The Centre for Industrial Rheology is a testing laboratory providing rapid access to grease rheological measurements. Whether you are completely new to grease rheology or unsure of its potential value, we provide expert support to ensure you develop a clear understanding of the insights gained through rheological analysis.

The Centre for Industrial Rheology is a testing laboratory providing rapid access to grease rheological measurements. Whether you are completely new to grease rheology or unsure of its potential value, we provide expert support to ensure you develop a clear understanding of the insights gained through rheological analysis.

Understanding grease rheology is essential for developing effective formulations and ensuring reliable performance across applications. This article introduces the fundamental rheological concepts relevant to grease characterisation and the ISO, DIN, and ASTM standards with which we can conduct testing in accordance with.

The Value of Rheological Measurements for Greases

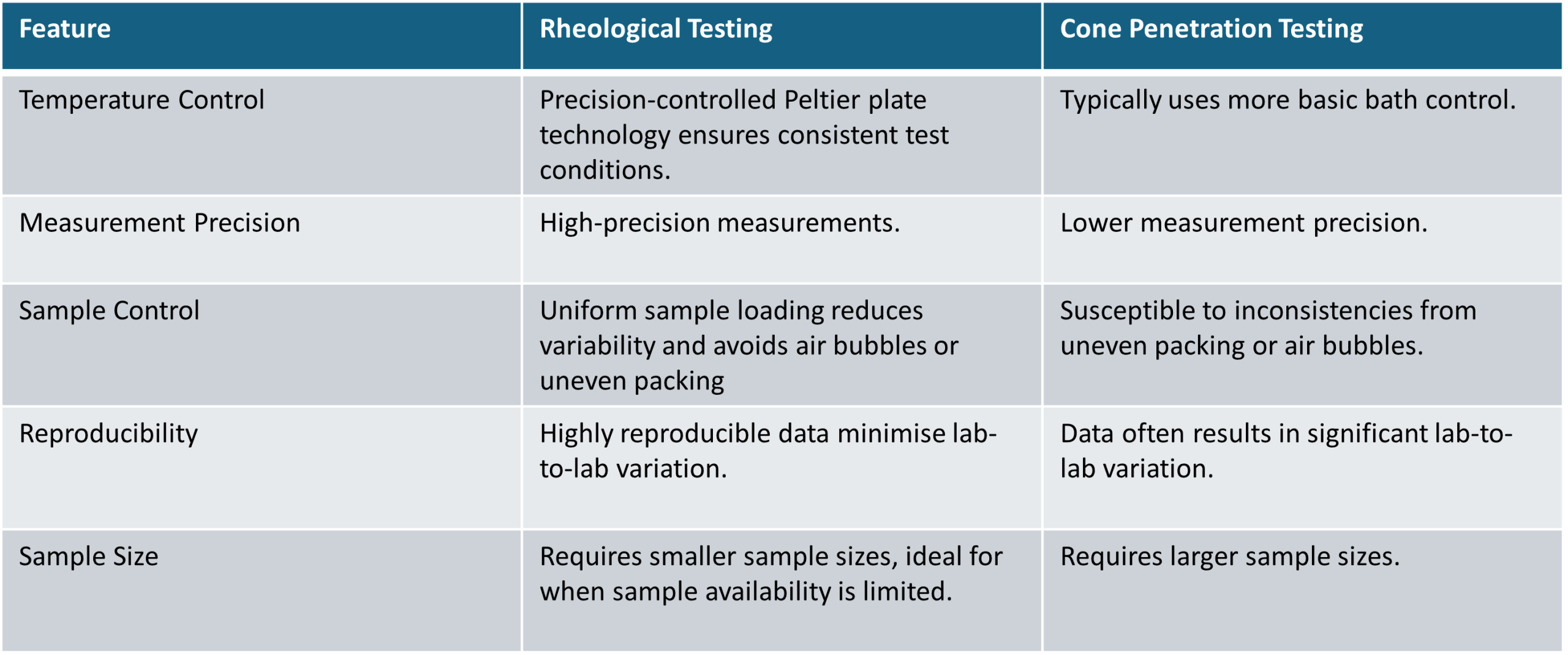

Rheology provides a host of richly nuanced material insights that go far beyond a simple, single number obtained from a cone penetration measurement. In addition to this, rheological profiling features many advantages over classic cone penetration tests, as outlined in Table 1 below.

