For products such as coatings, foods, pharmaceuticals, cosmetics and building materials, a knowledge of rheological properties offers instant insight into otherwise hidden attributes that contribute to their processing, handling, stability, texture and performance.

Our customers use our rheology testing lab services to:

-

Predict suspension or emulsion stability

-

Reformulate with alternative ingredients

-

Benchmark against their competitors and reverse engineer to a target or reference formulation

-

Understand the impact of processing and filling on the final product

-

Predict sensory and texture properties to reduce dependence on sensory panels

Rheology measurement methods

Start with a Rheology Snapshot…

For a super-quick insight into overall rheology properties, a “rheology snapshot” is a great starting point, delivering simple yet powerful insights for your product.

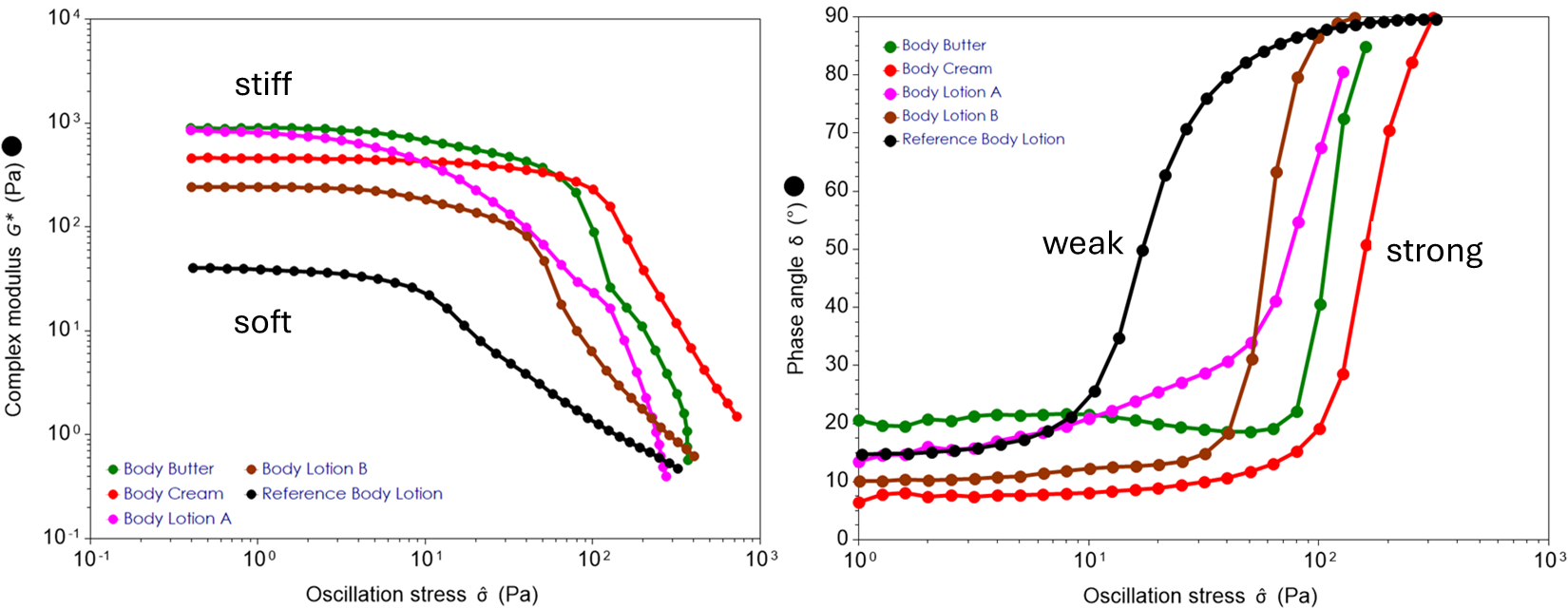

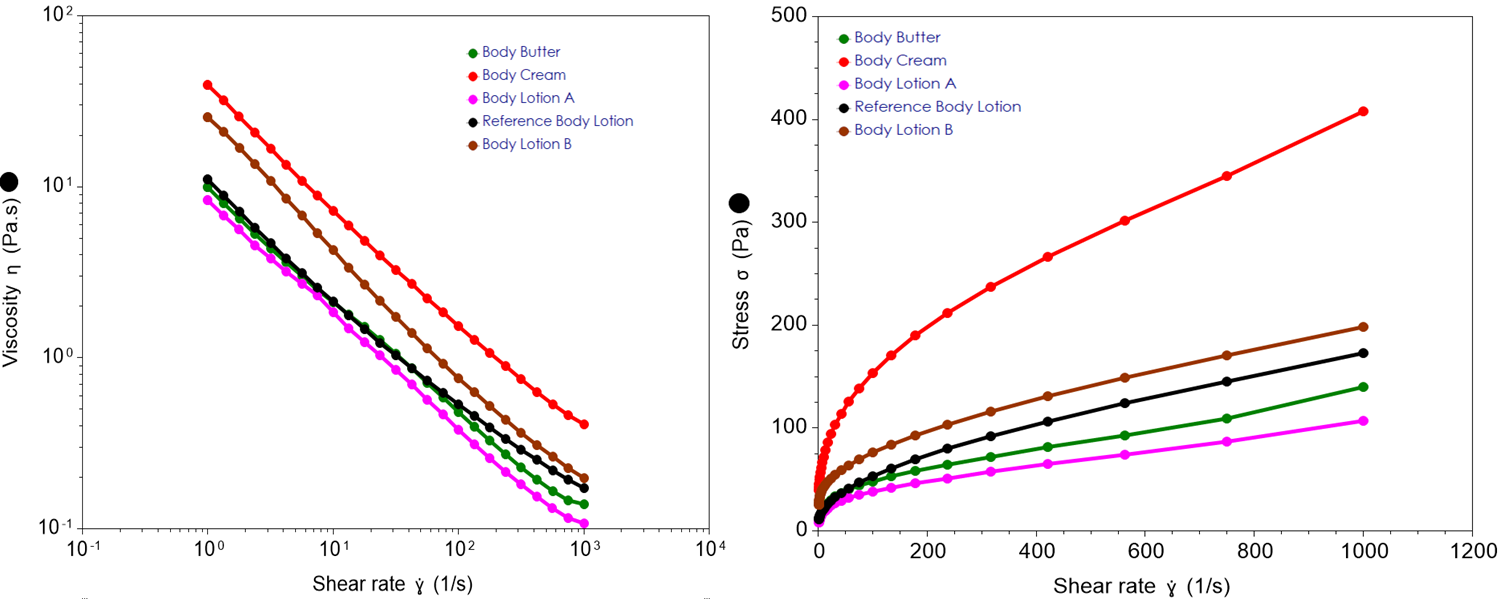

Many materials, such as suspensions, emulsions and gels, can be thought of as structured liquids. They exhibit both soft-solid structure but can be easily made to flow like a liquid. The rheology snapshot captures the structure and flow properties of a sample:

Measuring Structure

Oscillatory stress or strain sweeps gently probe a sample’s microstructure. Structure results are delivered in the form of storage modulus (G’), loss modulus (G”) yield stress (structure strength) and phase angle.

Measuring Flow

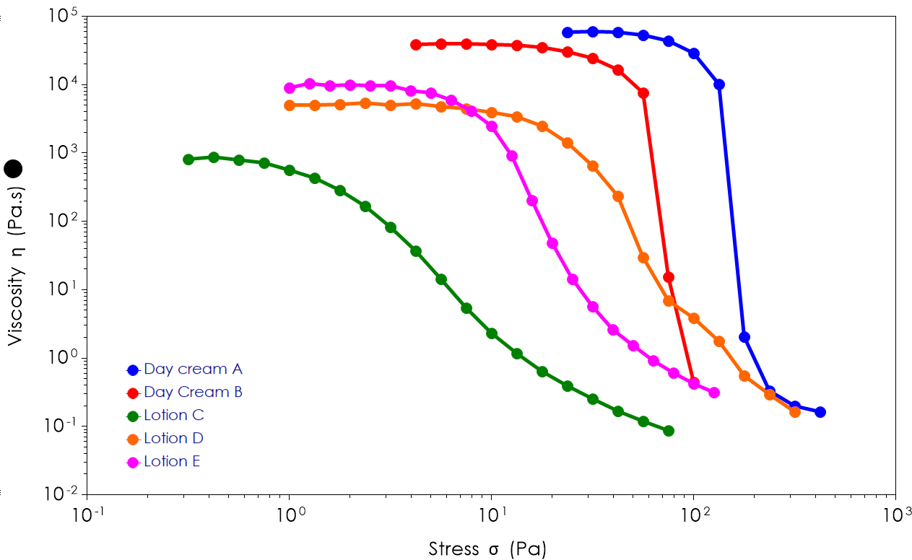

Viscosity measurements are performed across a range of shear rates to capture any non-Newtonian flow behaviour. Viscosity results are typically reported in units of Pascal seconds (Pa.s) or centiPoise (cP)

The results are easy to understand and interpret.

