At the Centre for Industrial Rheology, we are a specialised rheological testing lab that offers characterisation of ophthalmic viscosurgical devices (OVDs) in accordance with ISO 15798:2013. Equipped with a suite of high-performance research rheometers, we are able to provide rapid access to the rheological properties stated in this ISO, such as shear viscosity, absolute complex viscosity, and elasticity.

Whether you are developing a new OVD formulation or performing batch-to-batch quality control, rheology plays a vital role in determining how your product may behave when used.

Learn more about how we can support your OVD rheological needs

Introduction to Ophthalmic Viscosurgical Devices

Ophthalmic viscosurgical devices are viscoelastic materials that are commonly used in intraocular surgeries. Their significance in ophthalmic surgical procedures arises from their protective ability, and as such, they are used to fill the anterior chamber to maintain intraocular space. This protective ability is crucial in contributing to successful surgical outcomes.

OVDs are often characterised as either cohesive or dispersive:

Cohesive OVDs are typically long-chain molecules with high molecular weight and viscosity. Their high viscosity at low shear conditions allows them to maintain their position and resist dispersion within the anterior chamber during surgery. Under higher shear rates, they tend to remain interconnected and extrude from the eye as a cohesive mass, which eases surgical removal.

Dispersive OVDs are generally shorter chain molecules with low molecular weight and viscosity. These properties enable them to disperse under high shear, resulting in superior coating abilities and extensive protection of intraocular tissues. However, their tendency to adhere to intraocular surfaces can complicate complete removal at the end of surgery.

Rheological Testing of Ophthalmic Viscosurgical Devices in Accordance with ISO 15798:2013

