We provide a comprehensive suite of mechanical testing services, designed specifically for applications requiring low-force, high-sensitivity measurements. Our expertise characterises the subtle mechanical behaviours of soft gels, thin films, adhesives, coatings, and other delicately structured materials, critical for predicting real-world performance and reliability.

Utilising our TA-XT Plus universal tester and texture analyser, we precisely measure mechanical responses under a wide variety of controlled deformation and failure conditions.

1. Tension, Compression, and Bending

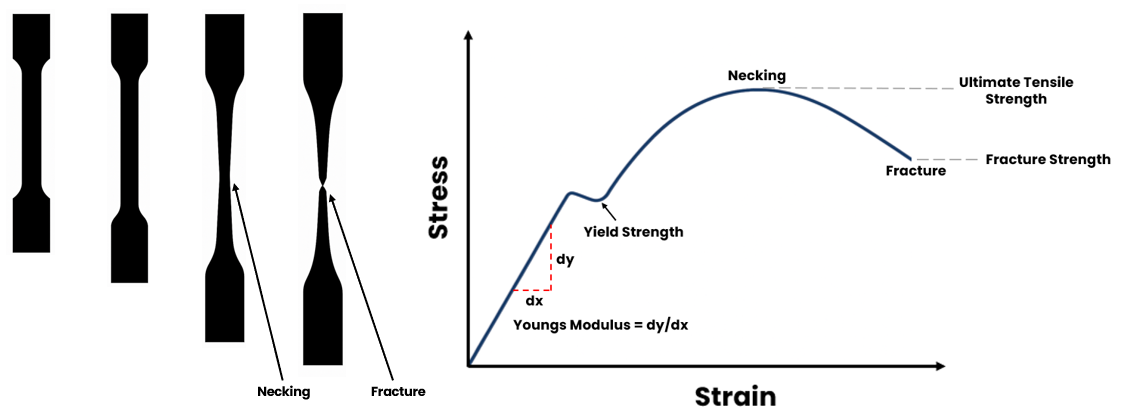

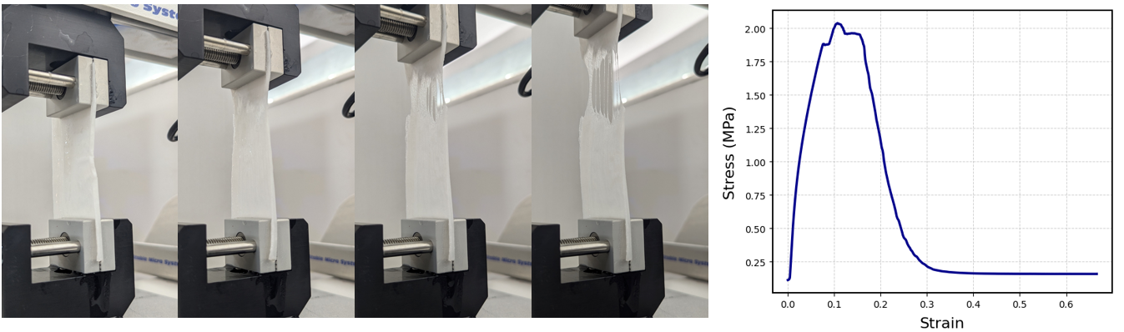

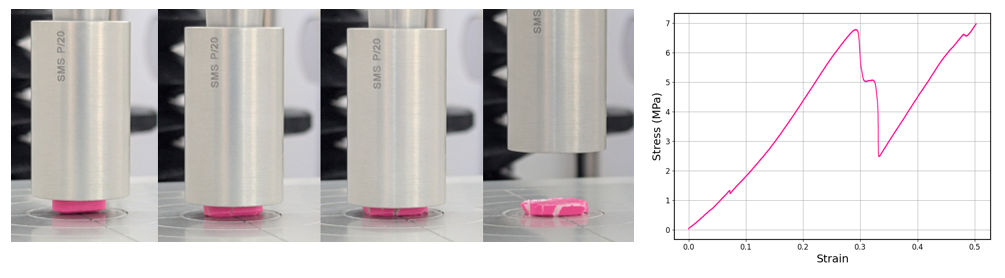

- Stress-strain characterisation

- Young’s modulus and modulus of elasticity measurements

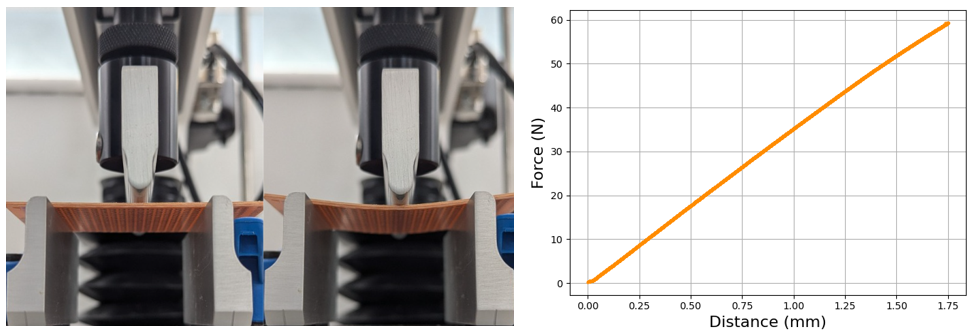

- Stiffness determination

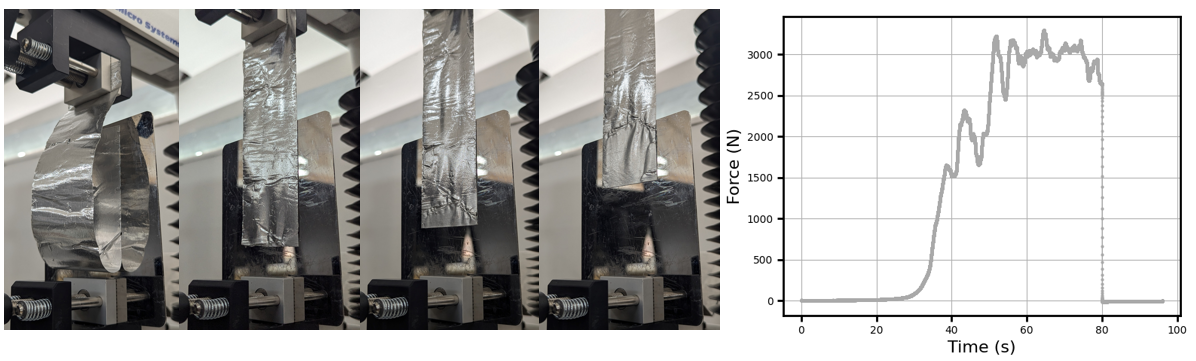

2. Fracture, Failure, and Yield Behaviour

- Yield strength analysis

- Strain hardening identification

- Fracture and failure point characterisation

- Penetration and puncture resistance

3. Adhesion and Surface Interactions

- Tack and adhesion strength

- Work of adhesion and pull-off force

- Peel resistance measurements

4. Dynamic Mechanical Behaviors

- Linear, reciprocating, and cyclic loading for fatigue testing

- Friction and wear analysis

Sensitivity and Precision at Low Forces

We measure forces as low as 0.1 g (~1 mN) with outstanding displacement resolution and control, achieving deformation rates precisely adjustable from 1 µm/s to 40 mm/s. This exceptional sensitivity allows differentiation between subtle plastic and elastic deformation regimes, providing critical insights into material behavior under gentle yet meaningful mechanical loads.

By accurately quantifying these low-force mechanical properties, we enable you to optimise your products for maximum performance, durability, and regulatory compliance.

Contact us now to discuss your specific challenges