Then choose a deeper rheological analysis…

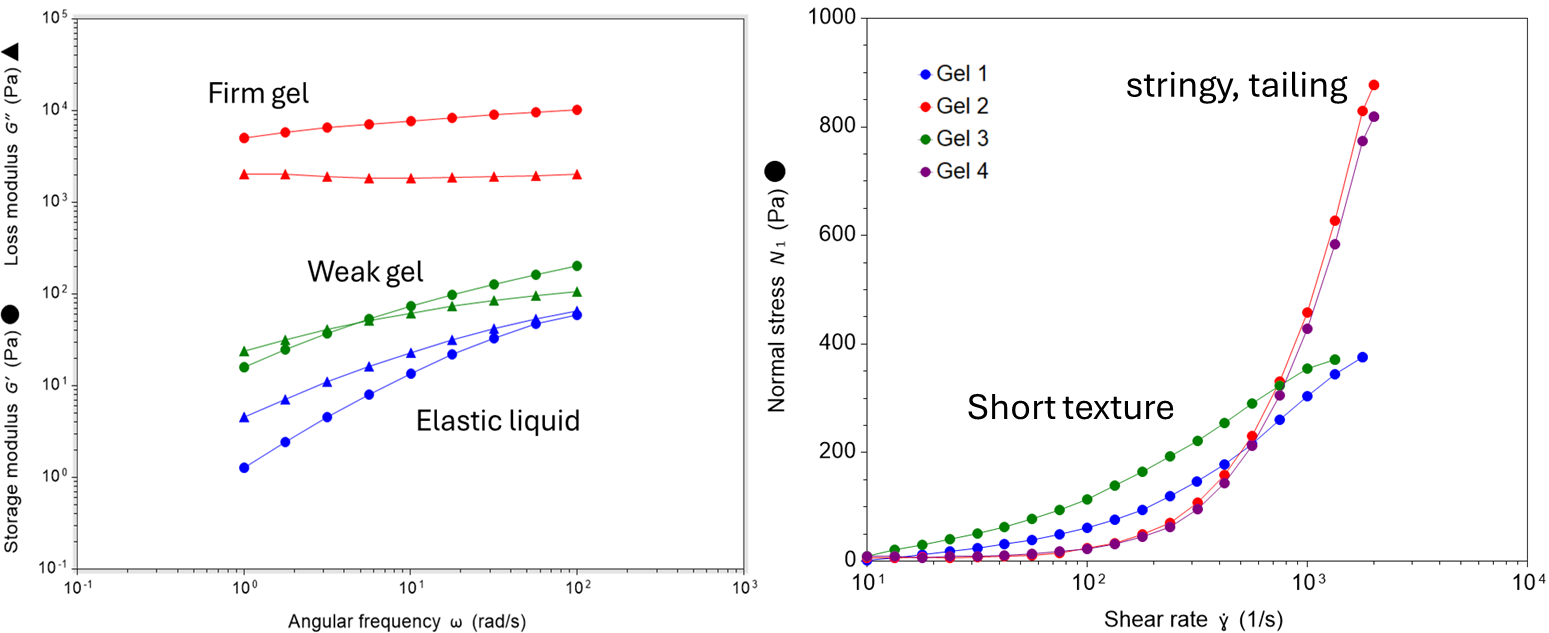

Viscoelasticity

Viscoelasticity analyses can predict behaviours that lead to handling and appearance properties, lubricity, stringing and tailing, film-formation and potential pumping issues. Small angle oscillatory shearing, also known as dynamic rheological profiling delivers storage (or elastic) modulus (G’) and loss (or viscous) modulus G”, phase angle and/or tan delta measurements. Normal stress measured under shearing can predict the extensional rheologies that lead to long, stretchy textures and processing and filling problems.

Zero-shear viscosity

This special case of viscosity predicts the mobility of suspended particles or emulsified droplets when a material is in an almost at-rest condition. The measurement takes place at incredibly low rotational rates (as low as one revolution in three months!) but only takes half an hour or so to perform.

Zero-shear viscosity measurements are reported in Pascal seconds (Pa.s) or Poise (P)

Thixotropy analyses

Thixotropic materials are those that show a time-dependent viscosity change following either the application or the cessation of shearing. Thixotropic liquids typically include suspensions and emulsions, where the breakdown and subsequent recovery of colloidal structures are not instantaneous but take time to progress to a new equilibrium state. The most commonly required output of a thixotropy measurement is a quantification of the “thixotropic recovery rate”, the time taken for viscosity to rebuild to an acceptable level after shear is removed. This determines, for example, the ability for a coating or ink to maintain position following application or the ability for an adhesive to “grab” and maintain contact whilst a cure proceeds. “Thixotropic breakdown rate” is also of interest in situations such as pump or process start-up, where the assembled structure is to be disrupted to initiate flow, and the application of products to the skin, where a protracted thixotropic breakdown can result in poor spreadability.