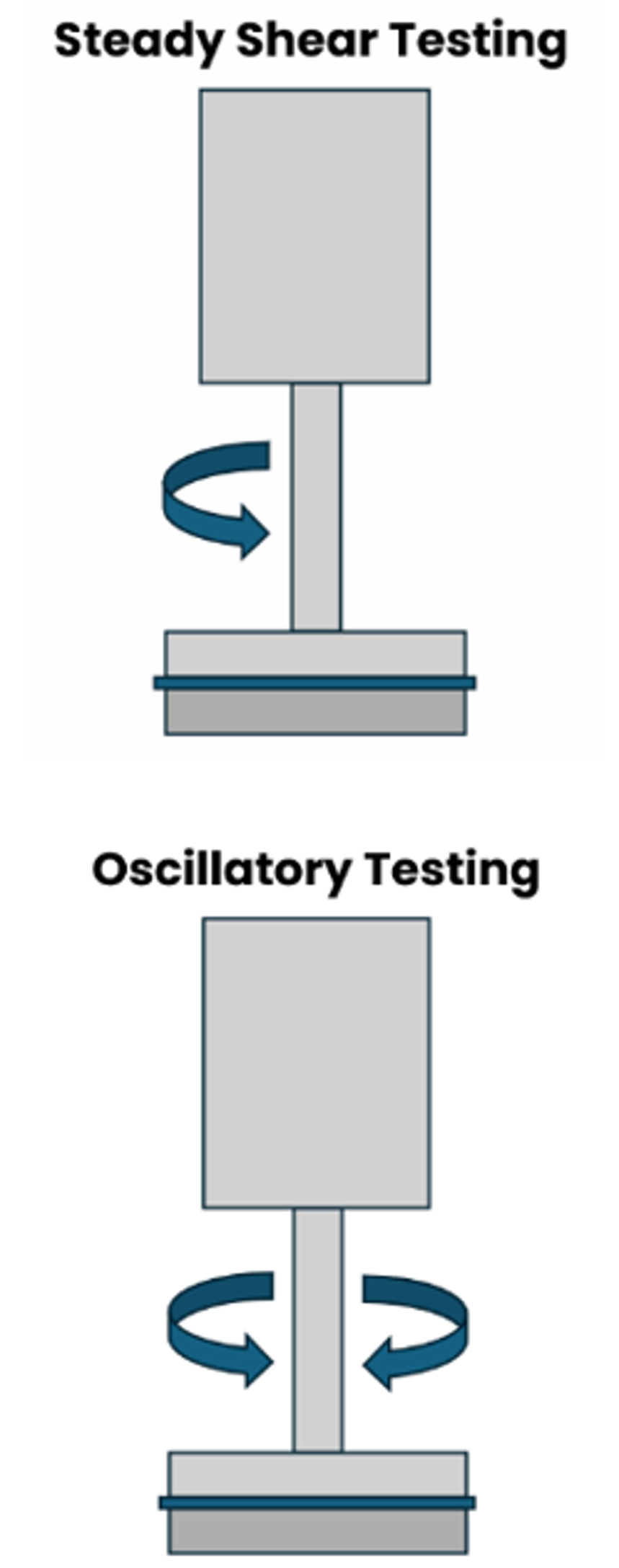

Rheological characterisation is essential for OVDs as their behaviour within the eye during surgery relies fundamentally on their rheological properties. At the Centre for Industrial Rheology, we can conduct rheological testing of OVDs in accordance with ISO 15798:2013. Rheological measurements are performed on a rotational rheometer, where a sample is placed between two surfaces, typically a cone-plate or parallel plate geometry. The upper surface moves while the lower surface remains stationary, allowing controlled deformation of the sample. Through this, two main types of testing can be employed: steady shear and oscillatory testing.

Steady shear testing involves applying continuous rotation to a sample to generate a constant shear rate. Shear rate is a measure of how quickly adjacent layers of a fluid move relative to each other, expressed in reciprocal seconds. The key parameter measured is the shear stress, which is the force per unit area required to move one layer of fluid over another, measured in Pascals. The shear viscosity is then calculated as the ratio of shear stress to shear rate, resulting in units of Pa·s.

Oscillatory testing involves applying small, sinusoidal deformations to probe a material’s viscoelastic properties, which describe how a material behaves like both a liquid and a solid. The key outputs are the storage modulus (G’) and loss modulus (G’’), both measured in Pascals. The storage modulus reflects the elastic, or “solid-like” component of the response, while the loss modulus represents the viscous or “liquid-like” component.

