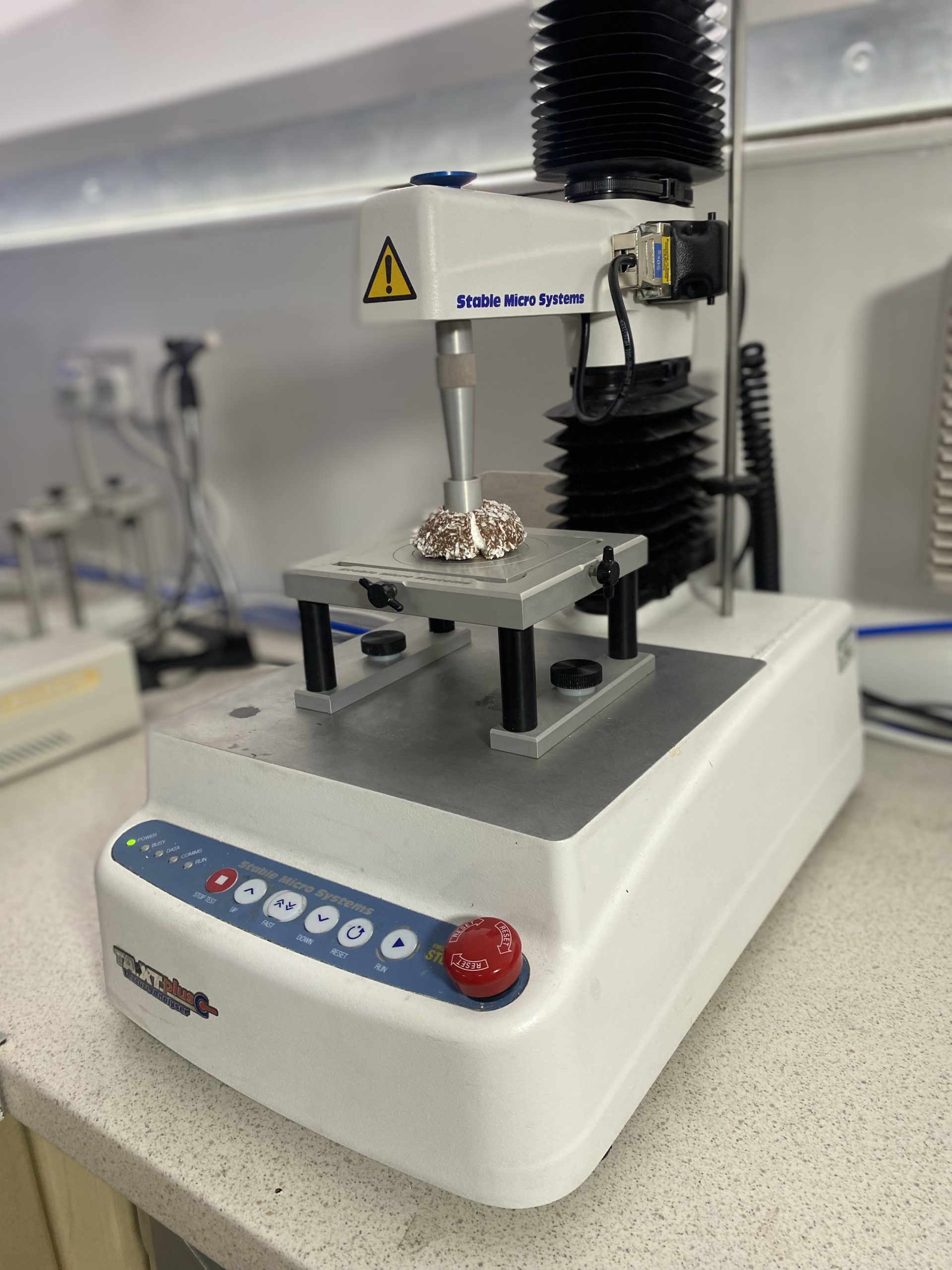

Texture Analysis and Texture Profile Analysis

We have a range of equipment and probes for performing a variety of texture tests and Texture Profile Analysis (TPA) on foods and other products, including

We have a range of equipment and probes for performing a variety of texture tests and Texture Profile Analysis (TPA) on foods and other products, including

- Compression and back extrusion for gel strength measurements and viscous behaviour