Temperature profiling and cycling

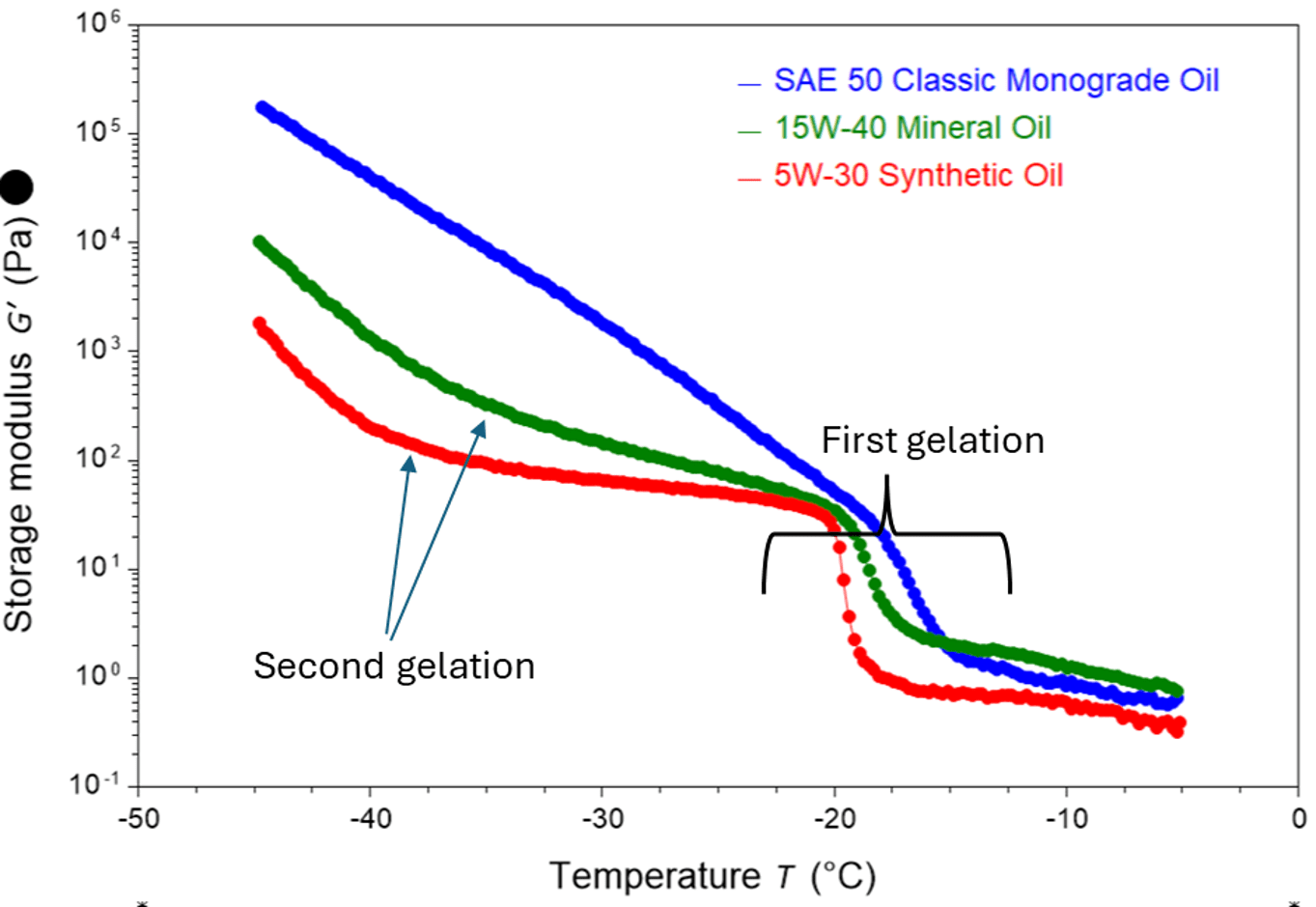

For materials that undergo phase changes such as melts and crystallisations, oscillatory temperature sweeps can provide excellent themorheological fingerprints that are excellent for benchmarking and second-sourcing waxes and hydrocarbon-based products. For starch slurries that gelatinize or thermoset adhesives and resins that undergo gelation and curing oscillatory temperature sweeps or isothermal time sweeps enable the easy identification of key points such as viscosity minima, cure times and gel points. Furthermore, the influence of storage temperature cycles can be investigated with cyclic oscillatory “swing” tests.

Creep and recovery

Creep testing delivers strain or compliance measurements as a function of time under very low stresses. Creep testing is often employed as a means for obtaining zero-shear viscosity but can also provide rapid indications of the propensity for materials to sag or slump following deposition and application.