Arrange a meeting with one of our specialists today

Oscillatory Rheological Methods for Greases

Oscillatory rheological methods are commonly used for characterising greases. These methods involve applying small oscillatory deformations to a sample. This can be thought of as gently wobbling the sample to observe how its structure responds to increasing oscillatory stress.

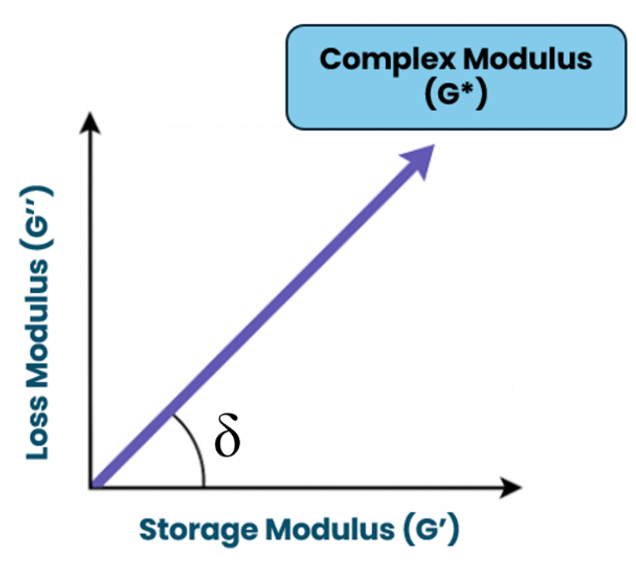

A key outcome of this method is the Complex Modulus, which describes a grease’s overall resistance to deformation, essentially, the rigidity of the grease.

It can be resolved into its in-phase and out-of-phase components to capture the solid-like and liquid-like behaviour of a grease.

Storage Modulus (G’) reflects the elastic (solid-like) response, whereas Loss Modulus (G’’) reflects the viscous (liquid-like) response.

Together, G’ and G’’ provide insights into the solid-like and liquid-like components of a grease. Is the grease firm and structured? Soft and flowable? Or is it somewhere in between?

