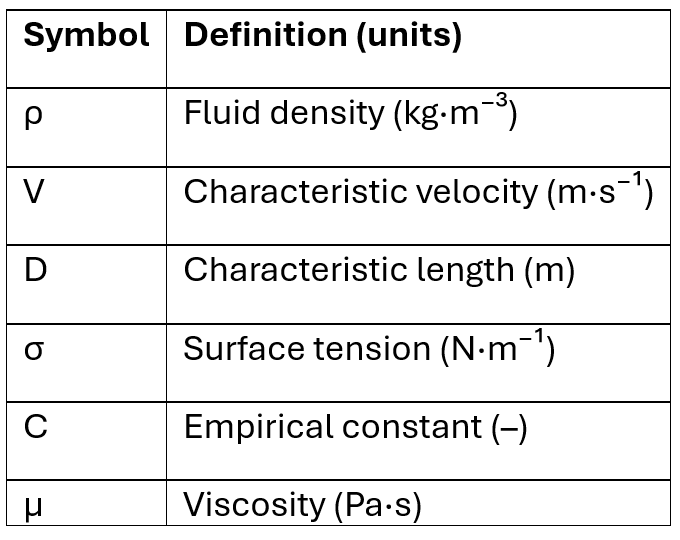

Consumers expect household surface sprays to spray effortlessly with large surface coverage. However, optimising formulations for enhanced atomisation remains a persistent challenge. Among the suite of physical properties relevant to atomisation that we can measure, this study focuses on viscosity and surface tension.

