Fabric conditioners offer a simple and effective way to keep clothes soft and smelling fresh. In this study, we present our newest technique, rheo-impedance spectroscopy, to investigate cationic surfactant relaxation processes in two leading commercial products – Lenor Outdoorable and Comfort Fresh Blue Skies.

Alongside this specialised technique, we provide a comprehensive overview of the key rheological properties that are essential for characterisation. This ensures you understand how your product performs under different conditions, supporting formulation development

How do Fabric Conditioners Work?

During a wash cycle, clothes are typically washed with detergents containing anionic surfactants. These anionic surfactants leave fabric fibres with a negative charge. When fabric conditioners are added during the rinse cycle, the positively charged cationic surfactants present within the formulation are attracted to the negatively charged fibres.

As such, the cationic surfactants adhere to the surface of the fabric fibres, creating a thin, lubricating film on the surface of the fibres. This lubricating film reduces friction, making fabric feel softer. The film can also help to neutralise any static charge that may build up, particularly during a drying cycle.

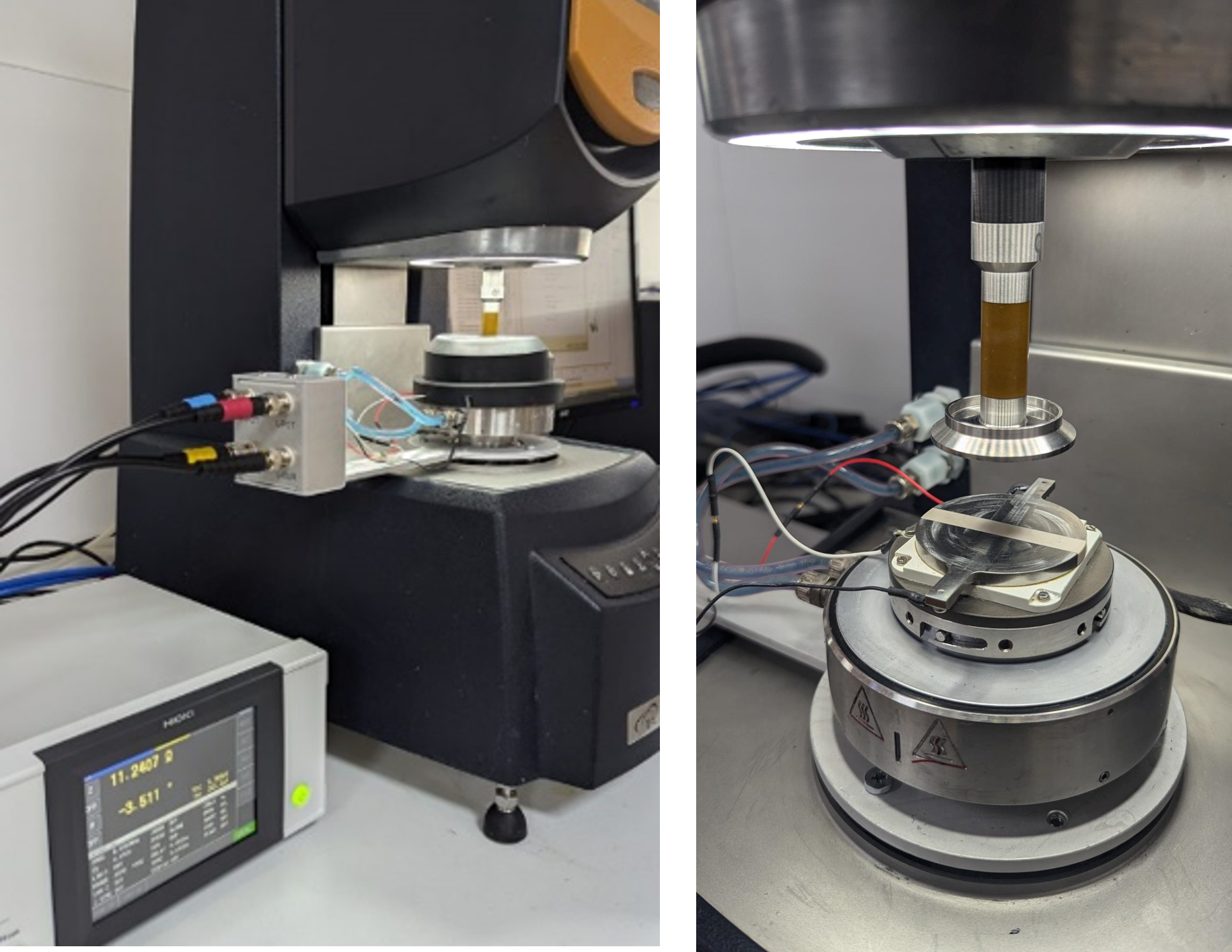

Rheo-Impedance Spectroscopy for Fabric Conditioners

Both fabric conditioners stated they contained 5-15% cationic surfactants; however, they did not specify the exact concentration or type used. Therefore, we employed rheo-impedance spectroscopy to investigate the relaxation mechanisms of surfactants present.

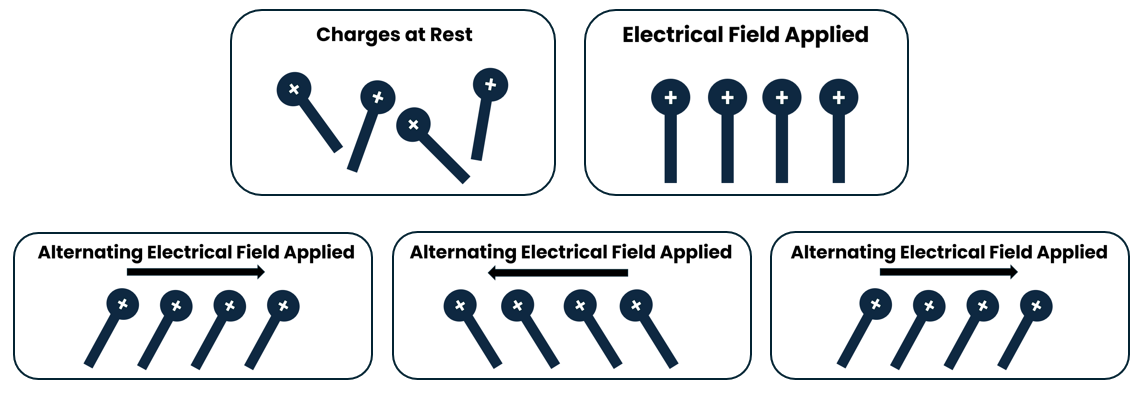

This allows us to identify differences in permittivity behaviour between samples, potentially indicative of variations in cationic surfactants. During our analysis, we apply an alternating electrical field to the sample to cause polarisation, the shifting of internal charges.

Permittivity can be obtained from this behaviour; it describes how much a material becomes polarised when an alternating electrical field is applied.

The energy that is stored through polarisation is represented by storage permittivity, the in-phase response. Loss permittivity is the out-of-phase response, representing how dissipative or lossy a material is, and is our focus for this study.