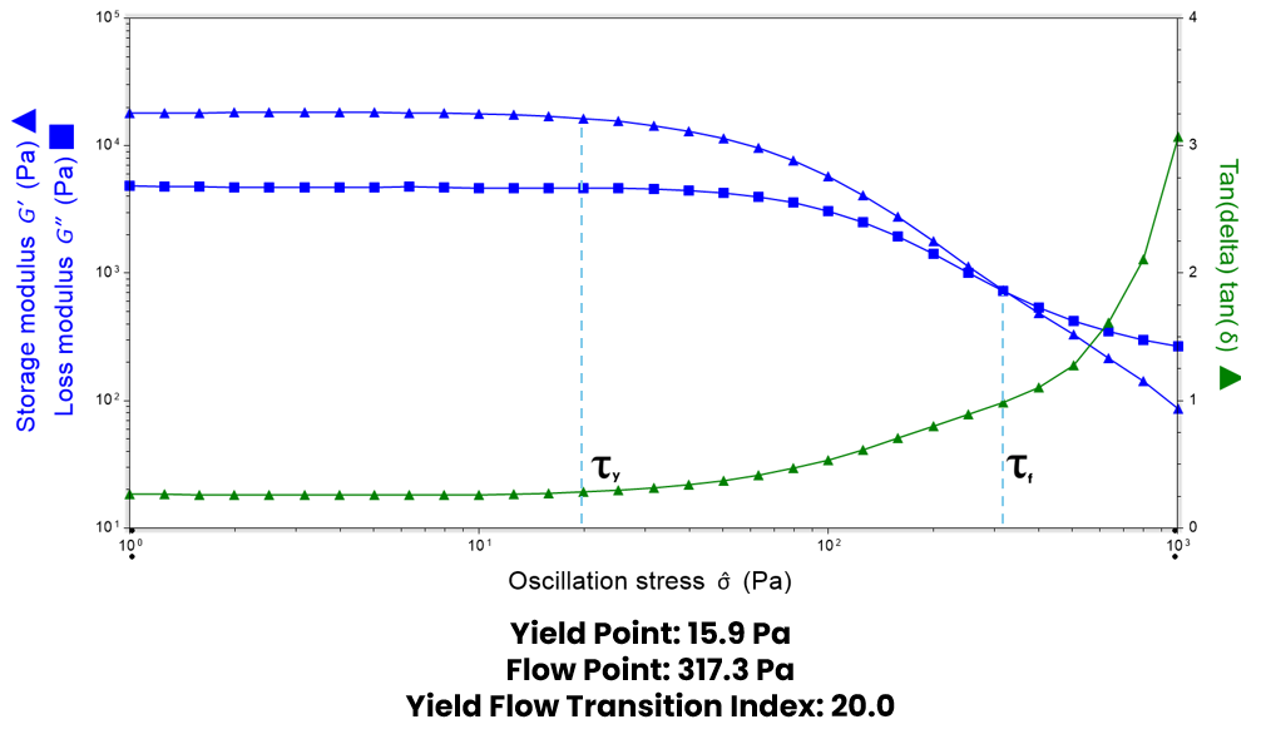

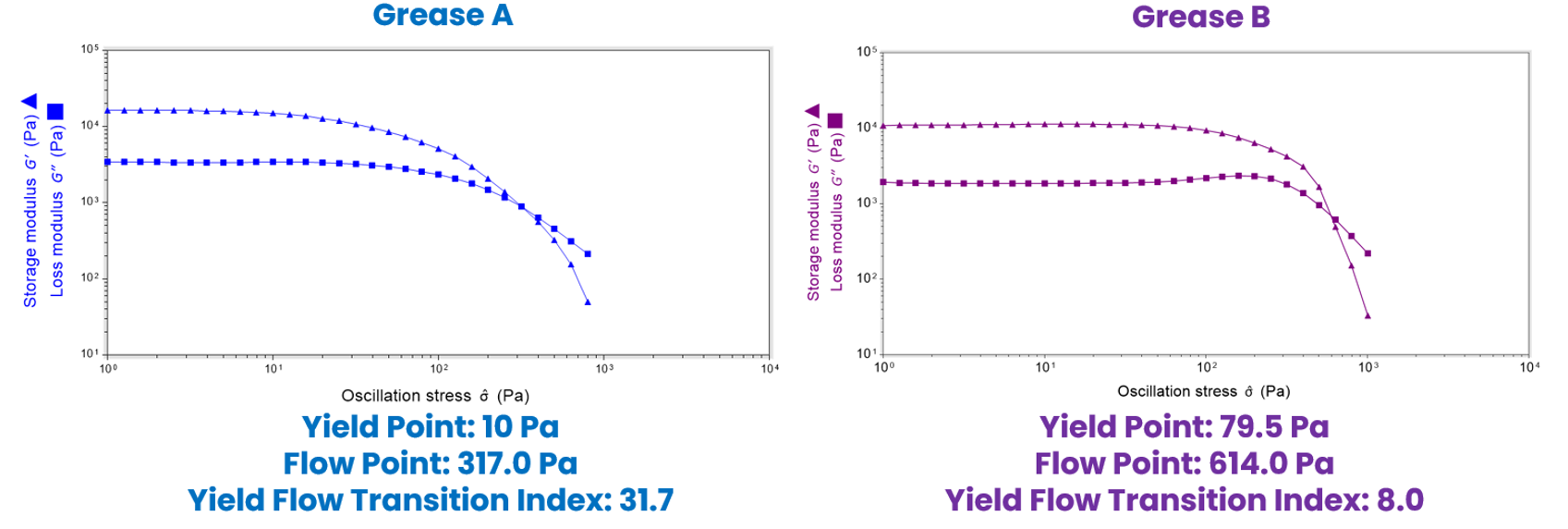

The graph in Figure 2 shows a typical output from an oscillation stress sweep of a grease, highlighting key points and derived parameters:

Yield Point () – the shear stress at which a grease begins the onset of permanent deformation.

Flow Point () – the shear stress at which a grease transitions from elastic-dominant behaviour to viscous-dominant behaviour.

Loss Factor (tan(δ)) – tangent of the phase angle, quantifies the ratio of viscous behaviour to elastic behaviour. It’s a quick indicator of how elastic or viscous a material behaves.

Yield Flow Transition Index – indicates how brittle the grease is upon breaking its internal structure. Values closer to 1 suggest more brittle grease behaviour.