Spraying and Atomisation: A High-Shear Process

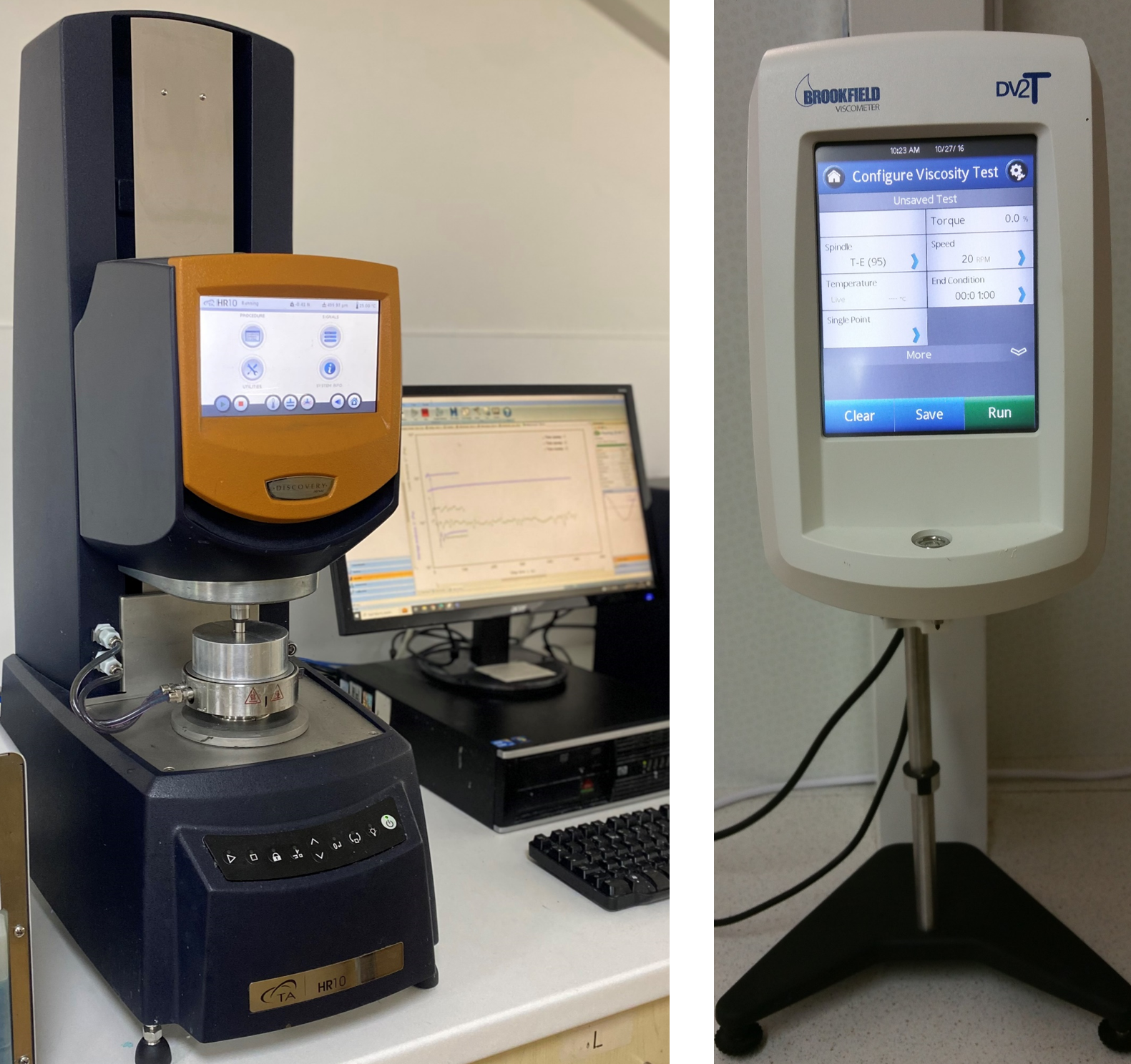

Basic viscometers are often used to characterise these products; however, products like a Brookfield DV2RV have a limited maximum spring torque of 0.7187 mN·m. Long before the target deformation rate is reached, the instrument’s torque ceiling is hit, and as such, these viscometers cannot attain the higher shear rates relevant to this process.

Plate-plate measurements conducted on a rheometer overcome this issue. With a maximum torque 200 mN·m, around 278x larger, on a TA Instruments DH10 rheometer, they can achieve significantly higher deformation rates. By operating with very small gaps and at higher rotational speeds, rheometers can precisely quantify high-shear behaviour. The small sample volume required in plate-plate setups inherently facilitates excellent temperature control, ensuring accurate and highly reproducible data.

Under The Surface of Spray Atomisation

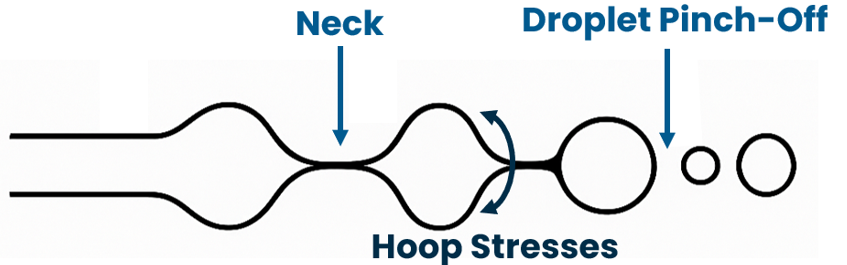

As a liquid exits a spray nozzle, atomisation is promoted through Rayleigh instabilities. Rayleigh instabilities are a natural result of surface tension acting to minimise surface area, creating hoop stresses that squeeze the jet inward. As Rayleigh instabilities grow, narrow necks are formed. Eventually, the necks become so thin that the liquid pinches off, separating into droplets. High viscosity results in instabilities growing more slowly, suppressing the thinning of the necks, and inhibiting droplet pinch-off. This leads to poor atomisation.

It is important to note that while surface tension drives hoop stresses that squeeze the jet inward, the jet resists this compression through its extensional viscosity. Many liquids are Newtonian, as characterised in this study, in which the extensional viscosity is simply three times that of the shear viscosity. However, if high molecular weight thickeners are incorporated to prevent sedimentation or add other functional benefits, then extensional viscosity can increase dramatically despite apparent shear thinning behaviour. Such changes can have knock-on detrimental effects on atomisation. This extensional behaviour cannot be captured using a viscometer, underscoring the importance of utilising advanced rheological techniques.