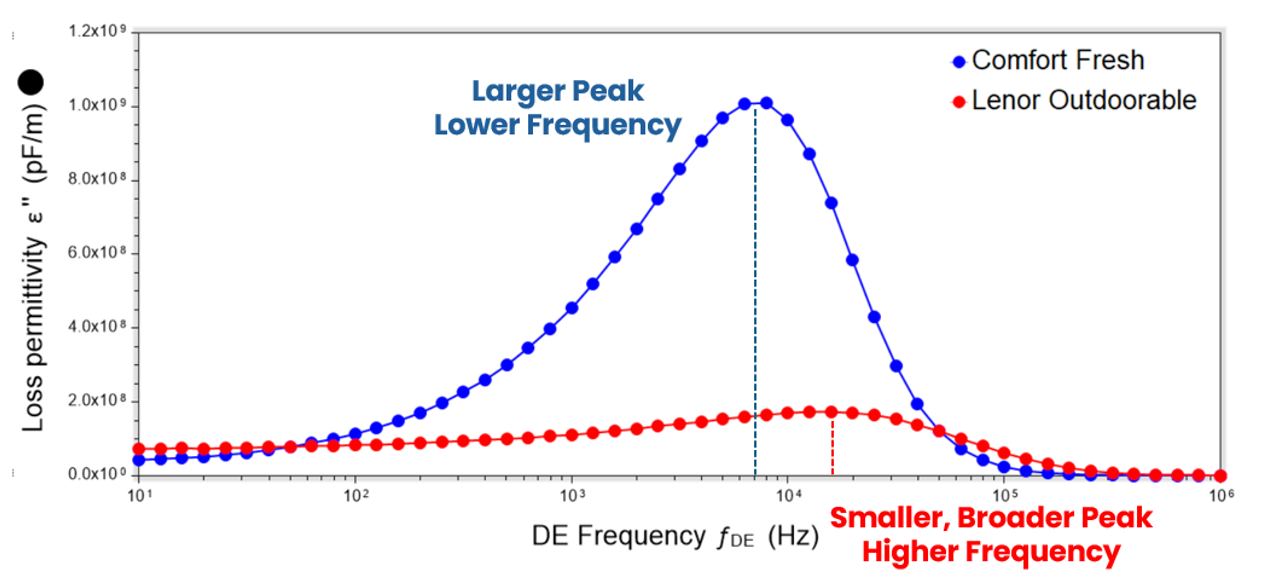

The frequency at which a peak in loss permittivity occurs can provide insights into the molecular size of surfactants present. Specifically, a peak at lower frequencies signifies larger molecules that require more time to relax, corresponding to slower dipolar relaxation times.

The magnitude of the loss peak provides insights into the inherent lossy behaviour of the surfactants, and it may also reflect the concentration of surfactants present.

Comfort Fresh exhibits a prominent loss permittivity peak at approximately 8 kHz, with an associated dipolar relaxation time of 20 microseconds. The peak’s magnitude likely indicates a higher concentration of surfactant molecules present.

In contrast, Lenor Outdoorable exhibits a smaller peak at approximately 16kHz, with a faster relaxation time of 10 microseconds. This indicates smaller-sized cationic surfactants compared to Comfort Fresh, and its associated smaller peak likely corresponds to a lower concentration of surfactants present.

Overall, the results demonstrate that both samples exhibit a unique impedance spectroscopy fingerprint reflective of their composition. This characteristic fingerprint can be used as a benchmarking tool to evaluate formulation consistency and to assess the impact of ingredient modifications. By comparing permittivity profiles, one can aim to match or improve upon a target fingerprint, whether your own or that of a competitor. Additionally, this technique can be used to compare fresh and aged samples, ensuring that aged formulations retain the desired surfactant properties.

