Optimising dynamic surface tension profiles for each stage of a printing process is crucial for achieving the desired ink behaviour. Inks must remain stable in the printhead nozzle, jet correctly to ensure clean droplet pinch-off, and achieve effective wetting when landing on the substrate.

Optimising dynamic surface tension profiles for each stage of a printing process is crucial for achieving the desired ink behaviour. Inks must remain stable in the printhead nozzle, jet correctly to ensure clean droplet pinch-off, and achieve effective wetting when landing on the substrate.

Relying solely on static surface tension measurements means critical insights are overlooked. The key stages during printing occur in milliseconds, yet optical and force tensiometry typically only measure from surface ages of 1 second onwards.

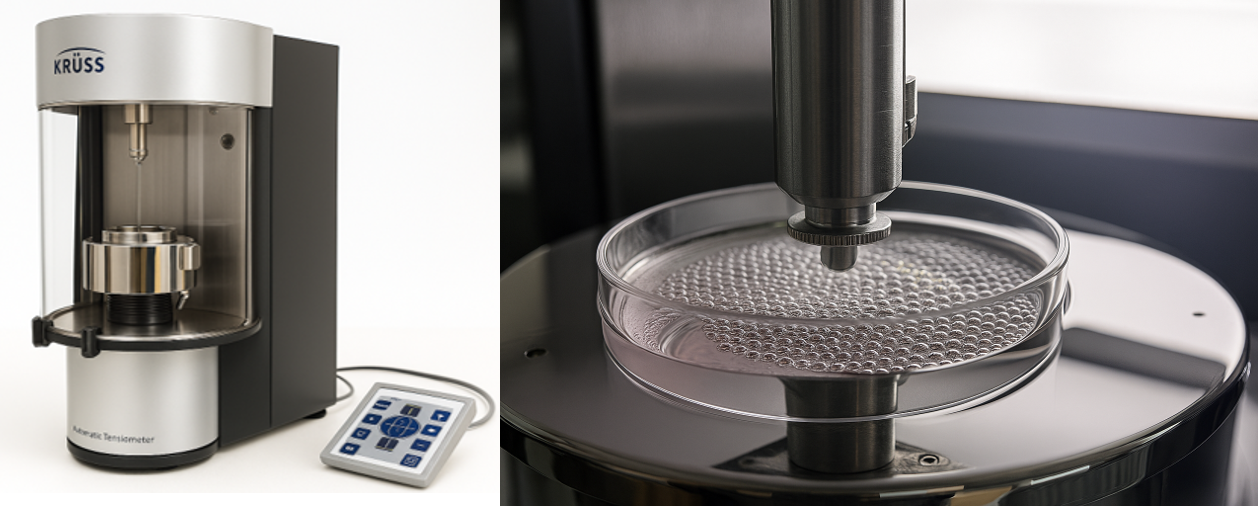

To truly understand performance under these dynamic conditions and assess surfactant kinetics, data must be captured at extremely short surface ages. We capture this behaviour using bubble pressure tensiometry, which also allows us to carry out temperature-controlled measurements.

Surfactant Behaviour of Inkjet Inks

It has been shown that surfactants with differing molecular structures can have vastly different effects on dynamic surface tension profiles [1]. For example, Head-Tail surfactants typically require higher concentrations to be effective, often exceeding their critical micelle concentration. This causes surfactants to aggregate to form micelles, slowing down their diffusion.

In contrast, Gemini surfactants are more surface-active and can function at lower concentrations before micelle formation becomes a significant factor. This allows them to migrate to newly formed interfaces rapidly, resulting in a faster surface tension reduction.

Contact us now to gain insights into ink performance

Optimisation of Dynamic Surface Tension for Inkjet Inks

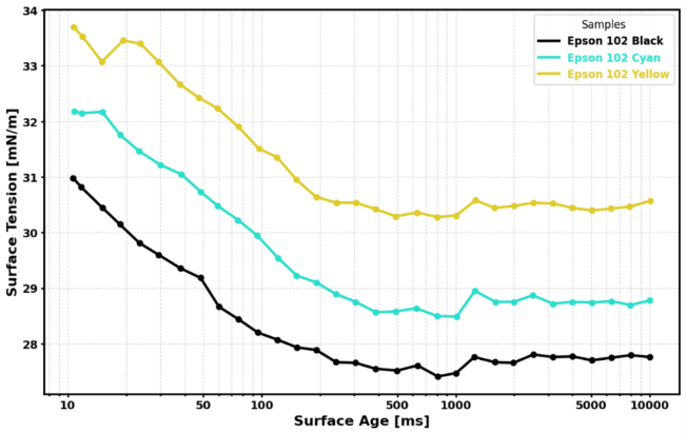

We characterised and compared the dynamic surface tension profiles of different coloured inks from the same commercial series to demonstrate the additional insights provided by bubble pressure tensiometry. The inks from this series contain Gemini surfactants.

The results show that all inks exhibit very similar dynamic surface tension profiles, distinguished by a vertical offset. The similar profiles suggest that all three inks share a common base formulation. The consistent vertical offset observed is likely due to their differing colourant types, as the black ink is pigment-based while the cyan and yellow inks are dye-based.

To interpret a dynamic surface tension profile such as this, it’s useful to consider the process in three key time regions. For an ink formulator, each of these regions presents a distinct target for optimisation:

Region 1 – In The Nozzle [5-10ms]

Initially, while the ink resides in the nozzle of the printhead, a high surface tension is desirable to stabilise the meniscus at the nozzle. This ensures it retracts cleanly after a droplet is ejected, preventing unwanted dripping.

Region 2 – Droplet Flight and Impact [20ms]

From the moment an ink droplet is ejected, it has a typical flight time of around 20 milliseconds before hitting the substrate. Within this extremely narrow timeframe, dynamic surface tension is desired to decrease rapidly, ensuring effective wetting of the substrate and clean droplet pinch-off. The surfactant’s ability to migrate quickly to newly formed surfaces is what governs this change, making its performance within this region a key challenge in ink formulation.

Region 3 – Beyond Impact

An often-overlooked aspect is how the ink behaves over much longer timescales after hitting the paper. The optical density can be influenced by the ink’s behaviour over seconds and even minutes. Developments within the inkjet industry suggest that a large, prolonged drop in surface tension within this timeframe can lead to significantly higher optical density. This large dynamic surface tension difference causes higher Laplace pressure, which drives capillary dewatering of the ink, pulling solvent into the substrate and leaving more pigment concentrated near the surface [2].

Summary

The results highlight that the performance of an inkjet ink can’t simply be defined by a single static surface tension value, but by its entire dynamic profile. The journey from the nozzle to the substrate is a story told in milliseconds, and each stage requires surface tension to be fine-tuned. By understanding and engineering this profile, ensuring stability in the nozzle, effective wetting upon impact, and controlled absorption over time, printing processes can be optimised. We also provide advanced rheological analysis for inks to aid further in formulation development. To learn more about how we can help characterise your inkjet formulations, do not hesitate to contact us.

References

[1] – Schweikart KH, Fechner B, Macholdt HT. Dynamic surface tension: a key parameter for excellent ink jet preparations. Polymer. 2005;1(1/1):1.

[2] – Boris DC, Hosmer TJ. Inkjet ink comprising dynamic surface tension agent. US patent US8690308B2. 2014 Apr 8.

Related Articles;

The Rheological Demands of Screen Printing Inks and Pastes

Understanding the Effects of Temperature on Surface Tension

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.