- Cutting and bite force

- Syringe force and extrusion force measurements

- Acoustic envelope capture for crispiness predictions

- Pull-off measures for tack and adhesion testing

- Three-point bending

- Puncture strength

Learn more

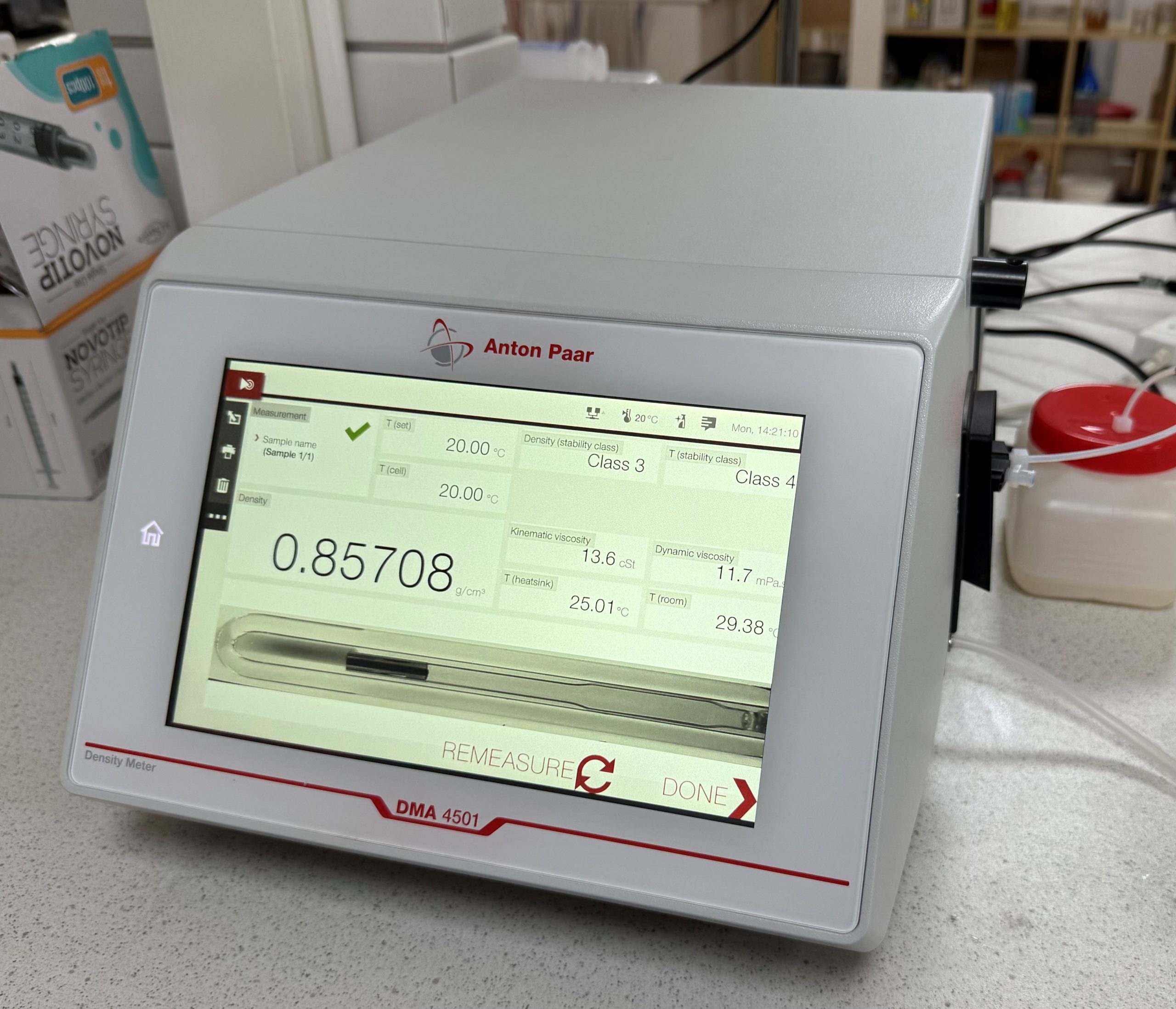

Density Measurements

Precision analysis available across a broad temperature range (0°C to 100°C), even for samples as small as 1 mL, we’re equipped to meet the most challenging demands in research and quality control

- Pulsed excitation method, compliant with international standards such as ASTM (D4052, D5002), DIN (51757), ISO (2811-3, 12185), and pharmacopoeia standards including Ph. Eur. 2.2.5 and USP 841

- Units of g/cm³, kg/m³, g/ml, and lb/gal

- Enables establishment of kinematic viscosity values for a wide range of liquids, including fuels, lubricants, foods and drinks, pharmaceutical solutions, and personal care products

Learn more

Optical Microscopy

Brightfield optical microscopy with phase contrast and cross-polarisation

Sample Conditioning

With our extensive sample conditioning capabilities, we can operate autonomously, so all our customers need to do is send their samples

- Ovens, refrigerators and freezers

- Incubators

- Ultra-Turrax homogeniser

- Overhead and magnetic mixers

- Vortexer, shaker and roller

- Fume Hood

Humidity and temperature cycling

Min and max humidity: 10% and 90%

Min and max temp: 5°C and 70°C

Moisture analysis

Utilising our Ohaus MB25 we can quantify moisture content as the percent mass lost due to evaporation of moisture (primarily water) from the sample during the heating interval.