Rheological and Interfacial Analysis of Household Surface Sprays

We conducted both viscosity and surface tension measurements of some common household surface sprays to identify any differences in behaviour between formulations.

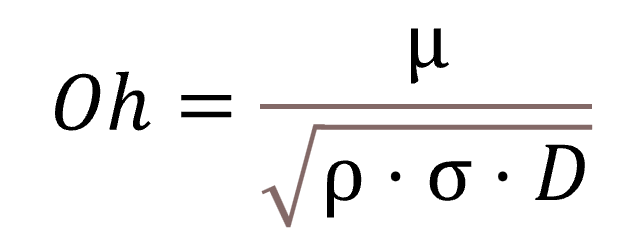

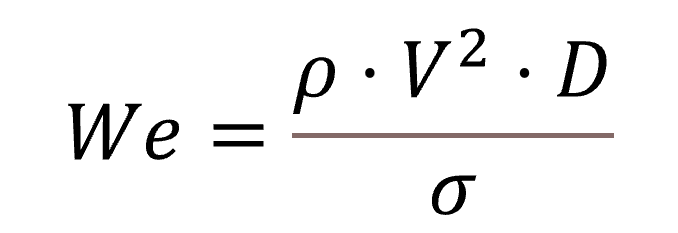

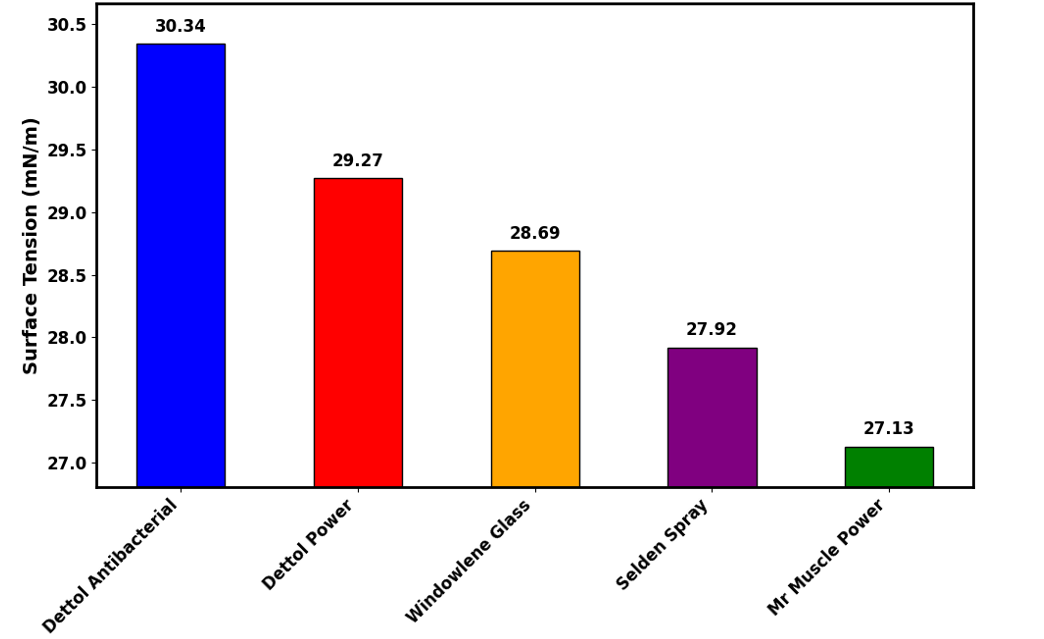

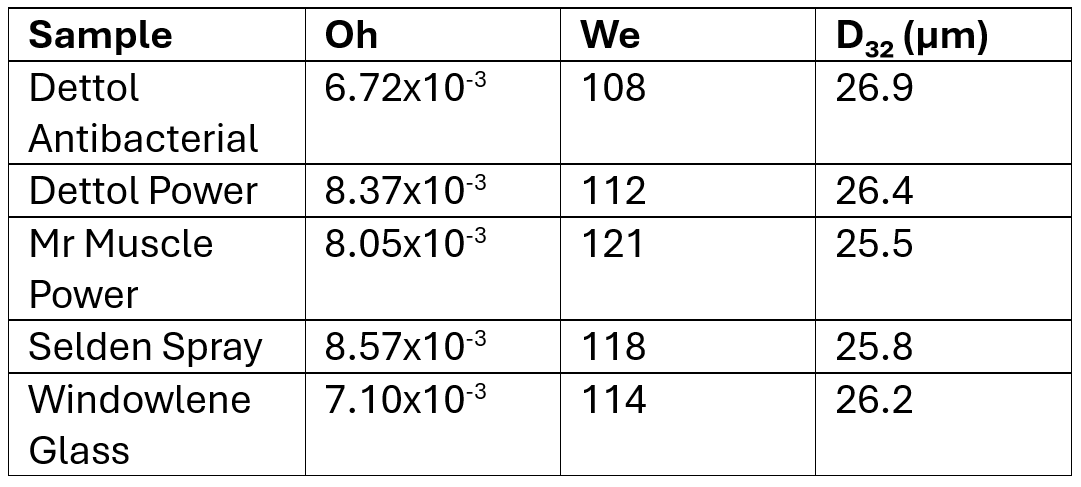

To relate the characterised surface tension and viscosity values to atomisation, we carried out further calculations to compare and benchmark between samples using the following parameters:

Ohnesorge number – describes the ratio of viscous forces to the combined effect of inertial and surface tension forces When Oh < 0.1, inertial and surface tension forces dominate, and viscous effects are minimal. Generally, a lower Ohnesorge number is desirable for promoting effective droplet breakup for surface sprays.

When Oh < 0.1, inertial and surface tension forces dominate, and viscous effects are minimal. Generally, a lower Ohnesorge number is desirable for promoting effective droplet breakup for surface sprays.

Weber number describes the balance between inertial forces and surface tension forces in a fluid.  A higher Weber number indicates that inertial forces are dominant, indicating a greater tendency for liquid pinch-off.

A higher Weber number indicates that inertial forces are dominant, indicating a greater tendency for liquid pinch-off.

Sauter Mean Diameter (D32) – a representative droplet size that reflects both volume and surface area. It allows a comparison of droplet size across formulations.

![]()

The Sauter Mean Diameter can be predicted using the empirical correlation above, based on the previously calculated Weber number.

The empirical constant (C) accounts for effects not captured by the Weber number. We assume C as 0.725 based on Hinze’s turbulent-breakup analysis [1]. This value provides a common baseline for comparing formulations.

For these calculations, a characteristic length of 0.4mm was selected, which is taken as the diameter of the nozzle. A volumetric flow rate of 0.36 m3s-1 was assumed based on similar literature reported values, resulting in a fluid velocity of 1.83 ms-1 [2]

Results

Viscosity

The results revealed that all samples exhibited Newtonian behaviour, with viscosity remaining constant across all shear rates. The small increases observed at higher shear rates occur due to turbulence and are a measurement artefact. While this sample set did not show non-Newtonian behaviour, it is important to note that other samples may exhibit shear-thinning properties. Having the ability to characterise this behaviour can be crucial for formulation optimisation and development. Among the tested products, differences in viscosity were observed.