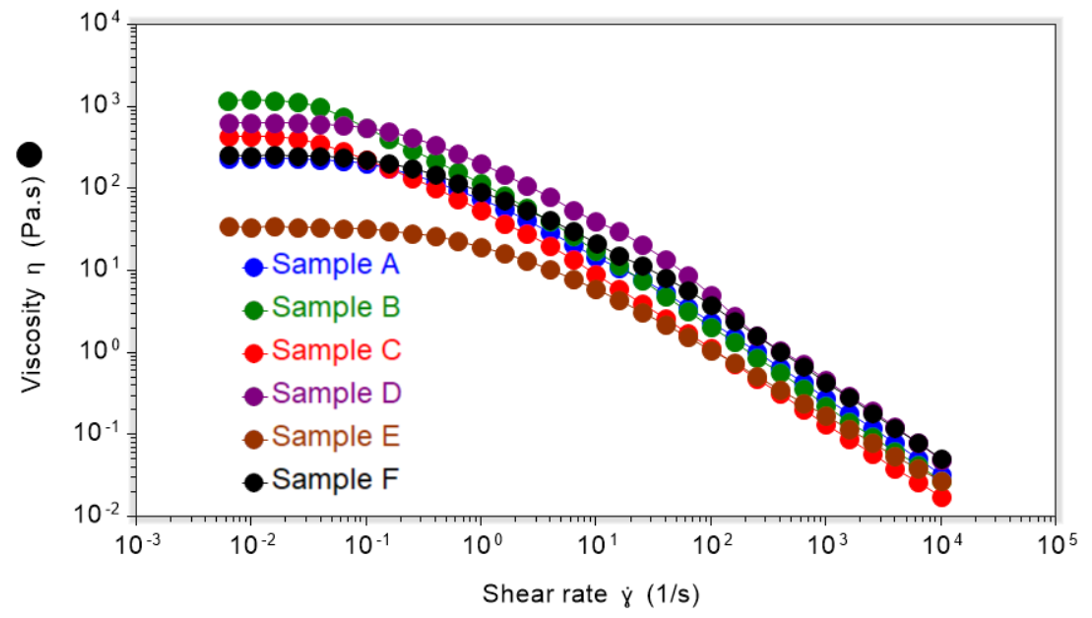

Shear Viscosity

Figure 3 shows how the viscosity of each OVD changes with increasing shear rates. All samples display non-Newtonian shear-thinning behaviour, with viscosity decreasing as shear rate increases. Notably, this measurement spans an exceptionally wide shear rate range spanning six orders of magnitude. Correspondingly, each sample demonstrates substantial decreases in viscosity; for example, sample B shows a reduction in viscosity of more than four orders of magnitude across the tested range. This shear-thinning behaviour is crucial for OVDs, as during injection, it is exposed to higher shear rates and thus, allows easy injection. However, at rest, it still maintains sufficient viscosity to support intraocular tissues.

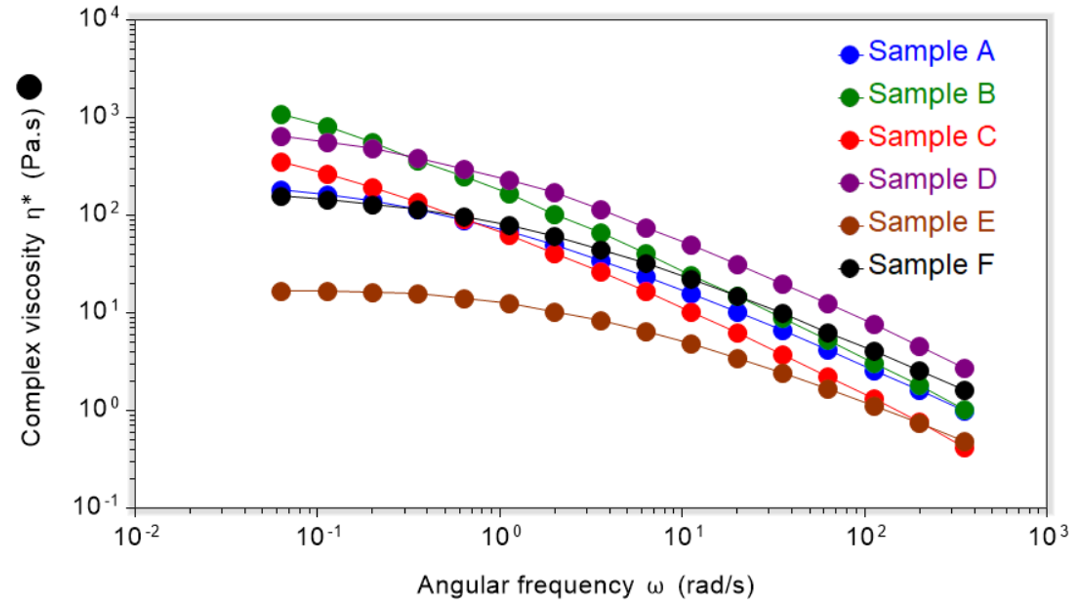

Absolute Complex Viscosity

Figure 4 shows the absolute complex viscosity as a function of angular frequency, obtained from an oscillatory frequency sweep. These tests are used to simultaneously demonstrate the resistance to flow and deformation of the OVD formulation based on how the material responds to small, sinusoidal deformations. Complex viscosity is calculated as the complex modulus divided by the angular frequency.

