We provide comprehensive viscosity measurements for CFD modelling as a service for anybody using packages such as Fluent, Star-CCM+, SimScale, COMSOL, Autodesk and more.

We provide comprehensive viscosity measurements for CFD modelling as a service for anybody using packages such as Fluent, Star-CCM+, SimScale, COMSOL, Autodesk and more.

The Centre for Industrial Rheology also provides several other complementary materials characterisation services including yield stress measurements, surface tension measurements, viscoelasticity measurements and thermal conductivity and curve fitting to popular models.

Whether you are looking to model flow through a heat exchanger, pump or drug delivery meducak device, within a mixing vessel or even blood pumping within the chambers of the heart, we have spent decades working with a variety of different material types and are well equipped to gather accurate viscosity and rheology data fast.

Contact our lab to arrange a virtual tour of the lab and discussion of how we can help.

Computational fluid dynamics are vital for accelerating the design and optimisation of fluid processing lines. The algorithms used to predict fluid behaviour in specific designs need real world data to be accurate, viscosity being one of the most important.

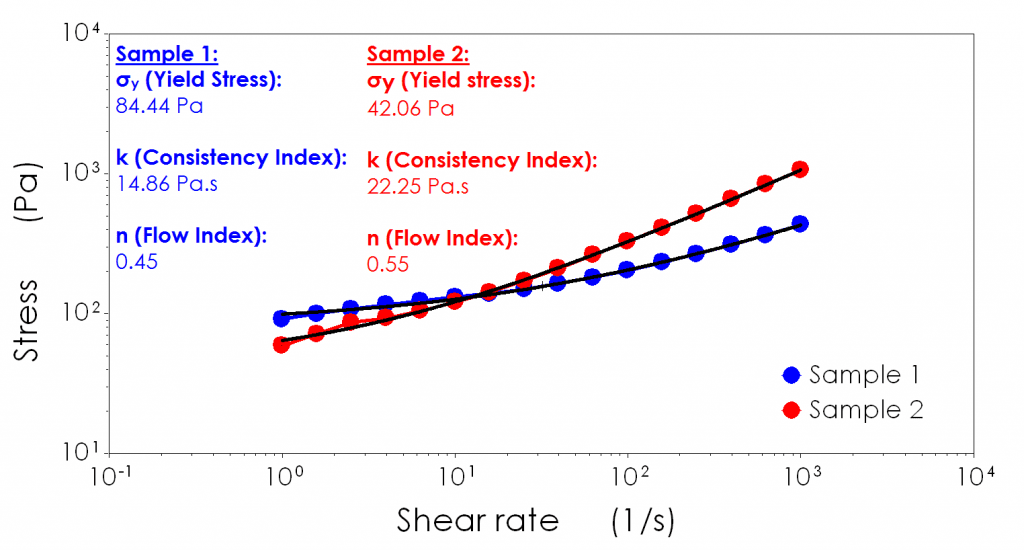

We provide viscosity measurements for both Newtonian and non-Newtonian materials and can deliver data in whatever format is most useful to you. For non-Newtonian materials, we can provide Power-law model fits including ‘k’ and ‘n’ values (also known as the ‘viscosity coefficient’ and ‘power number’ respectively) or yield stress values for Herschel-Bulkley models.

Our lab is equipped with state-of-the-art rheometers capable of measuring viscosity under very low-stress conditions. For some materials such as gels and emulsions, a plateau viscosity can be observed below critical stress. This ‘zero-shear’ viscosity or ‘cut-off’ viscosity can be useful for simplifying simulations below a critical value.

Most materials will decrease in viscosity as an increase in temperature is applied, we can provide data tracking viscosity as a function of temperature so you can optimise your processes.

Whether you are working with oils, emulsions, suspensions, polymer solutions or gels, we have a number of accessories for working with complex fluids, and decades of experience generating reliable data accurately and quickly.