Rheological Characterisation for Fabric Conditioners

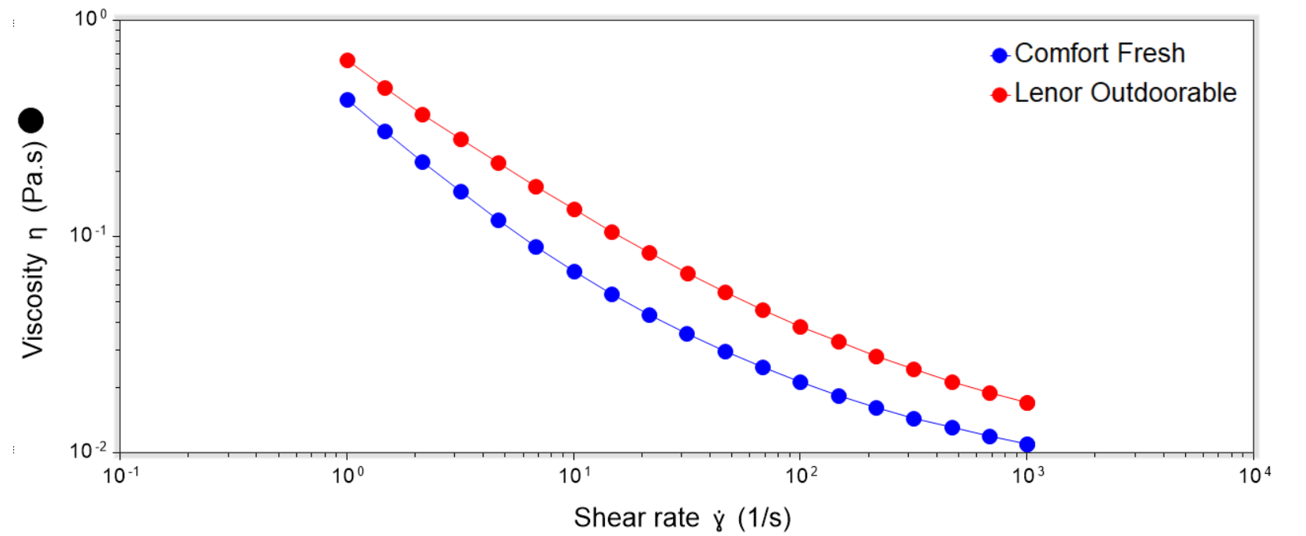

Viscosity Measurements for Flowability

The use of a rheometer allows characterisation of viscosity over a range of shear rates, offering more comprehensive insights than single-point measurements obtained from basic viscometers.

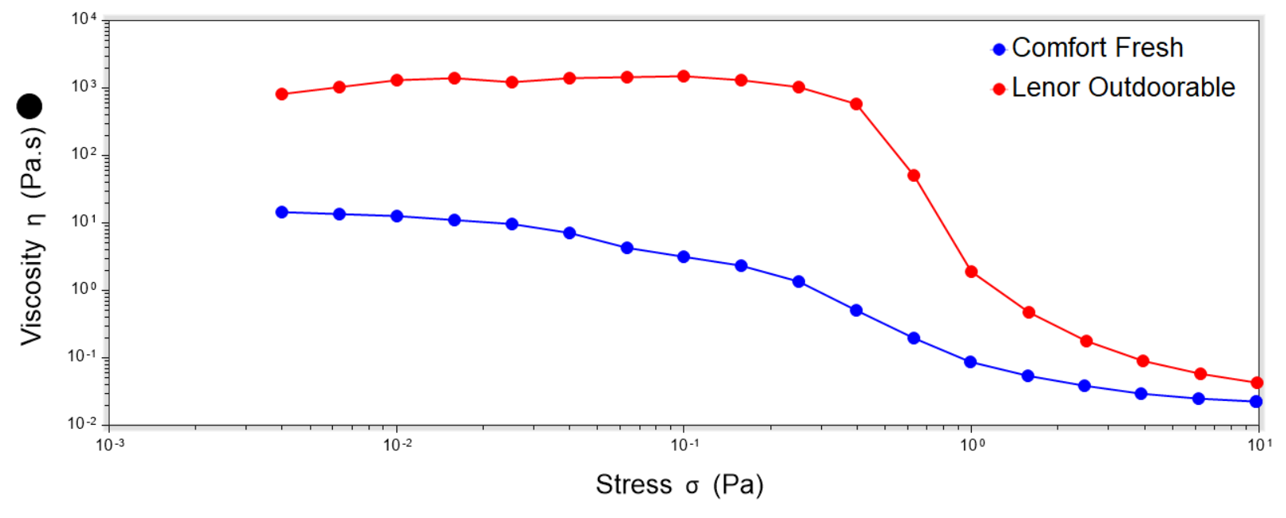

Both Lenor Outdoorable and Comfort Fresh exhibit non-Newtonian shear-thinning behaviour, characterised by a decrease in viscosity as shear rate is increased. A decrease in viscosity of approximately 2 decades is observed across the shear rate range tested for both products. This allows the product to maintain sufficiently high viscosity at rest, whilst also flowing easily when poured.