One key variable extracted from this technique is the zero-shear viscosity, effectively the viscosity of the OVD in a close-to-rest condition. At very low frequencies, the complex viscosity approaches the zero-shear viscosity. The results demonstrate substantial differences in the zero-shear viscosity. Sample B exhibits the highest zero-shear viscosity, while sample E shows the lowest, differing by more than two orders of magnitude.

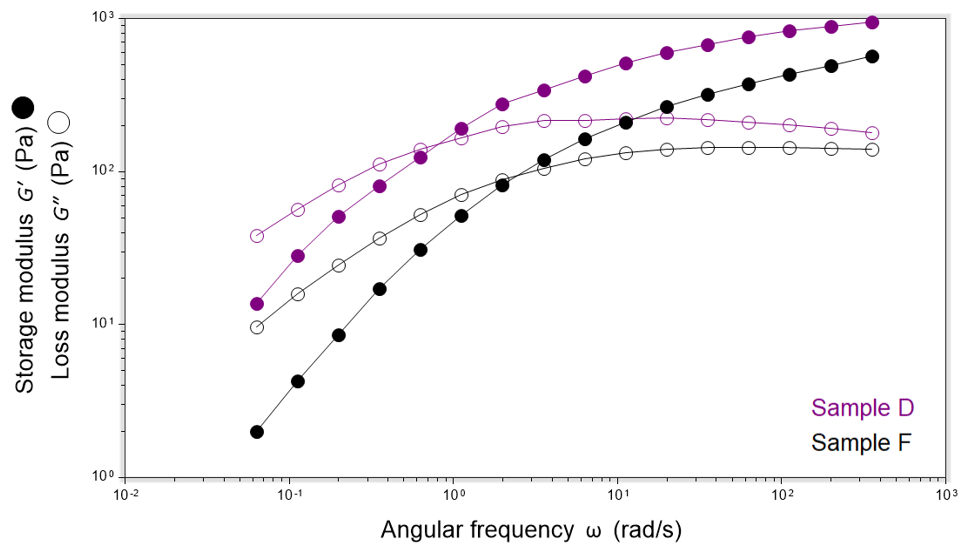

Elasticity

Figure 5 shows the viscoelastic behaviour of two different OVD samples, represented by their storage modulus (G’) and loss modulus (G’’) across a range of oscillatory frequencies. At lower frequencies, both samples exhibit a higher loss modulus, indicating dominant viscous behaviour. As the frequency increases, a crossover point is observed where G’ and G’’ intersect. Beyond this point, the storage modulus surpasses the loss modulus, signifying a shift toward elastic behaviour.

This reflects a timescale-dependent viscoelastic response characteristic of entangled polymer systems such as OVDs. At short timescales, or high frequencies, the polymer chains do not have sufficient time to disentangle or relax, so the material responds more elastically. At longer timescales, or lower frequencies, the chains can unravel and relax internal stresses, allowing the material to behave more like a viscous fluid.

The reciprocal of the crossover frequency corresponds to the material’s characteristic relaxation time, which is a measure of the time for the molecular and microstructural rearrangement process to relax internal stresses. Sample F has a higher crossover frequency than Sample D, and as such, has a shorter characteristic relaxation time. This shorter relaxation time suggests that sample F has a lower molecular weight, as lower molecular weight polymers can relax more quickly due to reduced chain entanglement.

Summary

These three rheological properties stated in ISO15798:2013 offer a comprehensive understanding of an OVD’s rheological behaviour, supporting formulation refinement and quality assurance in compliance with regulatory expectations.

Related Articles;

Not a dry eye in the house: Eye Drop Rheology

Unmasking the Mucoadhesive Properties of Ophthalmic Drops

Measuring Eye Drop Surface Tension

Wasif Altaf serves as an Applications Specialist at the Centre for Industrial Rheology, leveraging a chemical engineering background (BEng) to bridge theory and practice. His work focuses on advanced rheological characterisation.