ISO 13511 – Determination of The Consistency of a Grease

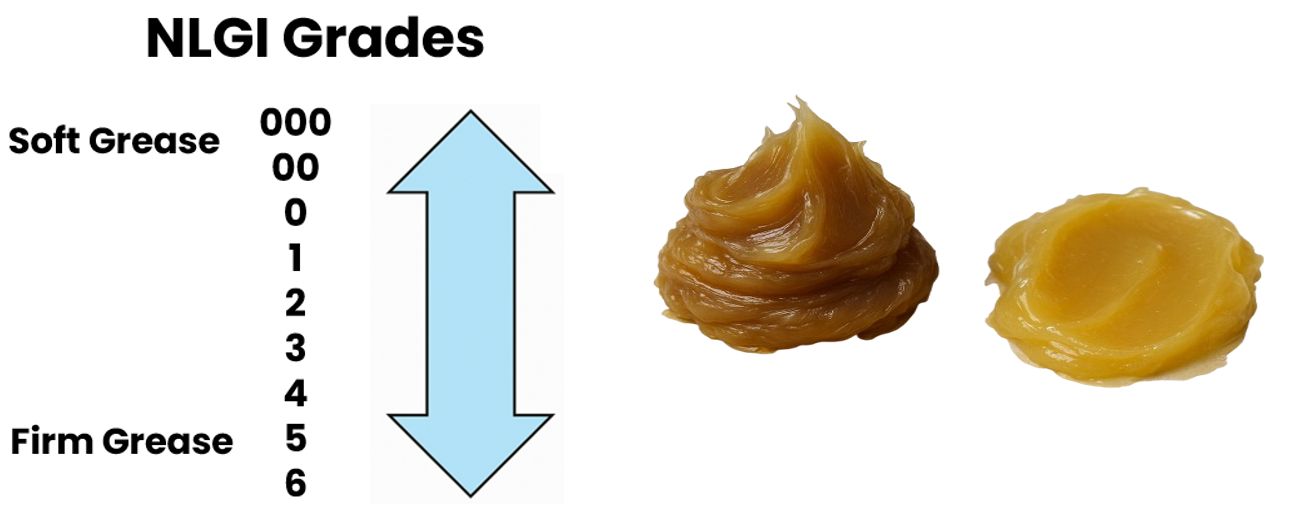

Consistency quantifies a grease’s relative hardness or softness. Primarily influenced by the type and concentration of thickener in a grease formulation, consistency directly impacts a grease’s ability to be pumped and to subsequently remain in place after application. Softer greases typically pump more readily, while firmer greases stay in place more easily after application. The optimal grease consistency depends on the specific application.

This ISO method requires oscillatory rheological techniques with a cone-plate geometry. The grease is subjected to controlled shear deformation at a defined temperature, and its viscous response (loss modulus) is measured.

The measured viscous response is analysed, and specific calculations convert the result into a worked penetration value, directly corresponding to a traditional NLGI consistency grade.

ISO 13227 – Determination of The Flow Point of a Grease

In grease rheology, the flow point and yield point provide essential insights into the performance of lubricating greases.

In this test method, a lubricating grease sample is tested using oscillatory rheological techniques with a parallel-plate geometry at precisely controlled temperatures. By applying oscillatory stress or strain, the rheometer measures the grease’s elastic and viscous responses, identifying the point at which the material structure yields and begins to flow. This test method is specific for greases with an NLGI grade of 0 to 2.

Figure 3 shows how the results from this ISO technique can be displayed graphically.

Rheological data obtained highlights the nuanced behaviour between these two greases, with the yield and flow point occurring at much lower stresses for grease A. This type of analysis is crucial for matching a grease’s performance to its intended application. For example, grease A may be better suited to low-load scenarios, while grease B may be suited for higher-load applications.

Among the flow point being characterised by this test, additional parameters are obtained from this analysis:

- Loss Factor

- Storage Modulus

- Loss Modulus

- Yield Point

- Yield Flow Transition Index

Ultimately, this shows the wealth of additional insights that are provided from this standardised test. You are not just simply getting a flow point value alone; you are also extracting variables that describe how the structure of the grease changes under increasing stress.