One may initially expect Comfort to have a higher viscosity based on its dielectric spectrum, suggesting larger surfactants of a higher concentration. However, the rheological data shows otherwise. A possible explanation is that Lenor may contain a higher level of salts, commonly used as viscosity modifiers in fabric conditioners. This added salt can also slightly shorten the dipolar relaxation time, further explaining its shift in permittivity peak compared to Comfort.

At Rest Viscosity Measurements – Zero-Shear Viscosity

Using our advanced research rheometers, we can also capture the zero-shear viscosity. The zero-shear viscosity reflects that of a product when it is effectively at rest, with a higher value acting as a contributor to increased stability. It can be difficult to characterise without advanced techniques; however, our instruments offer extraordinary sensitivity, capable of detecting rotational speeds as slow as 1 revolution every 3 months. Despite this, we obtain rapid results in as little as 30 minutes.

The plateau observed at low stresses reflects the zero-shear viscosity. A high zero shear viscosity is a proxy for shelf stability. At rest, it helps immobilise droplets in emulsions such as fabric conditioners. Figure 6 highlights that Lenor’s zero shear viscosity is approximately two decades higher than that of Comfort.

In addition to this, both products’ zero-shear viscosities sit well above the lowest-shear data shown in Figure 5. A difference of over a decade is observed for Comfort, and a huge difference of over 3 decades is observed for Lenor. These differences highlight the crucial insights that can be missed if you are not utilising advanced rheological methods to characterise your formulations.

Probing Delicate Structure Through Oscillatory Stress Testing

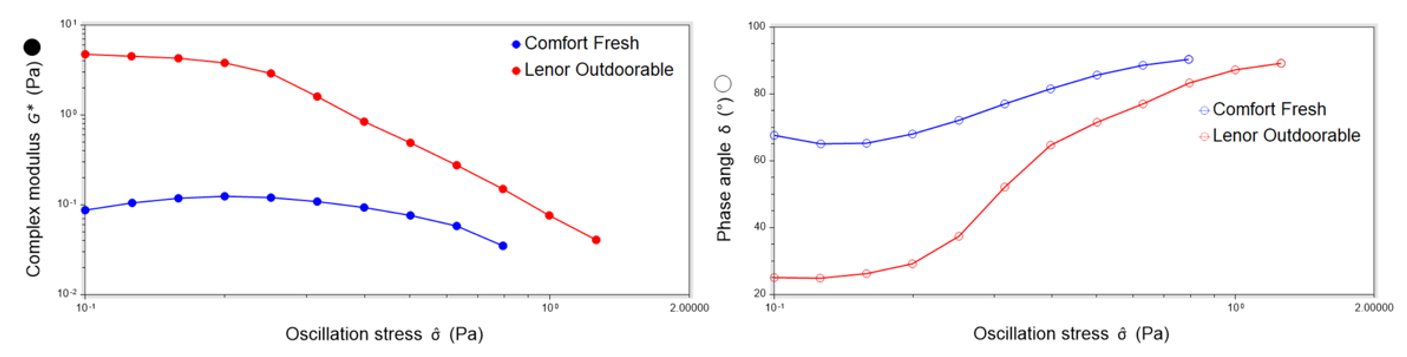

Fabric conditioners commonly exhibit viscoelastic behaviour with small yield stresses. This low yield stress is beneficial as it prevents the sample from flowing under its own weight in the bottle, aiding long-term stability.

We can probe the delicate structure present within a sample through oscillatory techniques. The complex modulus is obtained through these techniques, which describes the overall resistance to deformation, essentially, the rigidity of the sample. Phase angle data is also obtained, which describes the relative contributions of elastic and viscous behaviour. A phase angle of 90° indicates viscous dominance, whereas a phase angle of 0° indicates elastic dominance.