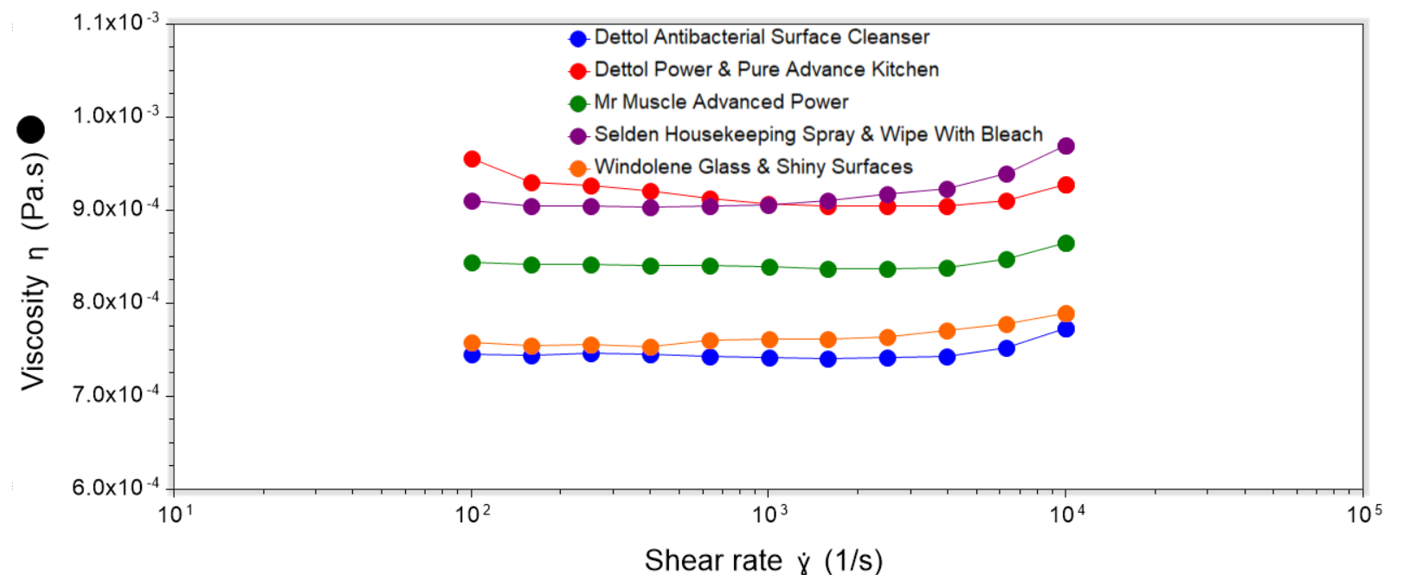

Surface Tension

We performed pendant drop analysis to characterise the surface tension of the formulations.

The data shows that Dettol Antibacterial has the highest surface tension at 30.34 mN/m, while Mr Muscle Power has the lowest at 27.13 mN/m. Although these differences are small, they are potentially significant. To explore this further, the analysis was extended through further calculations.

Further Calculations

Analysis of the spray formulations utilising these calculated variables revealed nuanced insights into their atomisation behaviour, particularly through the Weber number and predicted Sauter mean diameter. The calculated Ohnesorge number for all samples is below 0.1. This indicates that viscous effects are weak and that inertial and surface tension forces dominate. In other words, their viscosity is not high enough to inhibit droplet pinch-off.

Mr Muscle Power exhibits the highest Weber number, indicating a greater tendency for the liquid to break up into smaller droplets when compared to the other samples. This results in the smallest Sauter mean diameter, suggesting enhanced spray quality through finer atomisation and potentially improved surface coverage. Specifically, Mr Muscle Power achieved a 25.5µm mean droplet size, 1% finer than its next competitor. Although differences are marginal, this improved atomisation can lead to an enhanced consumer experience.

Overall, while no single parameter captures the full complexity of spray behaviour, calculation of these additional parameters provides further insights into droplet behaviour than just viscosity and surface tension measurements alone. This allows for easier comparisons of spray performance across different formulations.

Summary

Basic viscometry alone is often insufficient for fully understanding the performance of household surface sprays. By incorporating advanced rheological characterisation, which covers a broad range of shear rates, along with surface tension measurements, we can better characterise surface spray formulations.

Whether you are optimising for enhanced atomisation or benchmarking between products, our comprehensive testing capabilities can aid in formulation development. If you want to hit that perfect mist in a single trigger pull, do not hesitate to contact us to discuss how we can help with characterising your surface spray formulations.

References

[1] – Hinze JO. Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes. AIChE J. 1955;1(3):289-295.

[2] – Prud’homme de Lodder LCH, Bremmer HJ, Pelgrom SMGJ, Park MVDZ, van Engelen JGM; National Institute for Public Health and the Environment (RIVM). Disinfectant Products Fact Sheet. RIVM report 320005003/2006. Bilthoven: RIVM; 2006.