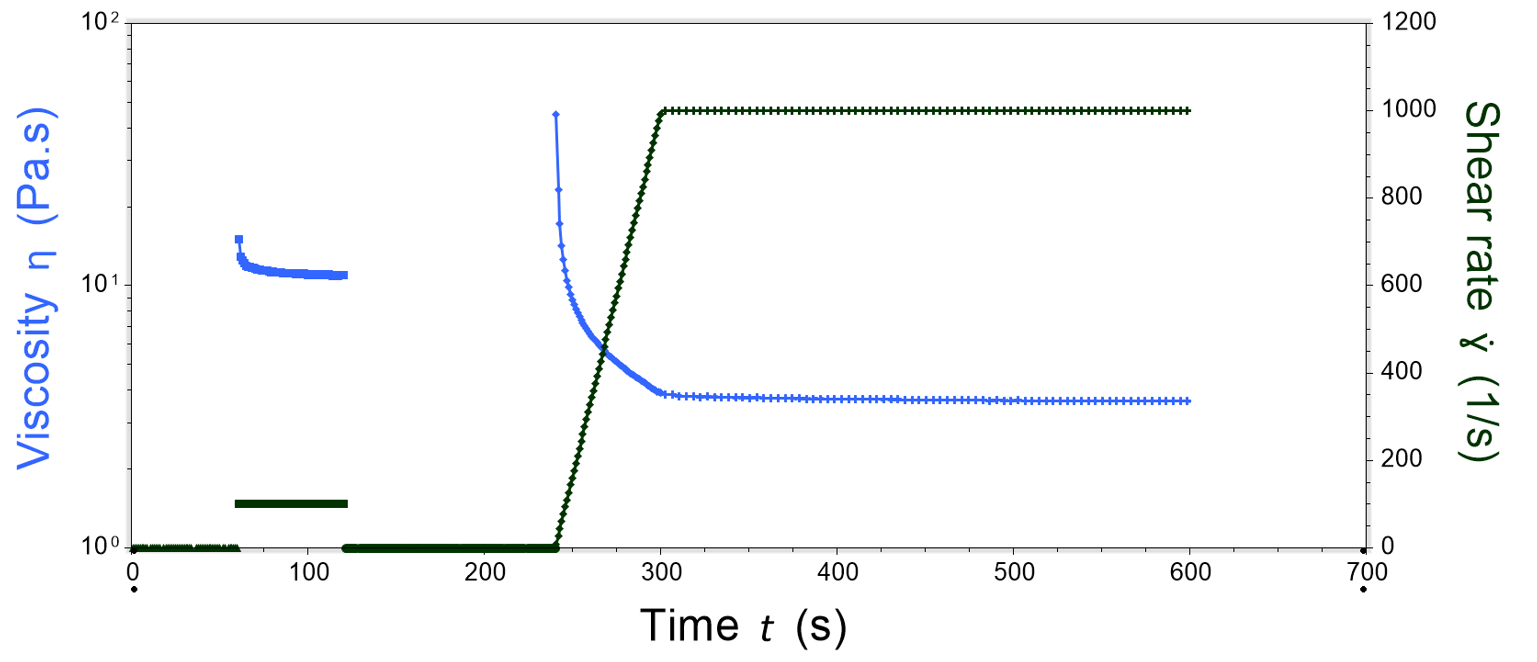

DIN 51810-1 – Determination of The Shear Viscosity of a Grease

This DIN standard outlines a method for characterising the shear viscosity of lubricating greases. This is a simple and rapid test utilising a cone-plate geometry. The test procedure is carefully staged to capture the material’s response to varying shear inputs.

Figure 4 shows a typical graphical output for this test, with the test sample being a dielectric grease. One of the most critical aspects of this graph is where the grease is held at a high and constant shear rate of 1000 s⁻¹ as it provides insights into the grease’s structural stability. A stable viscosity during this phase indicates the robustness of the structure under high-speed conditions, which is particularly important for many industrial and automotive applications.

In Progress ASTM WK85429

This ASTM is a new test method that is currently still in progress. It covers the determination of the storage modulus and flow point stress for greases with an NLGI grade from 1 to 3.

Once this ASTM is complete, we will be able to provide rapid access to these insights.

Summary

In addition to the rapid access to these standardised rheological tests, we have been helping industry leaders innovate with insights that extend beyond standard tests. Our advanced capabilities support innovation in formulation development.

Related Articles;

Rheo-Impedance Spectroscopy for Microstructural Insights of Thermally Aged Greases

Rheo-Impedance Spectroscopy for Dielectric Characterisation

Identifying Suitable Grease Alternatives with Rheology

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.