Newcomers to powder flow measurement often struggle with all the shear cell metrics such as angle of internal friction and cohesion from a yield locus and then using Mohr circles to derive unconfined failure strength, major principle stress and subsequent flow functions. In the short video we’ve tried to make it as intuitive as possible.

If you have any questions don’t hesitate to get in touch.

The transcript follows…

Powder Shear Cell – Characterising Powder Flow Behaviour

The flow-ability of a powder is subject to the aggregate effects of multiple particle properties, interactions and environmental conditions.

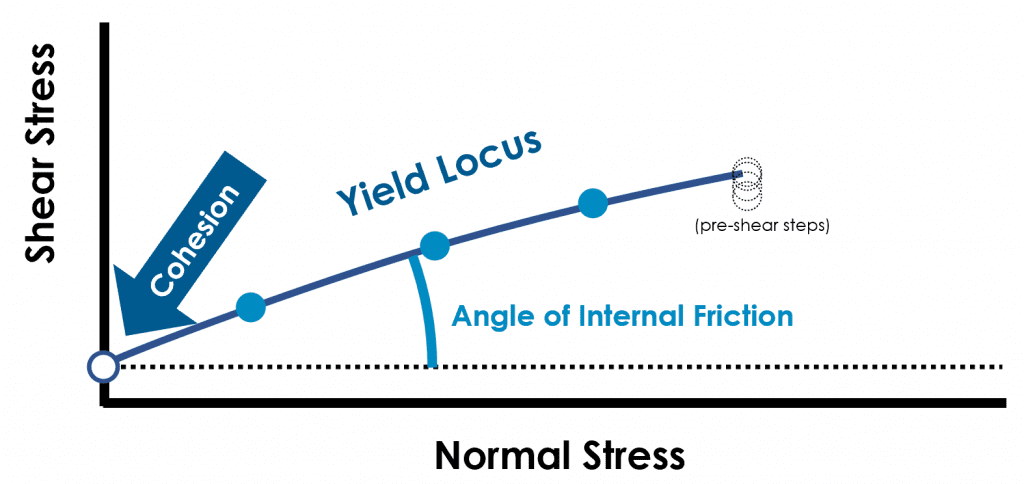

Shear cell measurements entail applying a range of load stresses to a powder bed and measuring the shear stress at the point of incipient flow for each.

From the “yield locus” obtained it is possible to quantify key flowability metrics including cohesion and the angle of internal friction. Cohesion can be thought of as the intrinsic strength of a powder mass resulting from particle interactions. The angle of internal friction is a measure of how the powder mass gains strength with increasing load stress.

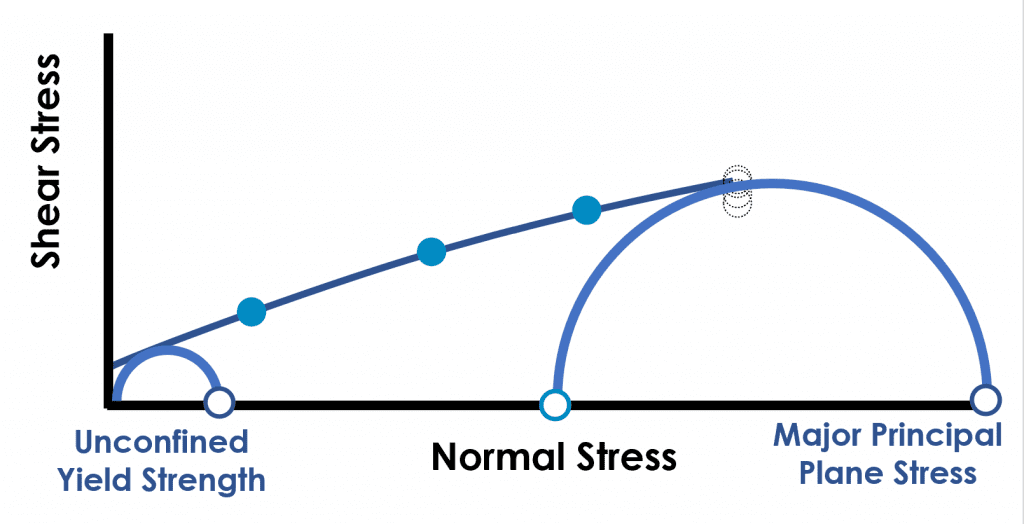

With the construction of Mohr’s circles onto the yield locus the unconfined yield strength at an associated major principle consolidation stress is obtained.

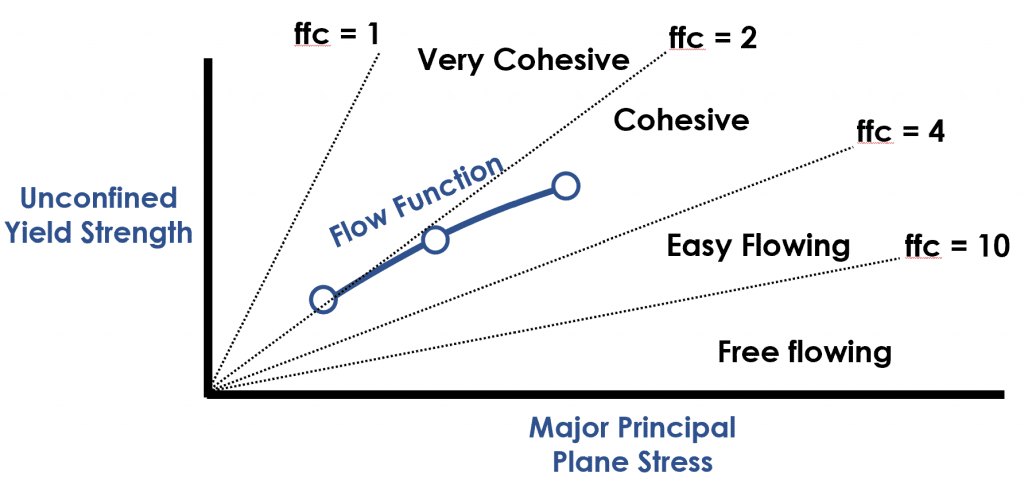

The process is repeated to generate a flow function for the powder, from which the flow function coefficient at a given consolidating stress can be referenced against established categories of flowability. These metrics make for a useful starting point in understanding and predicting powder handling behaviour when used in conjunction with metrics from complimentary powder characterisation techniques.

If you would like to learn more about this technique, please feel welcome to contact us.