Figure 7 highlights the distinct differences in the viscoelastic behaviours of both samples. Lenor displays a small yield stress of 0.31 Pa. In contrast, Comfort exhibits a phase angle exceeding 45° even at the lowest stresses. This is indicative of a very delicate structure, with yield stress becoming an irrelevant metric in this situation.

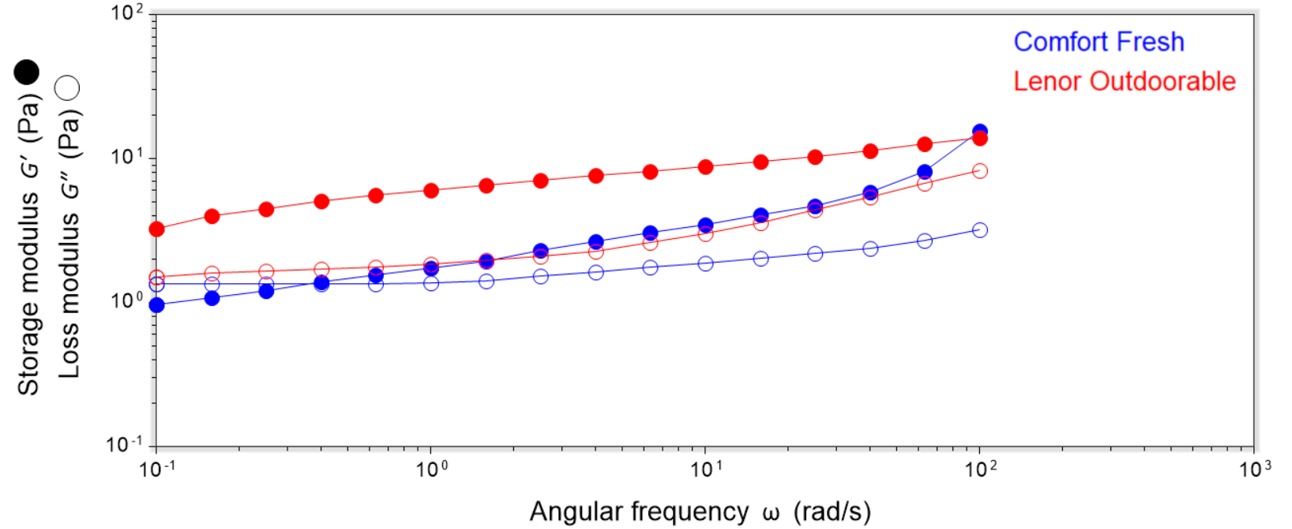

Nuanced Insights Through Oscillatory Frequency Measurements

An oscillation frequency sweep can be conducted to reflect timescale-dependent viscoelastic deformation. In this test, the frequency at which the deformation is applied is increased while maintaining a constant oscillatory stress. The complex modulus is split out into its in-phase and out-of-phase responses:

- Storage Modulus – reflects the elastic (solid-like) response

- Loss Modulus – reflects the viscous (liquid-like) response

Comfort exhibits a loss modulus higher than the storage modulus at low frequencies. This means that at longer timescales of deformation, the product behaves more like a liquid. As frequency is increased, a crossover frequency is observed, where the storage modulus is now higher than the loss modulus, indicating that the sample behaves more like a solid at shorter timescales of deformation. This is an example of classic timescale-dependent viscoelastic behaviour. Lenor consistently exhibits elastic dominant behaviour across the frequency range tested, with its modulus values indicative of a delicate but well-defined structure.

Summary

Our initial findings using rheo-impedance spectroscopy highlight the exciting insights that can be unravelled into surfactant relaxation processes in fabric conditioners. Equally, our comprehensive rheological characterisation services demonstrate why advanced techniques are essential. Viscosity measurements revealed non-Newtonian, shear-thinning behaviour, along with a distinct zero-shear viscosity plateau.

These behaviours are unable to be fully characterised with basic viscometers and provide essential insights for predicting long-term stability and ensuring your fabric conditioner is delivering the premium pouring experience that consumers expect. If you would like to explore how our expertise can support your product development, do not hesitate to contact us.